Unlocking New Value In Electronic Label Inks: Three Roll Mill Takes Center Stage

In today's era of rapid technological development, electronic tags have been widely used in logistics, retail, healthcare, and many other fields, becoming an indispensable part of our daily lives. As one of the core materials of electronic tags, the quality of electronic tag ink directly affects the performance and application of these tags. In the production process of electronic tag ink, the three roll mill plays a crucial role, earning it the title of the "master grinder" behind the scenes.

Electronic tag ink is not an ordinary ink; it needs to possess multiple special properties. First, it must have good electrical conductivity to ensure accurate transmission of electronic signals, which is crucial for reading and writing data on electronic tags. Second, the ink requires extremely fine particle size, with uniformly small particles. Coarse particles can not only affect the uniformity of the ink coating on the electronic tag substrate but also potentially cause unstable connections between electronic components, thereby impacting the overall performance of the electronic tag, such as reducing reading accuracy and stability.

In addition, electronic tags may be used in various complex environments, so the ink must also have excellent weather resistance, corrosion resistance, and abrasion resistance, ensuring long-term performance under different temperatures, humidity, and exposure to chemicals.

As the most effective equipment for grinding and dispersing medium- and high-viscosity materials, the three roll mill can utilize the strong shear forces generated by different rotation directions and speed differences to perform fine grinding and dispersion of materials.

Compared with other dispersing and grinding equipment, ZYE's three roll mill demonstrates numerous irreplaceable advantages in the production of electronic tag ink:

1.High Shear Force: The higher the viscosity of the material, the more difficult it is to disperse. Ordinary mixing and dispersing equipment cannot provide enough energy to break these strong agglomerates. ZYE three roll mills can deliver the tremendous energy required to overcome these cohesive forces, achieving ultra-fine dispersion and uniform particle distribution.

2.Progressive Grinding and Refinement: ZYE three roll mills allow precise control of the roller gap down to 1 μm. Through progressive gap adjustments, the mill not only breaks up particle agglomerates but also ensures that the dispersed phase is not damaged within the continuous phase, achieving molecular-level uniform distribution. This results in excellent gloss, color development, and stability.

3.Strong Adaptability for High-Viscosity Materials: Because ZYE three roll mills do not rely on reducing viscosity to operate, many formulations require little to no additional solvents. This enables the production of high-solid, low-VOC products, making the process more environmentally friendly.

4.A domestic electronic materials company faced a critical technical challenge while developing high-performance conductive ink for electronic tags: the solid components of the ink needed to be strictly controlled to below 2 μm. Previously, the client tried various dispersing equipment and other types of three roll mills for multiple process trials but could not overcome the technical bottleneck due to insufficient shear force or inadequate precision.

To address this challenge, we conducted ink dispersion trials using the ZYE ZYTR-80E Plus three roll mill. This machine is equipped with three sets of high-precision zirconia rollers, employs a progressive speed ratio of 1:3:9, and features a micron-level gap control system with precision up to 1 μm. It generates a stable and controllable high-intensity laminar shear field, effectively breaking up particle agglomerates and precisely constructing a single-dispersion system.

While effectively breaking agglomerates, the ZYTR-80E Plus perfectly preserves the intrinsic morphology and properties of functional materials, ultimately achieving the particle size control target and solving the client's technical problem.

Dispersion Solutions For Electronic Inks

Experimental Material: Electronic Label Ink

Experimental Location: UV Laboratory No. 2

Experimental Equipment: ZYTR-80E Plus Three Roll Mill + Fineness of Grind Gauge + Microscope

Experimental Objective:To achieve more uniform dispersion of the material through three roll milling and to reduce the particle fineness to below 2μm.

Experimental Procedure

01 Initial Measurement

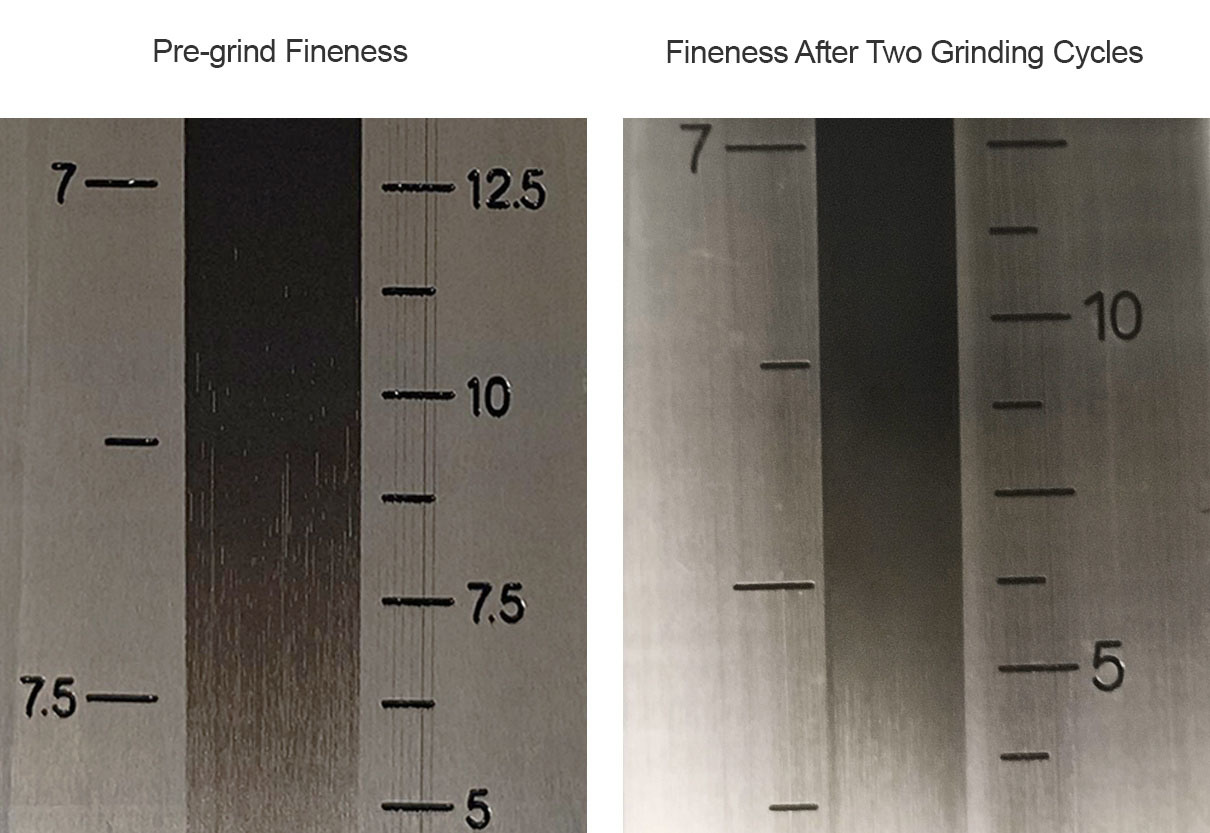

A small amount of the material was taken and tested with a scraper fineness gauge. The initial measurement showed a fineness of ≤12.5μm.

The material was then processed twice using the ZYTR-80E Plus Three Roll Mill in gap mode for pre-dispersion. After processing, the scraper fineness gauge measurement indicated a fineness of <5μm, as shown in the figure below:

02 Discharge Measurement

The material was processed using the ZYTR-80E Plus Three Roll Mill in pressure mode for grinding and dispersion.

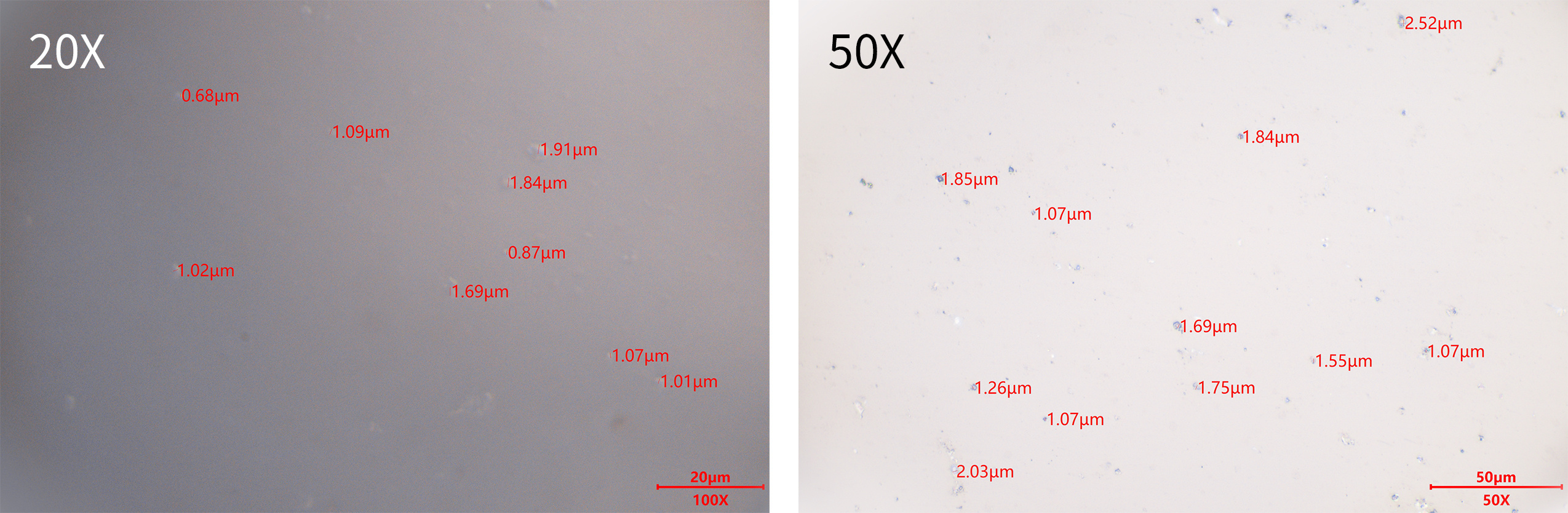

Subsequent testing was carried out under a microscope at 20x and 50x magnification.

The results indicated that most particle sizes were reduced to <2μm, as shown in the figures below:

03 Results Analysis

After premixing, measurements with the grind gauge revealed agglomerates of approximately 12.5 μm.

Following dispersion with the three roll mill, microscopic observation confirmed that the particle size within the system had been reduced to below 2 μm, representing a reduction of 84%.

This demonstrates the significant de-agglomeration capability of the three roll mill, with a marked improvement in both particle dispersion and uniformity after grinding.

With the continuous advancement of IoT technologies, the application scenarios for electronic tags are expanding, and the requirements for their performance and quality are becoming increasingly stringent.

Electronic tag inks produced with the ZYE Three Roll Mill enable higher resolution and clearer display quality in electronic tags.

In logistics and warehousing, this ensures faster and more accurate identification of goods.

In the retail sector, it enhances inventory management efficiency and improves consumer shopping experiences.

Meanwhile, excellent conductivity and stability ensure that electronic tags can operate reliably even in complex environments, reducing data transmission errors and improving overall system reliability.

This not only meets the current market demand for high-performance electronic tags but also lays a solid foundation for their adoption in emerging application fields.