Dispersion Of α-cyanoacrylate Eyelash Glue

Modern makeup products are popular all over the world and in high demand. False eyelash grafting glue is a kind of eyelash makeup products with broad market prospects. In the pursuit of beauty, many women will choose eyelash grafting to make eyelashes more complete and full, increase the charm and attractiveness of the eyes.

At present, eyelash glue is basically divided into two categories, one is water-based eyelash glue, and the other is α-cyanoacrylate. Among them, α-cyanoacrylate glue is often composed of α-cyanoacrylate resin as a base and carbon black powder and other auxiliaries. And the dispersion uniformity of carbon black and auxiliaries is likely to affect the adhesion and durability of the glue.

To solve the above problems, we use the ZYTR-50 three rolling mill developed and launched by ZYE to evenly disperse α-cyanoacrylate eyelash glue. ZYE's three rolling mill achieves the effect of grinding dispersion through the horizontal three roller surface extrusion, different steering and speed generated by the shear force. ZYE three rolling mill's precision spacing control does not damage the surface topography of the material to achieve the purpose of depolymerization.

Experimental equipment: ZYTR-50 three rolling mill (zirconia roller) + metal blade + laser particle size analyzer (wet method)

Experimental material: α-cyanoacrylate resin + carbon black + additive

Experimental purpose: to make the material dispersion more uniform by grinding with three rollers

Experimental steps:

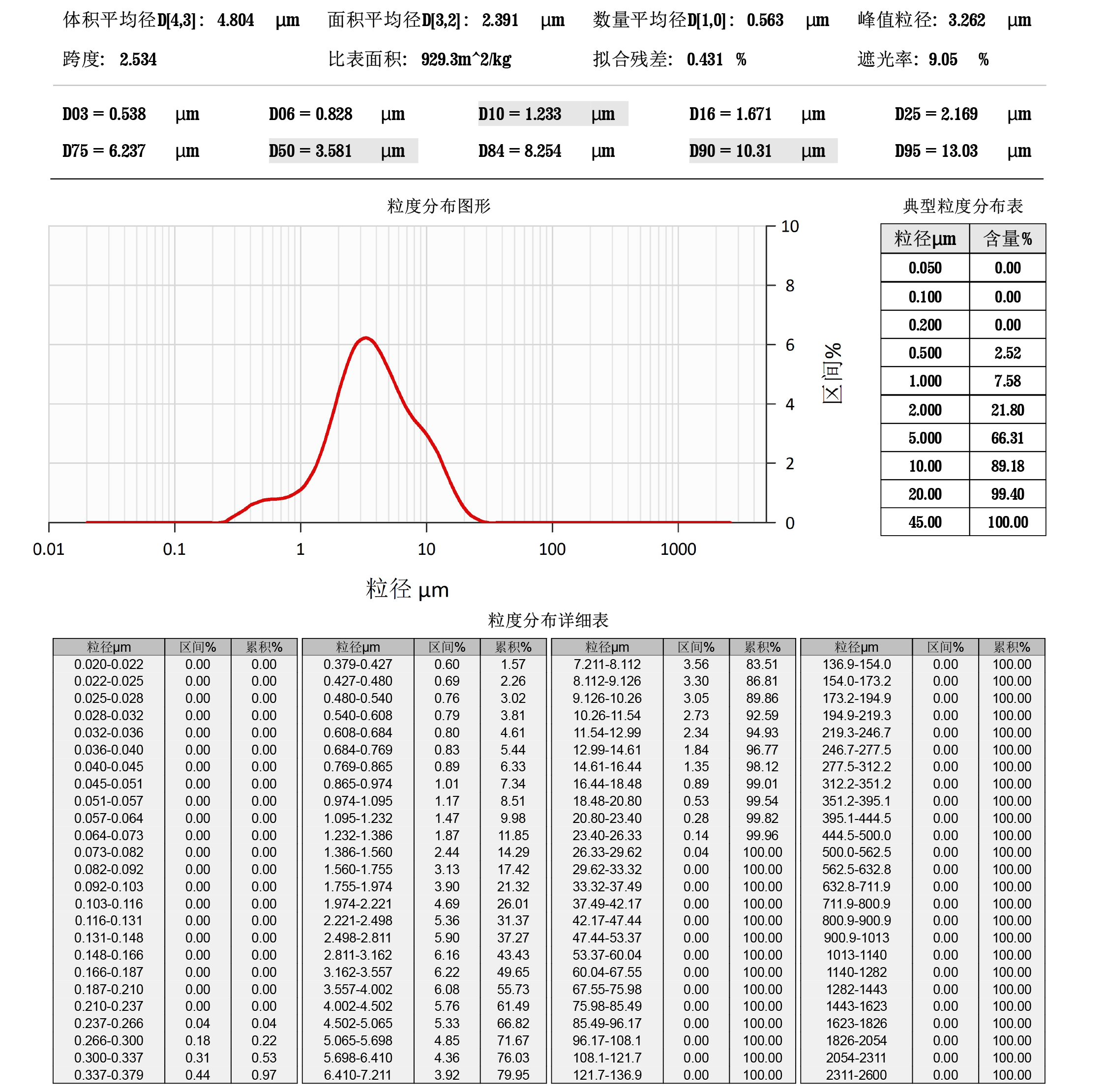

1. Take a small amount of premixed material and use the laser particle size analyzer wet component to detect the initial particle size of the glue (D50:3.5 microns D90:10.3 microns)

2. Use ZYTR-50 three rolling mill to get the paste. The whole paste is more delicate and shiny. The discharge was uniform without leakage during the operation.

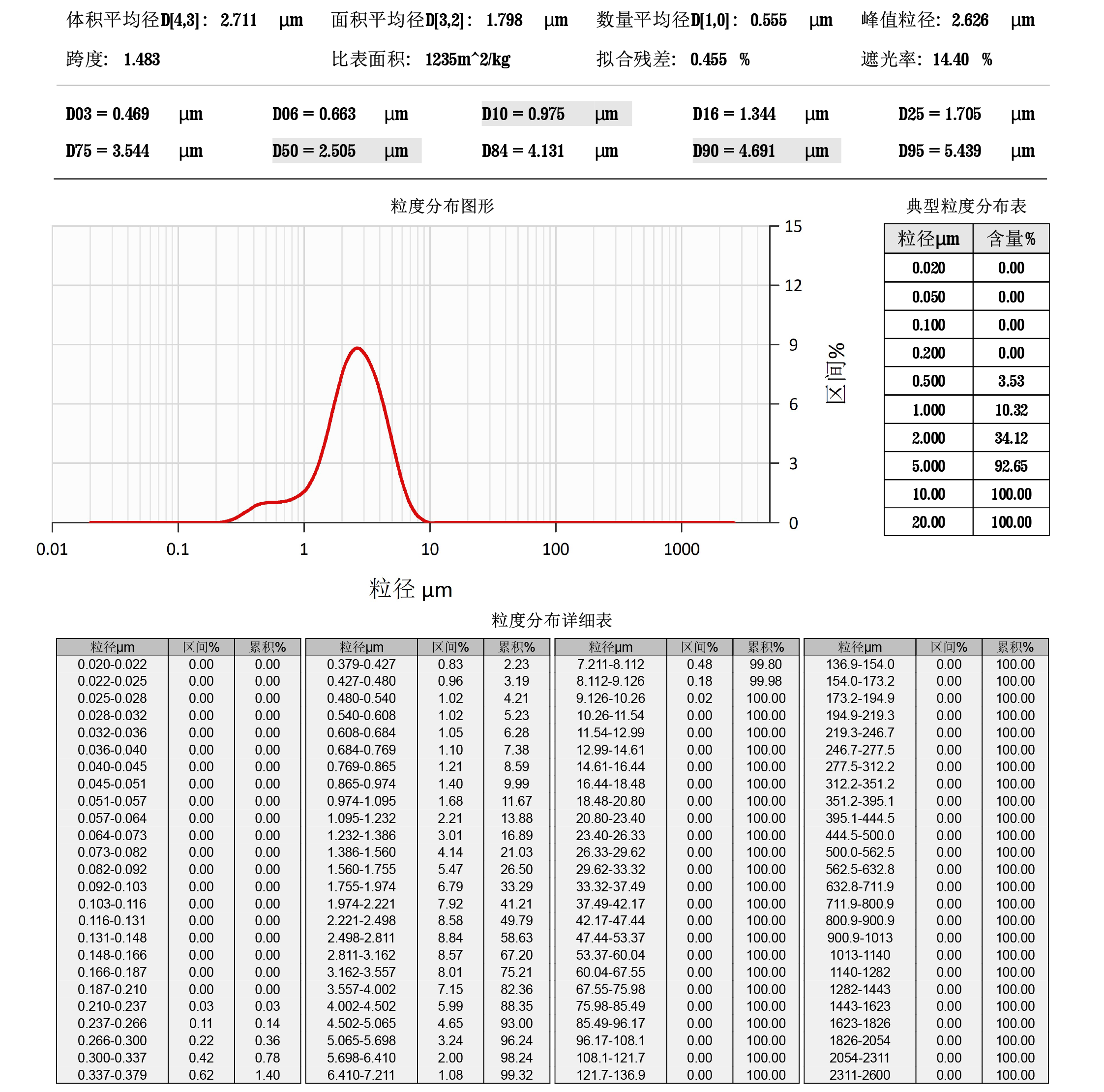

3. Take a small amount of ground material and then use the laser particle size analyzer wet component to detect the particle size (D50:2.5 microns D90:4.6 microns)

Experimental data:

Particle size analysis report - without grinding by ZYTR-50

Particle size analysis report - grinding by ZYTR-50

Experimental analysis:

After grinding with ZYTR-50 three rolling mill, it can be seen by comparing the detection results of particle size analyzer:

1, the overall particle size of the material is reduced;

2. D50 is closer to D90 after grinding, indicating a more concentrated particle size distribution;

3. The increase of the specific surface area of the material means that the powder is infiltrated more fully and the dispersion is more uniform.

Suzhou ZYE Company Profile:

ZYE was founded in 2007 and is a precision equipment manufacturer in a highly specialized niche in China. We specialize in the R&D, manufacturing, and sales of mixing, dispersing, defoaming, filling, coating, and inspection/preparation technologies, dedicated to providing customers with full-chain solutions. Our equipment is widely used in fields such as adhesives, inks & coatings, electronics industry, electronic pastes, new energy, nano new materials, pharmaceuticals, and cosmetics.

Currently, we have over 2,000 domestic and international cooperative customers, have accumulated more than 10,000 experimental reports and records, and our equipment is distributed across more than 30 countries worldwide, including Germany, the UK, France, Switzerland, the USA, Canada, Japan, South Korea, Israel, Singapore, and Malaysia.

After nearly 15 years of refinement and积淀 (accumulated experience), ZYE has obtained more than 100 patents, software copyrights, trademarks, and certifications. We are also recognized as a National High-Tech Enterprise and a Specialized, Refined, Unique, and New SME.

ZYE adheres to the principle of being customer-application-centered and people-oriented, valuing dedicated strivers. We aim to build a high-end brand in the industry, following the path of "Brand and Quality," and strive to contribute to the achievement of Chinese equipment manufacturing.

Advantages of Suzhou ZYE Three-Roll Mills:

√ High-precision grinding (Minimum achievable fineness can reach below 1μm, subject to material properties)

√ Imported nano-level ceramic rollers, easy to clean

√ Stepless speed regulation

√ Optional feeding hopper

√ Single-handle control of roller gap, balanced torque, easy operation

√ Ceramic Roller Precision: Concentricity <2μm, Straightness <2μm, Surface Roughness <0.3μm

Contact Information:

Suzhou ZYE Precision Technology Co., Ltd.

Address: No. 1268 Jiaotong Road, Wujiang Economic Development Zone, Suzhou

Tel: 0512-63438838

Email: sales@zyegroup.com

Recent Applications