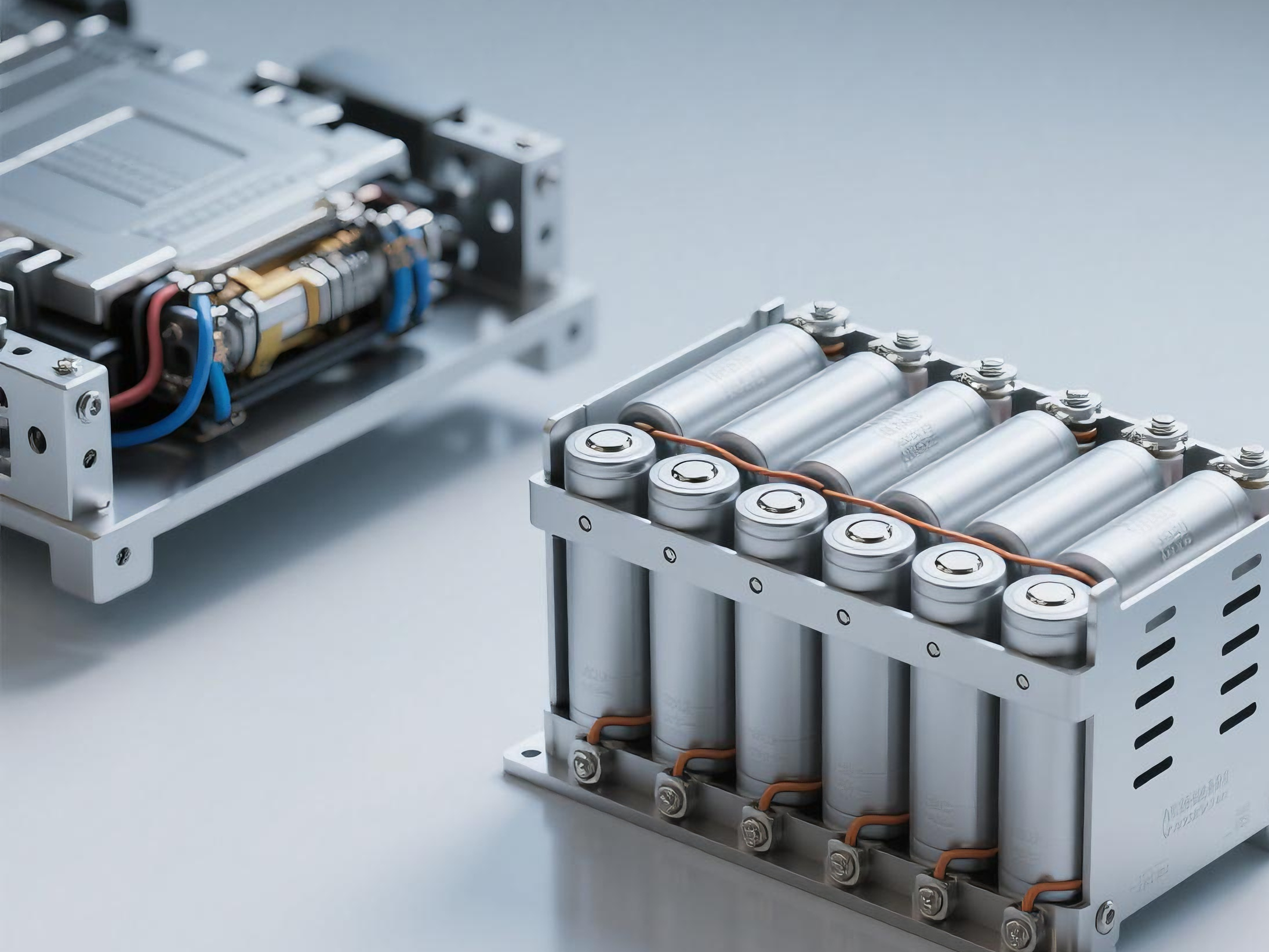

Solid Oxide Fuel Cell Manufacturing Solution: Powering the Green Upgrade of the New Energy Battery Industry

Driven by the global "Dual Carbon" goals and the transformation of the energy structure, the new energy battery industry is entering a critical period of rapid development and technological iteration. The Solid Oxide Fuel Cell (SOFC), as a highly efficient and clean energy conversion device, offers significant advantages such as high energy conversion efficiency and broad fuel adaptability. It demonstrates vast application potential in distributed power generation, backup power supplies, and transportation.

However, the widespread adoption of SOFCs still faces numerous challenges. Among these, the quality of electrode slurry preparation is a key factor limiting their performance and stability. Issues like powder agglomeration and trapped air bubbles within the electrode slurry directly impact the cell's electrochemical performance, interfacial adhesion, and long-term operational reliability. Therefore, an efficient and precise manufacturing solution is urgently needed to break through these technical bottlenecks.

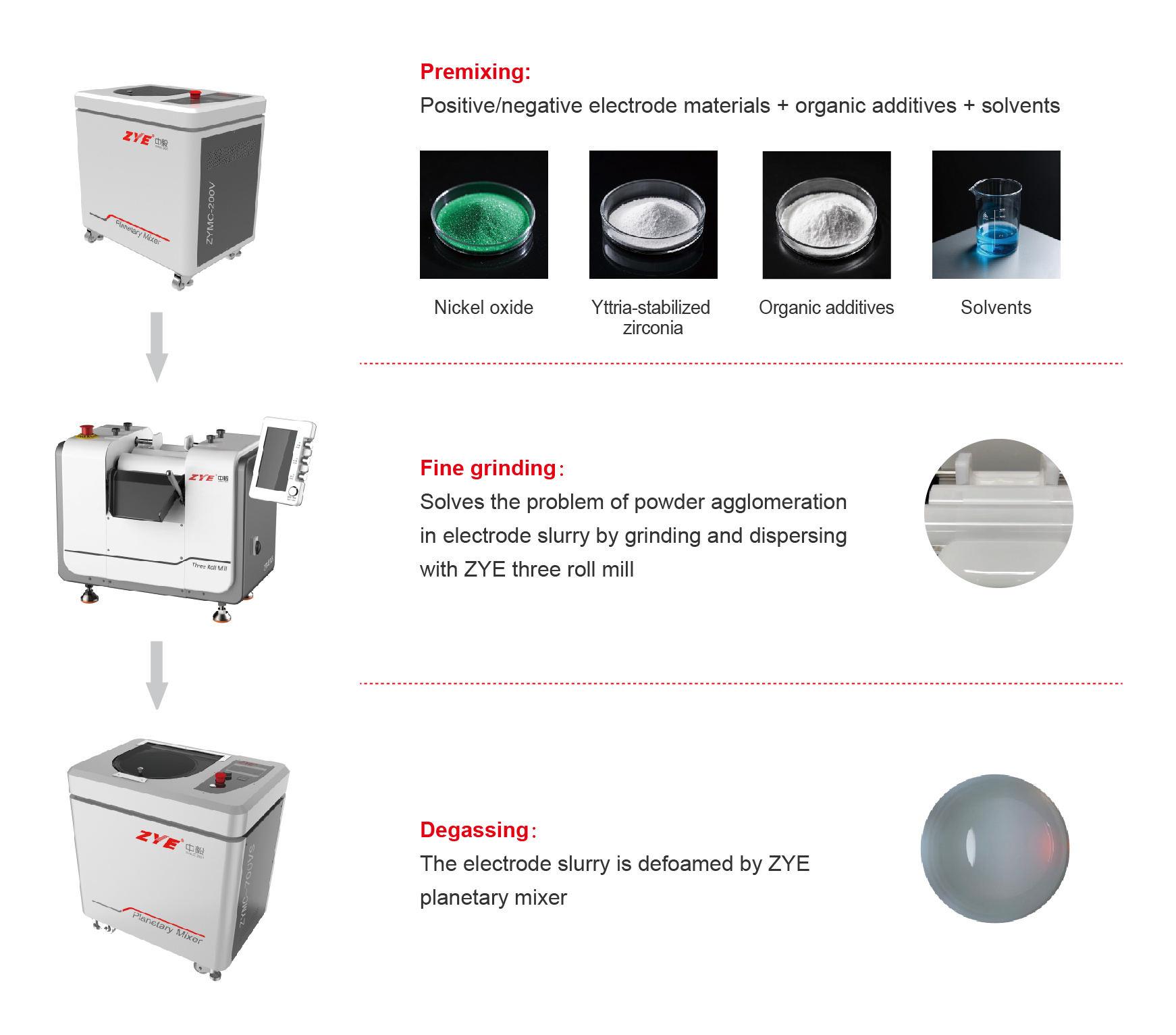

Addressing the pain points in SOFC electrode slurry preparation, this paper proposes a comprehensive process solution based on pre-mixing → fine grinding → degassing. This solution leverages professional equipment to achieve homogenized, highly dispersed slurry preparation.

Solid Oxide Fuel Cell Manufacturing Solution: Complete Process Flow and Technical Advantages

1. Pre-Mixing Stage: Initial Homogenization of Raw Materials

Raw materials – including nickel oxide (a key anode material), yttria-stabilized zirconia (electrolyte/electrode support material), organic additives (to improve slurry rheology and binding properties), and solvent – are fed into a pre-mixing equipment (such as the ZYE Pre-Mixer) according to the formulation ratio. Mechanical stirring achieves initial dispersion and mixing, laying the groundwork for subsequent fine grinding. The core objective of this stage is to ensure the uniform distribution of all raw materials on a macro-level, preventing issues in subsequent processes caused by agglomeration or stratification.

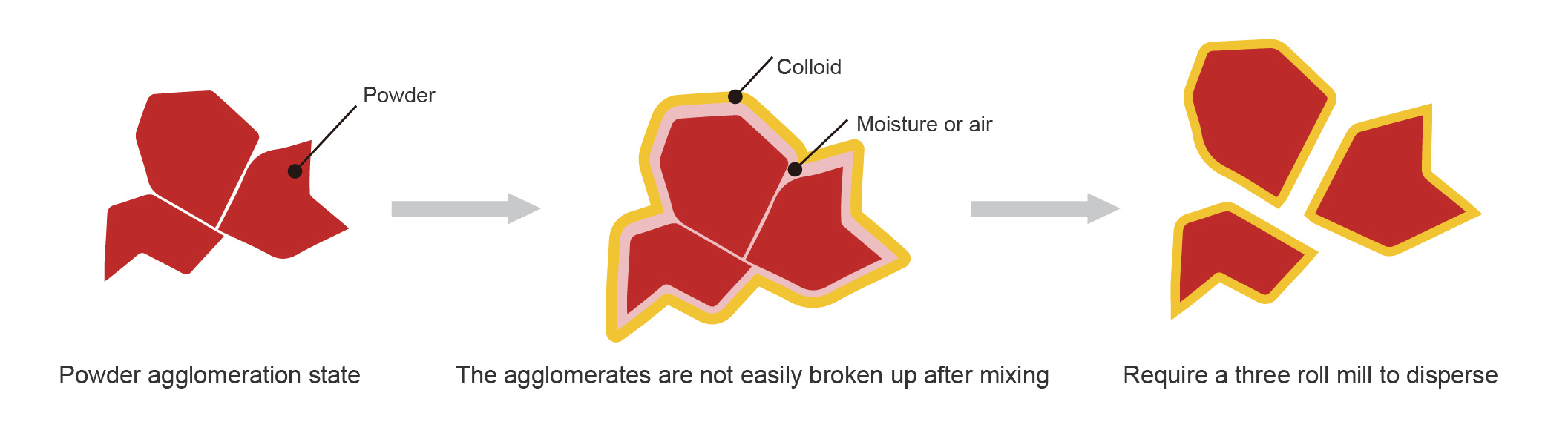

2. Fine Grinding Stage: Solving Powder Agglomeration

The pre-mixed slurry undergoes fine grinding and dispersion using a ZYE Three Roll Mill. The mill utilizes high-intensity shear and compressive forces to thoroughly break down powder agglomerates within the electrode slurry, resulting in a more uniform particle size distribution and significantly improved dispersion. This step directly determines the slurry's microstructure, thereby influencing critical SOFC electrode performance metrics such as electrical conductivity and porosity. Post-treatment, the slurry's dispersion quality is qualitatively enhanced, ensuring highly efficient electrochemical reactions within the cell.

Schematic diagram of material dispersion

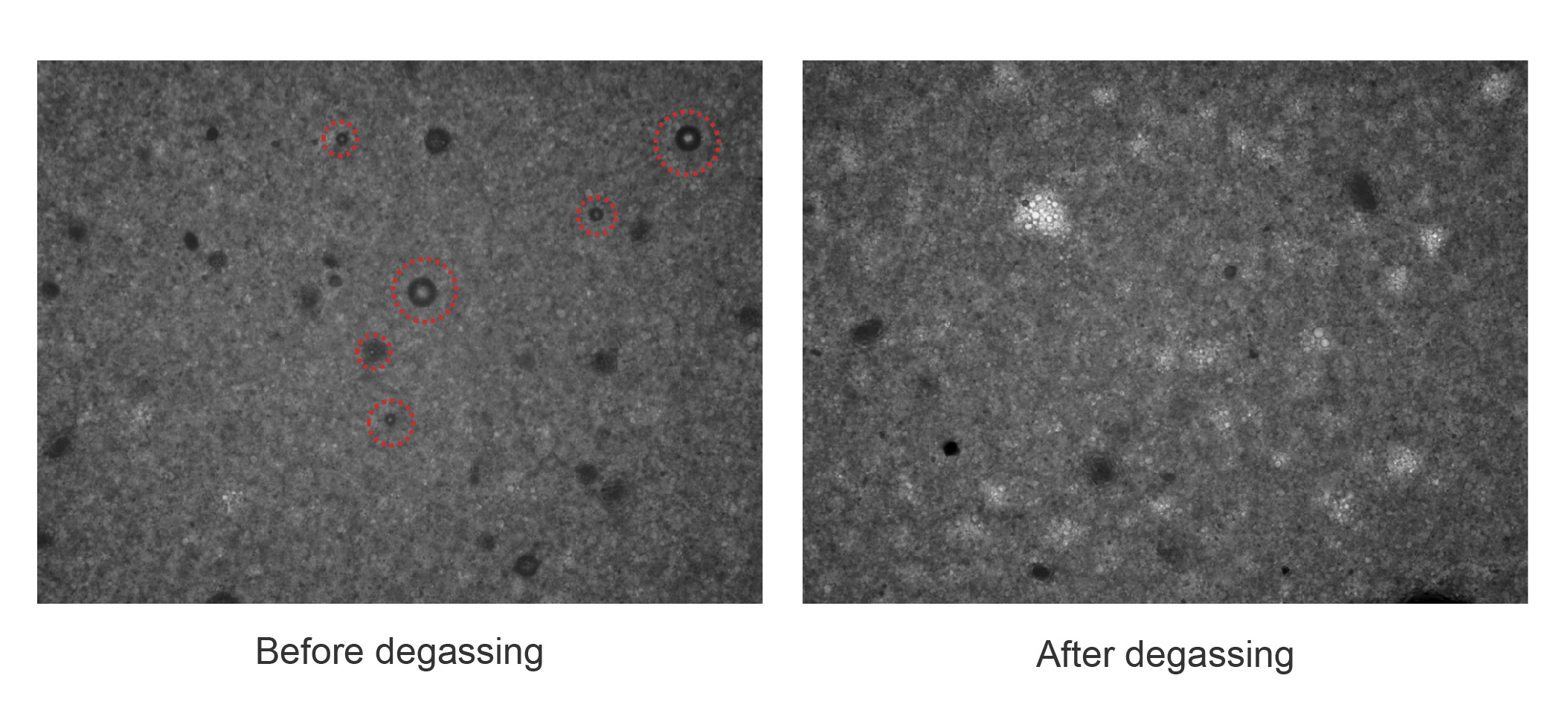

3. Degassing Stage: Ensuring Slurry Density and Uniformity

The ground slurry tends to entrap air, forming bubbles. These bubbles can lead to pores in the electrode layer and poor interfacial adhesion. Employing a ZYE vacuum planetary mixer for the degassing process effectively removes these bubbles, bringing the slurry to a highly homogeneous and dense state. The degassed slurry enables the formation of a structurally uniform electrode layer in subsequent coating and sintering processes, significantly improving the performance stability and service life of the SOFC.

This manufacturing solution, through precise control over the entire "pre-mixing → fine grinding → degassing" workflow for electrode slurry, addresses common industry challenges like powder agglomeration and residual bubbles at their root. It delivers the following core value:

Performance Enhancement: Produces electrode slurry with excellent dispersion and high uniformity, substantially improving key SOFC electrochemical performance metrics (e.g., power density, open-circuit voltage).

Process Stability: Standardized equipment and processes ensure consistency between production batches, providing crucial process assurance for the scaled manufacturing of SOFCs.

Cost Optimization: The efficient preparation process reduces raw material waste and the rate of subsequent defective products, indirectly lowering the industrialization costs of SOFCs.

Amid the ongoing wave of innovation in new energy battery technology, Solid Oxide Fuel Cells have emerged as a pivotal development direction in the energy sector due to their unique advantages. This preparation solution, with its refined and intelligent process approach, provides key technical support for breakthroughs in SOFC performance and their successful industrialization, powering the new energy battery industry towards a more efficient and sustainable future.