Products

Focus on full chain solutions for core mixing and dispersion technologies

Products

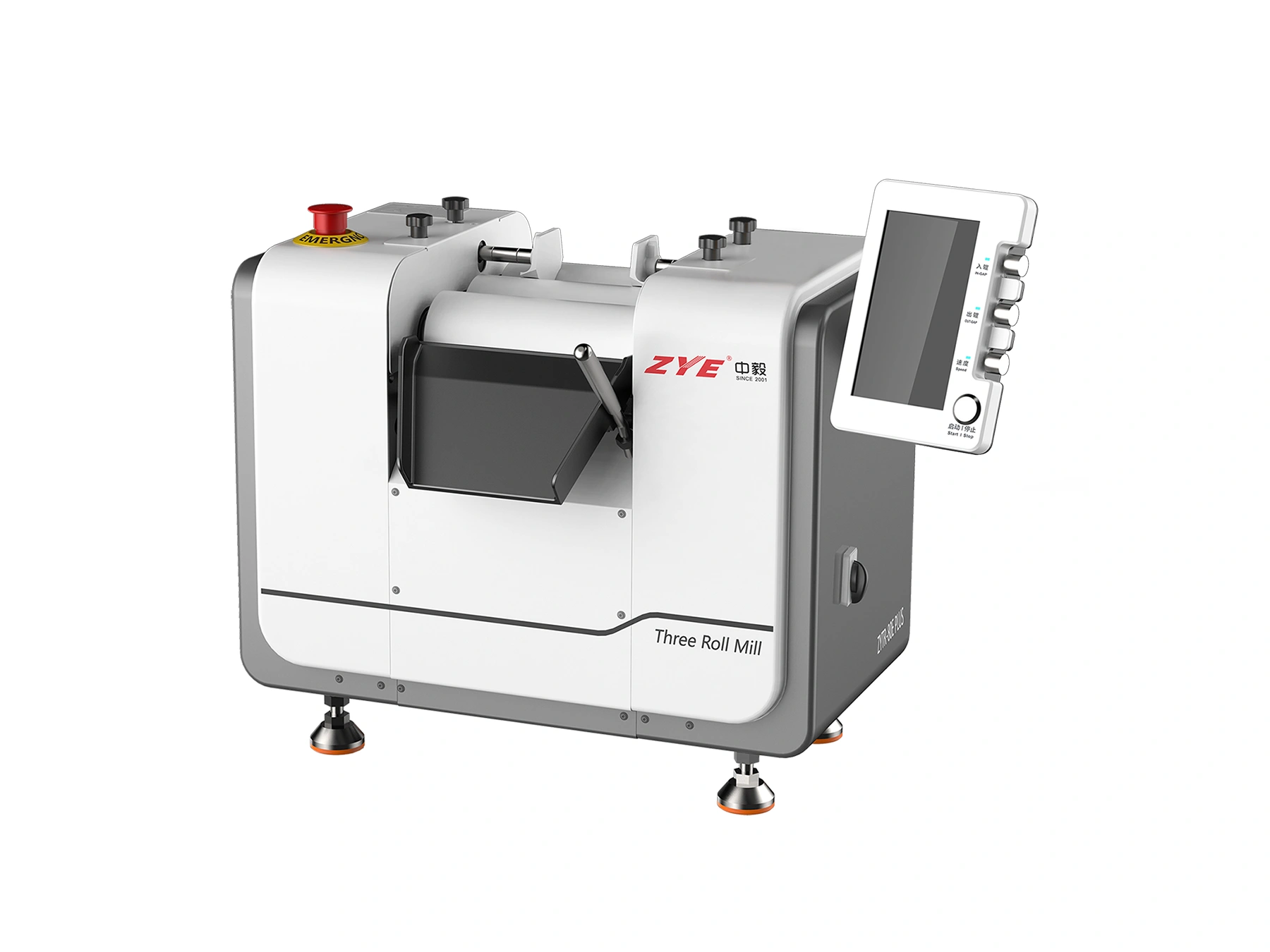

Wear-resistant rollers, adjustable speed and user-friendly operation ensure efficient particle size uniformity and superior fineness, deliver reliable results with stable performance. Ideal for labs and small-batch production.

Features electronic control for ultimate process efficiency and repeatability. Equipped with a smart dispersion display for real-time monitoring and adjustment. Provides unprecedented insight into the dispersion process.

Hydraulic system enables precise pressure and gap control for ultra-fine grinding. Excels in processing high-viscosity materials with high automation. Built to meet demanding production environments.

A small defoaming mixer is a countertop-sized unit that processes batch sizes from 150 g to 1400 g. It's perfect for rapidly formulating R&D test batches or specialty production.

A large-scale defoaming mixer can handle mixes of up to 40kg, making it ideal for larger production runs. Turn over batches faster, with no cleanup, and elevate your production capabilities.

100kg=20min. This vacuum defoamer breaks through the industry's production throughput limit. Its innovative bladeless design overturns the inefficiencies of traditional dual planetary mixing.

Ultra-high centrifugal force ensures superior defoaming results, Compatible with 3000 mL syringes and customizable adapter options. Supports both single and dual-component material processing.

Designed for precise filling of high-viscosity materials with parameter storage. Adaptable to various syringe types with customizable adapter configurations. Ensures quantitative accuracy and repeatable performance.

Comprehensive support for ZYE equipment with versatile component options. Scraper sockets available in wide and narrow ends; scraping knives in stainless steel, polyester, or ceramic. Guide plates with multiple materials and adjustment methods.