Dispersion in Lipstick and Lip Gloss

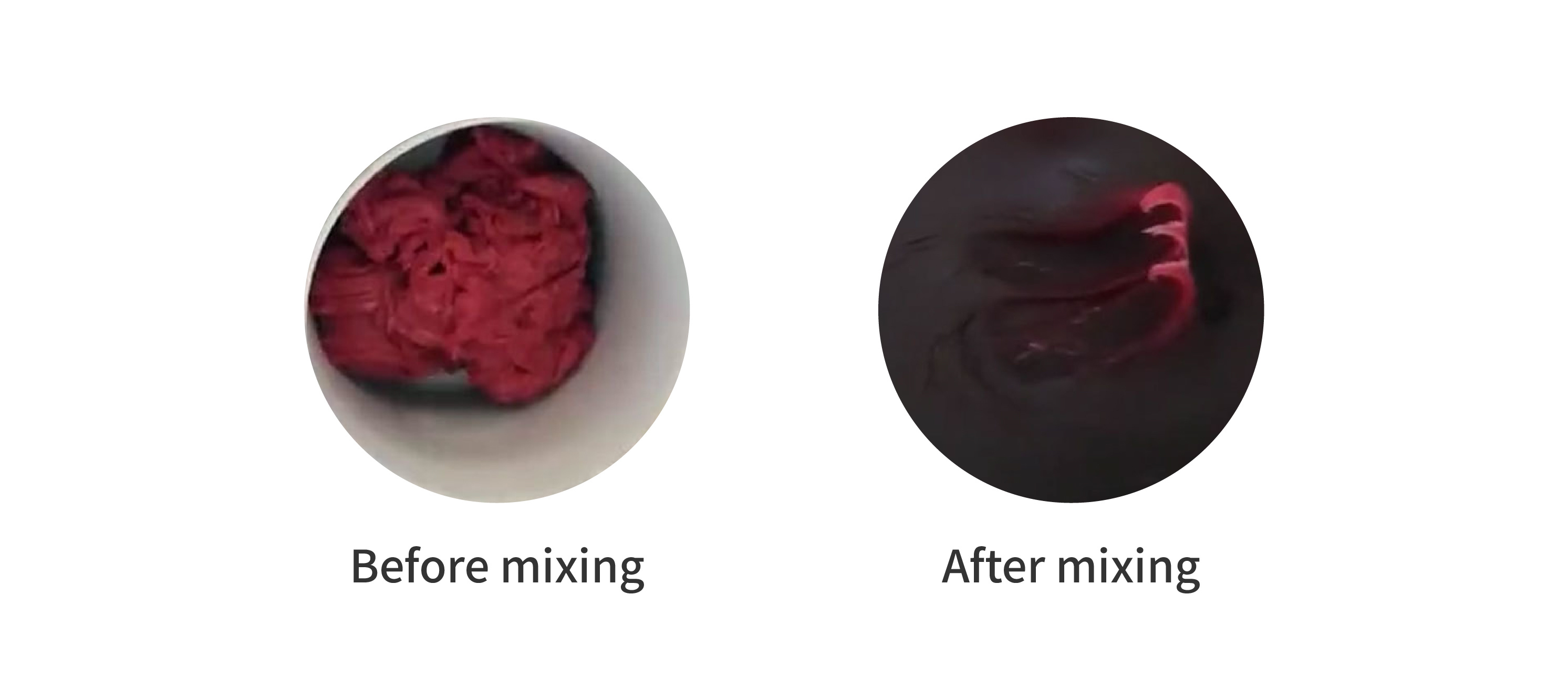

In lipstick and lip gloss, both ultra-fine particles and coarse particles can have a high percentage content. This is because some particles may be repeatedly dispersed due to the action of dispersion forces, while others are not dispersed at all.

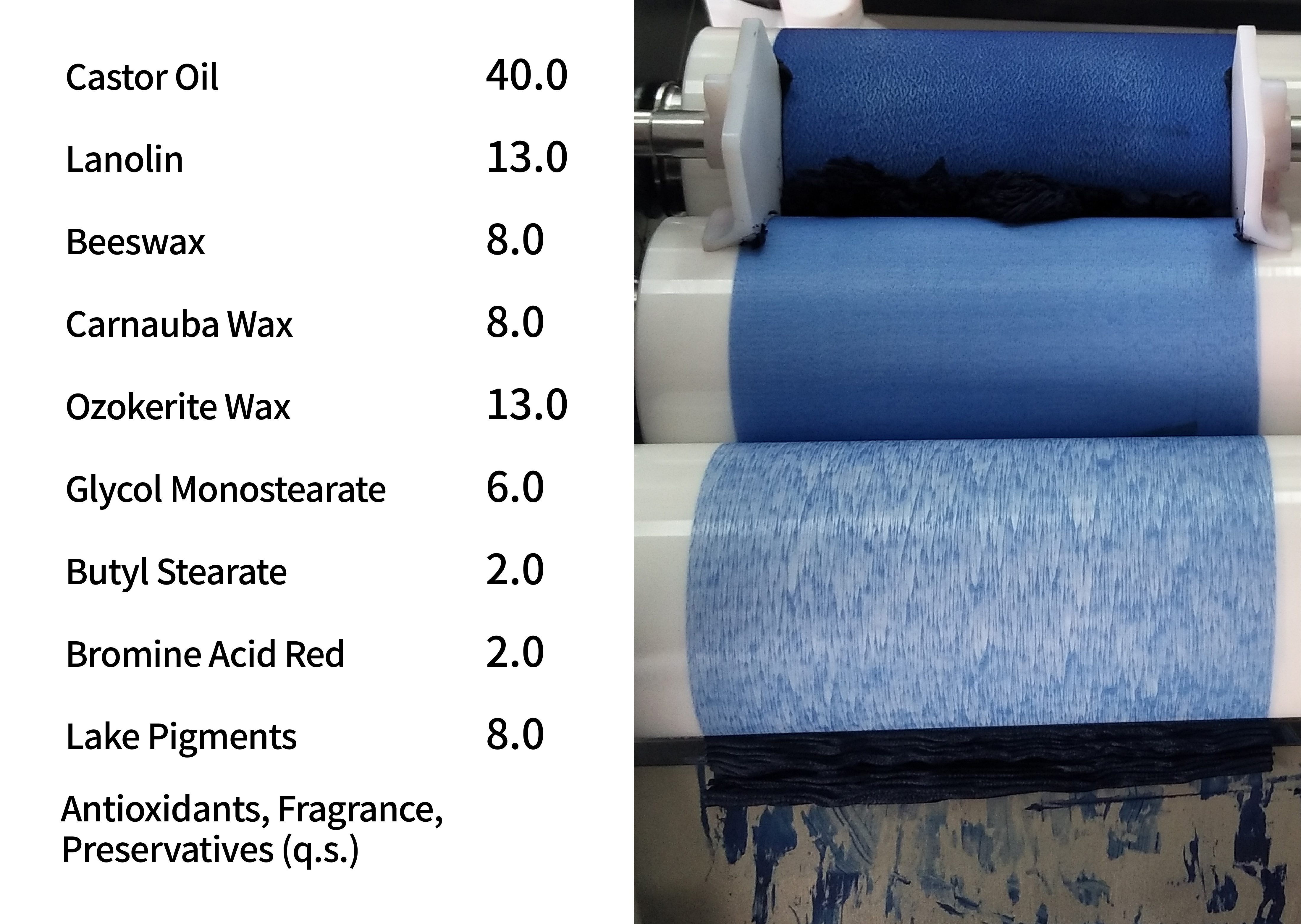

The three roll mill is the most effective dispersion equipment. In every three roll mill, the reduction in particle size and the dispersion of agglomerates are accomplished by the combined action of the crushing pressure between the rolls and the high shear force caused by the different rotational speeds of the rolls. Because the entire material is filled into the gap between the rolls, the particle size is precisely controllable and has a narrow distribution. By adjusting the roll gap, the particle size can be easily and accurately processed to the micron level. Therefore, compared to other grinding equipment, the three roll mill can effectively improve the particle size distribution, making the particle size distribution more concentrated.

Introduction to Cosmetic Dispersion Solutions

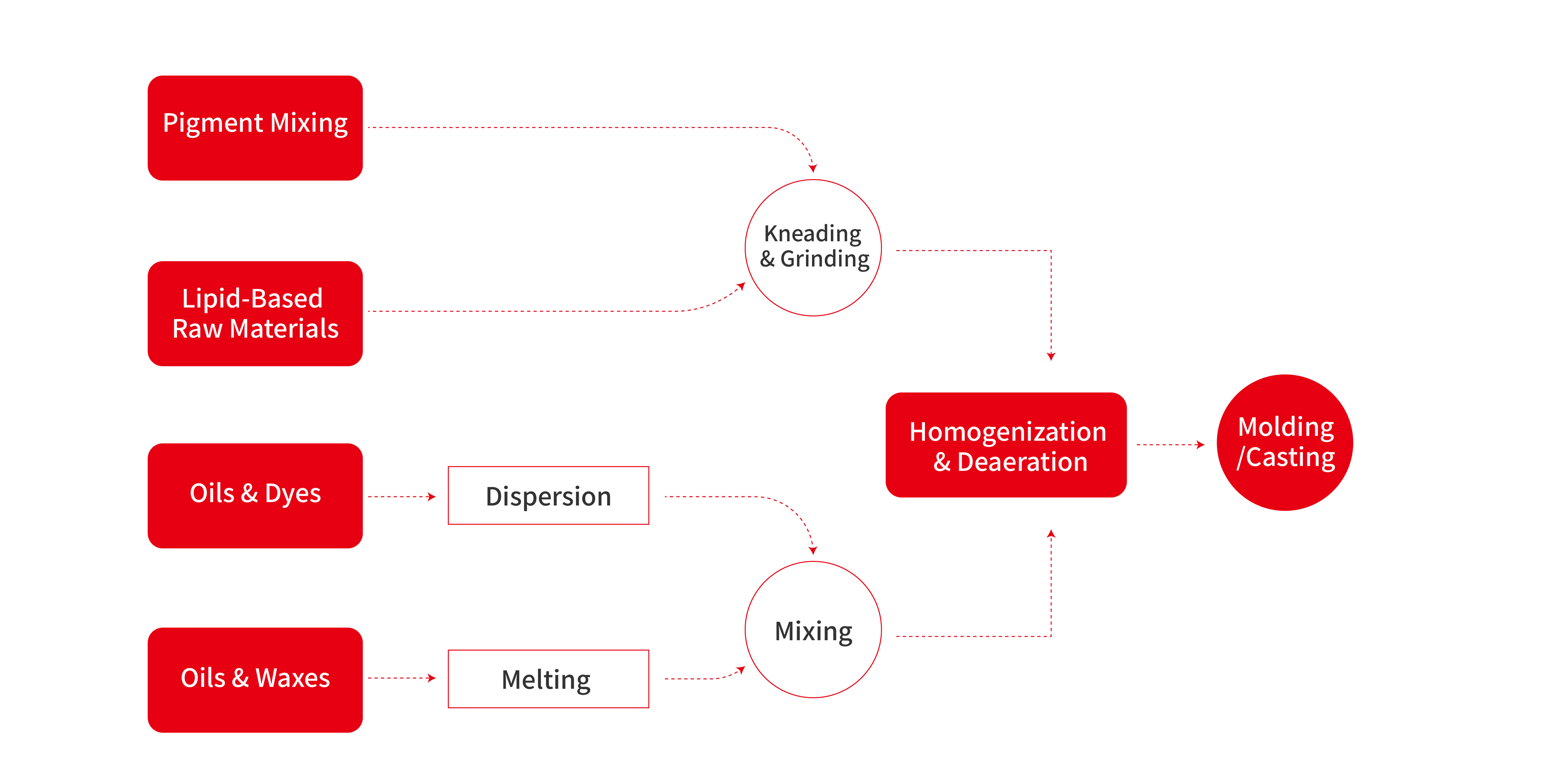

Schematic Diagram of Lipstick Process Flow

A Well-Known Domestic Cosmetics Production Company

Before and After Mixing

Lipstick ground by three roll mill

Problem Points in Preparation:

Pigment grinding: Since pigments are mostly powder, although the particles are relatively fine, they often agglomerate into clumps. It is difficult to disperse them evenly when directly adding them into the lipid base. Therefore, the pigments used must be ground beforehand. To make the grinding proceed smoothly, a small amount of liquid oil is often added to the pigment for mixing, and then mechanical grinding is used.

Mixing colorant and lipid base: Generally, the dye is first added into a solvent and heated to melt. Then, the ground pigment and wax raw materials are added, and after melting, semi-solid oils are added, stirred evenly, and grinding is performed while hot. After degassing, auxiliary materials such as fragrance are added.

Case: Colored Lipstick – Ingredients (Added Amount W%)

(Provided by a cosmetics customer)

Process Recommendation: Utilize ZYE mixing and grinding technology. First, fully and uniformly mix oils, waxes, softeners, colorants, fragrances, etc., using a high-speed non-intrusive method. Then, use the high shear force of physical methods to grind and disperse the agglomerates, further improving the fineness, resulting in a smoother application feel.

Recent Applications