ZYTR-50

Category:

Manual Series

- Product Description

-

Multiple Blade Options

Select from high-performance Metal, wear-resistant Ceramic, or lightweight Engineered Plastic blades to match your specific application requirements.

Imported Nano-Ceramic Rollers

Precision-engineered, our imported nano-ceramic rollers resist deformation, withstand wear, and enable easy cleaning.

Speed Adjustment Via Knob

Forward and reverse rotation control, simple to operate, featuring a DC motor with built-in speed controller.

Flexible Conformation, Precise Control

Featuring an articulating baffle block that adjusts freely for a perfect fit, with customizable pressure settings for broad applicability.

Application Scenarios

Product Highlights

- 1.The ZYTR-50 boasts remarkable performance coupled with a user-friendly design for effortless usage.

- 2.Powerful: Its exceptional motor power gives it a dominant edge over all its rivals.

- 3.Accurate: With the ability to adjust the rollers using just one hand, the ZYTR-50 ensures precise dispersion for optimal results.

- 4.The ZYTR-50 is a must-have equipment for laboratories or small-scale production.

- 5.Its compact frame takes up minimal space on the lab bench, while still providing operators with the flexibility to disperse a diverse range of products.

- 6.This particular unit has been specifically designed to handle volumes of no more than 5 liters within an hour.

Why Choose Us

Your Leading Three Roll Mill

Innovative Technology Solutions

Advanced technology and facilities enable us to offer the best value: top quality at competitive prices. We deliver both standard and custom solutions that meet your exact needs.

Professional Teams

Our sales and engineering teams can help with all phases of purchasing, including pre-sales consultation, testing, introducing solutions, customization, etc.

Superior Quality

We operate a quality management system that exceeds industry standards. Each process is embedded with precise control points, rigorously monitored from start to finish.

Time Efficiency

Our robust supply chain guarantees timely delivery of machine. We have rich experience in exporting goods, including documentary, shipping, customs clearance etc.

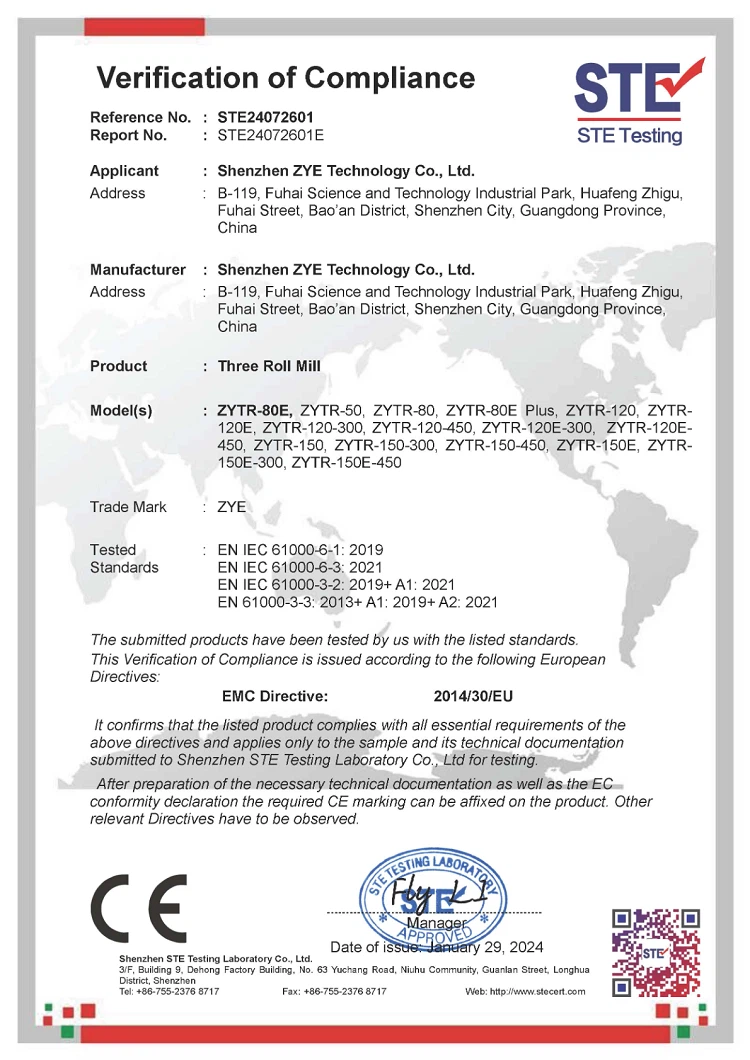

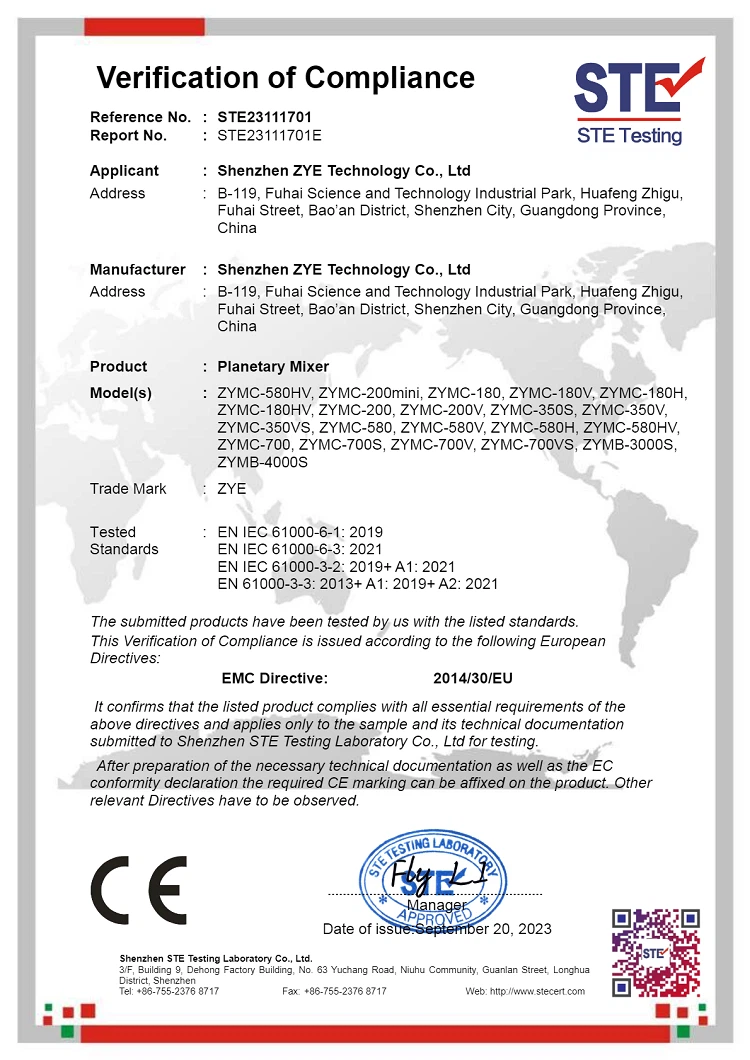

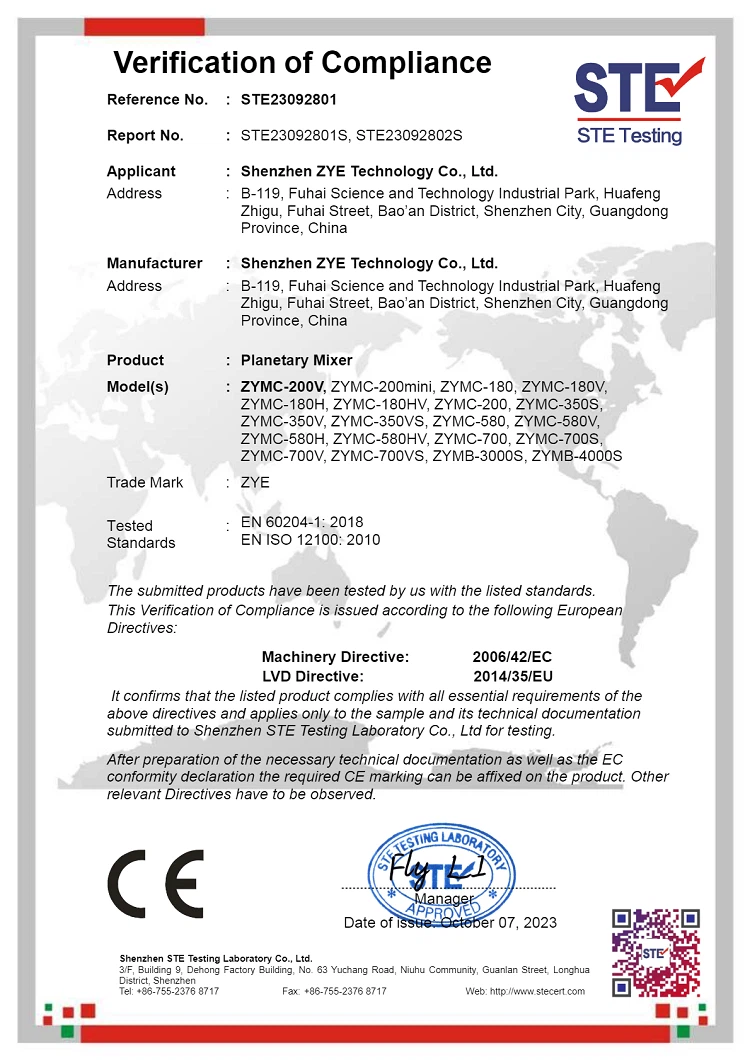

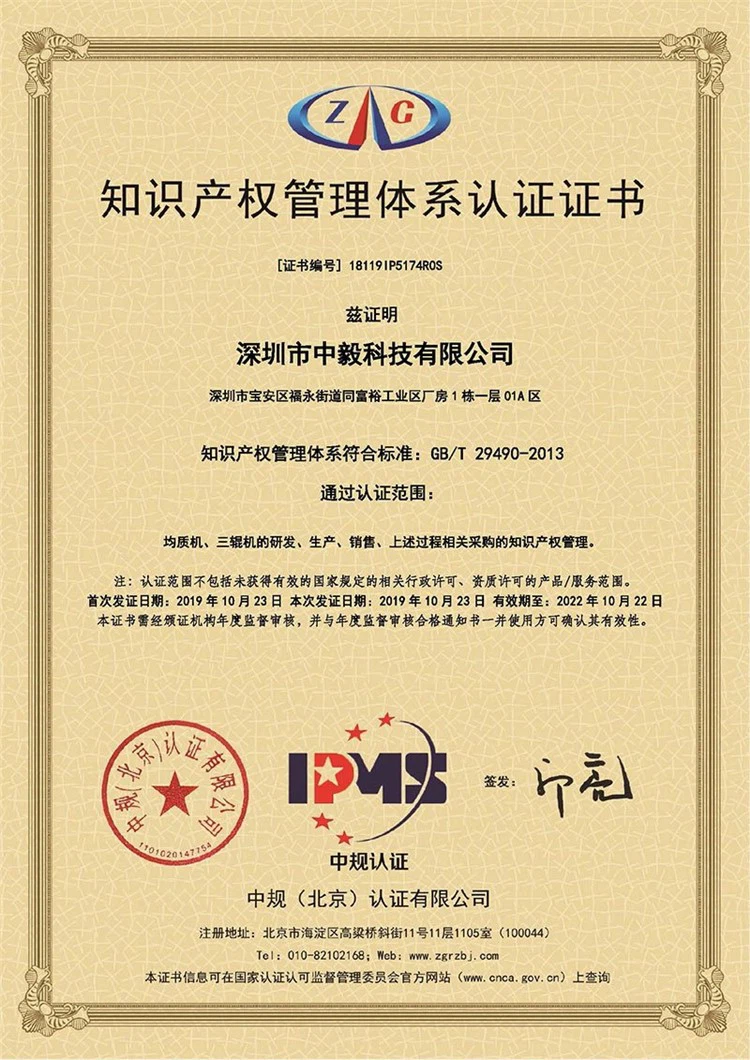

Qualification Of Automatic Three Roller Mill

Our Service

Consultation & Planning (Pre-Sale)

We work with you to define your exact needs. Through expert consultation, we provide technical advice and tailor a solution to ensure the equipment selection is precisely right for your application.

Precision Execution & Delivery (During Sale)

Upon order confirmation, we begin our rigorous process. From controlled manufacturing and comprehensive testing to secure packaging and shipping, every step is transparent and documented, guaranteeing you receive a fully qualified and intact machine.

Precision Execution & Delivery (During Sale)

Delivery marks the start of our long-term partnership. We provide complete installation support, a solid warranty, and commit to lifetime technical service with rapid response, aiming to be your reliable partner on the production line for years to come.

FAQ

Q: What Is Three Roll Mill Machine?

A: A three roll mill machine is a type of milling equipment used to refine materials. It operates by passing a material through a set of three horizontally positioned rollers that rotate in opposite directions and different speed. The rollers apply pressure and shear forces to the material, resulting in a uniform, finely dispersed final material. Three roll mill machines are commonly used in the production of cosmetics, inks, adhesives, food and electronics industries. They allow for precise control over particle size and consistency, making them a crucial tool for industries that require high-quality final products. They are also versatile and can handle a wide range of materials, from low viscosity fluids to high viscosity and density pastes and gels.Q: What Are The Advantages Of Three Roll Mill?

A: Three roll mills are essential equipment in the manufacturing industry. The benefits of using this machine are numerous and include the following: 1. Uniform mixing: Three roll mills ensure that all ingredients are thoroughly mixed, resulting in a more consistent and better quality product. 2. Improved product quality: By using three roll mills, products can be refined to a higher degree of consistency and uniformity. This ensures that the end product is of premium quality, which is of great importance in various industries. 3. Cost-effective: Three roll mills are cost-effective and give excellent returns on your investment. Since they can handle a wide range of materials, such as paints, inks, and adhesives, one machine can serve multiple purposes. 4. Time-saving: With a constant flow of ingredients and automated processes, three roll mills save time and improve productivity. This means that more work can be done in less time, which translates into increased profitability. Overall, three roll mills are a smart investment for manufacturers, providing a range of advantages that improve product quality, efficiency, and profitability.Q: Are There Limitations Of Three Roll Mill?

A: Three roll mills are versatile machines that are used in a variety of industries to mix, refine, and homogenize materials. However, like any piece of equipment, they do have limitations. Here are a few key limitations to keep in mind when using a three roll mill: 1. Material Properties: The three roll mill is best suited for materials that are low to medium high viscosity. If the material is too thick or too runny, it may not behave as expected during the milling process. 2. Particle Size: Three roll mills are not ideal for milling materials with large particles or agglomerates. They are best suited for materials that have already been finely ground and only require further refinement. 3. Capacity: Three roll mills are generally designed for small to medium-sized batches. If you need to process a large quantity of material, you may need to invest in a different type of milling equipment. 4. Maintenance: Like any machine, a three roll mill requires regular maintenance to maintain optimal performance. This includes cleaning, lubrication, and periodic replacement of parts. Overall, three roll mills are excellent tools for many applications, but it's important to understand their limitations to avoid disappointment or damage to the equipment.Q: What Is Three Roll Mill Used For?

A: A three roll mill is a milling machine that uses three horizontally positioned rollers to grind and disperse materials. It is commonly used in the production of electro pastes, new materials, cosmetics, and other products that require uniform particle size reduction. The three rollers rotate at different speeds, with the materials passing through the gap between them. This process results in high shear forces that allow for thorough blending and dispersion of the materials. Three roll mills offer several advantages over other milling machines, including efficient mixing, precise control of particle size, and easy cleaning. They are also capable of handling high-viscosity materials and can be used for both batch and continuous processing. Overall, three roll mills are a versatile tool for the production of a wide range of products in various industries.Q: How Does Three Roll Mill Work?

A: A three roll mill is a mechanical device used to reduce particle size and homogenize materials. The three rolls rotate at varying speeds and they're positioned at different distances from each other. The material is fed between the first roll and the second roll, and the material that passes between them is passed through the gap between the second and third rolls. As the material passes through the rolls, it's progressively reduced in size and becomes a homogeneous paste. The three roll mill is an effective tool for processing fine materials, such as adhesive, silver paste and pigments. In addition to its effectiveness, the three roll mill is also relatively easy to operate and maintain. To start the mill, you simply load the material onto the feed hopper and adjust the gap between the rolls. Once the material is in place, you can turn on the machine and begin milling. Overall, the three roll mill is a reliable and efficient tool for producing high-quality materials.

Related Products

Product Inquiry

Our staff will contact you within 24 hours (working days)