Application Of Carbon Nanotube - Grinding And Dispersing Process

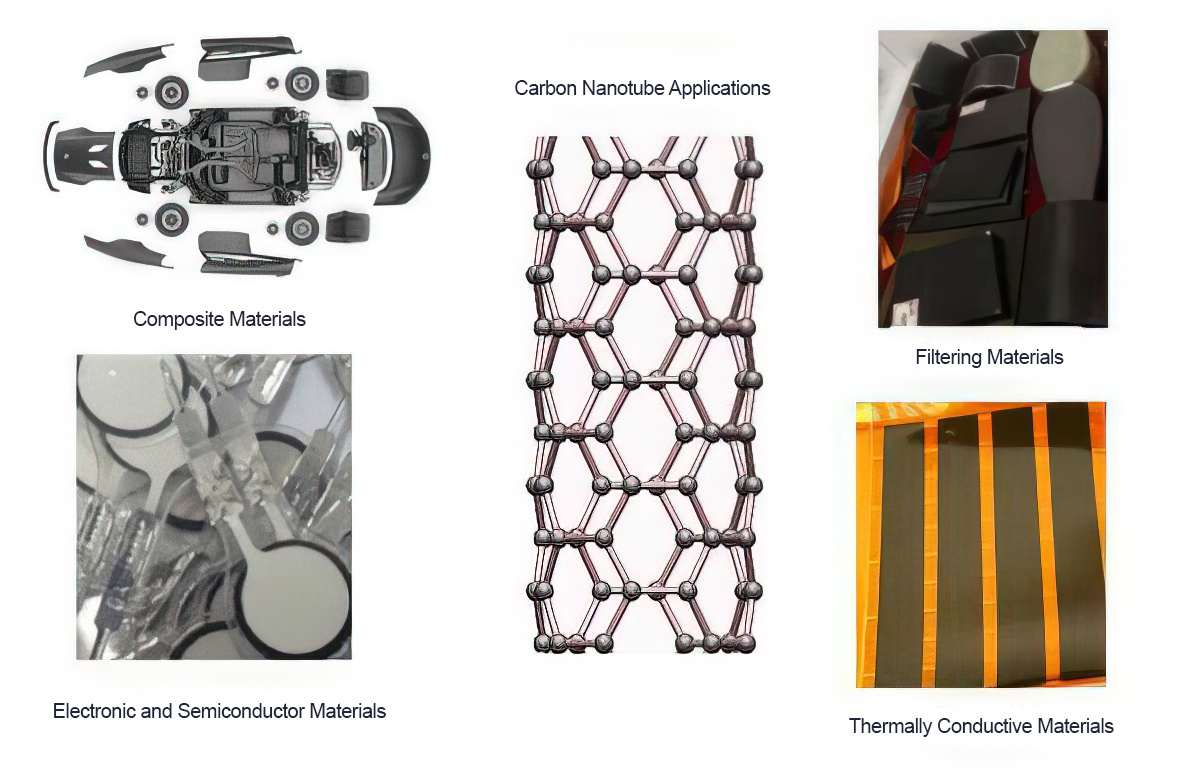

Carbon nanotubes (CNTs) are a new type of graphite material, which is a cylindrical structure formed by curling graphite flakes. It is a cylindrical structure made of curled layers of graphite flakes with a diameter ranging from one to several hundred nanometres, and its main applications are as follows:

Agglomeration And Dispersion Problems:

Although carbon nanotubes have excellent physical properties, the existence of their agglomerate form and the surface chemistry of carbon, making the mixing of carbon nanotubes with other material matrixes a difficult problem.

Recommended Process:

In order to make full use of the properties of single carbon nanotubes, it is necessary to disperse the carbon nanotubes homogeneously in the target matrix material, and use the carbon nanotubes as a base material. In the target matrix material, using physical methods such as shear mixing and grinding to effectively disperse the carbon nanotubes in the matrix.

Application Example:

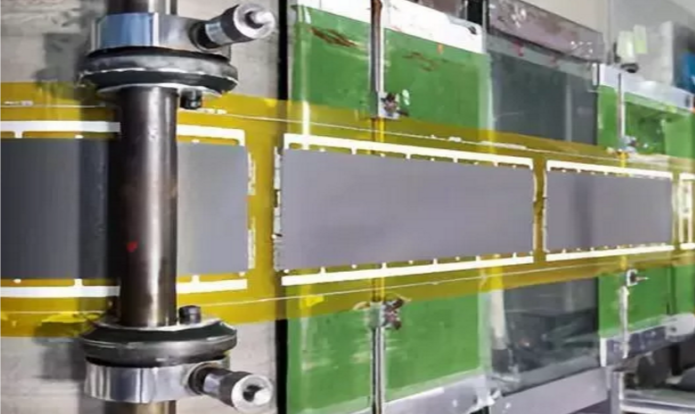

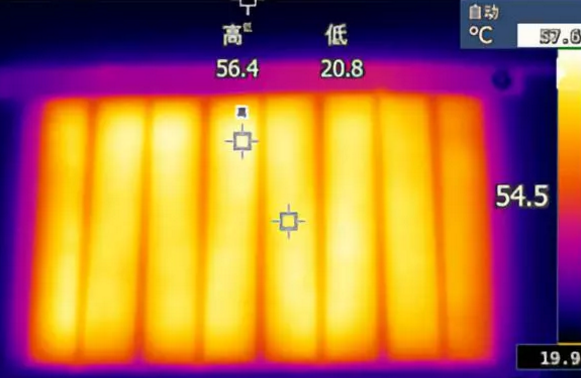

Carbon conductive paste, using high quality carbon nanotubes as the key functional filler, using water-based high functionality environmentally friendly resins as the base material, using water-based high functionality environmentally friendly resins as the base material. Highly functional and environmentally friendly resin, pure water as solvent, and add the appropriate proportion of imported carbon black as an auxiliary material. Using the mixing and defoaming technology of ZYE homogeneous machine and the high-efficiency dispersing function of ZYE three-roller machine, the slurry is homogeneous and stable. The homogeneity and stability of the slurry is achieved to produce conductive film for electric heating or shielding with excellent performance.

This process ensures consistent product quality and excellent performance without the addition of any metallic conductive fillers, and ensures adhesion with a low square footage resistance as low as 6.5Ω@25.4um.

Shenzhen ZYE Technology Co., Ltd.

No. 1268 Jiaotong Road, Wujiang Economic and Technological Development Zone, Suzhou (factory)

Building B, Fuhai Science and Technology Industrial Park, Huafeng Zhigu, Fuhai Street, Bao' an District, Shenzhen (factory)

Contact Us

Social media

Whatsapp: +8613682681189

Wechat: +8613682681189

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

©2025 Suzhou ZYE Precision Technology Co., Ltd. Powered by www.300.cn SEO Privacy Policy