In-depth Analysis Of The Temperature Control For Thermal Gel

In recent years, with the rapid development of electronic information technology, the heat generated by each component during work has increased sharply. And too high temperature will affect the operating efficiency and service life of components, and even lead to the failure of components, so more efficient heat transfer media is needed. Among many thermal conductive materials, thermal conductive silicone is the most widely used material. But it is difficult to cover uneven places, and the thickness selection is limited, and the thermal resistance is larger than that of liquid silicone. Thermal gel can solve these problems.

Thermal conductive gel , also known as thermal conductivity paste or thermal silica gel , is a kind of viscous substance with high thermal conductivity and is widely used in thermal management systems of electronic equipment. For example, high-performance components such as processors and graphics cards in computers and servers, as well as base stations and other high-power devices in communication equipment. By filling the tiny gap between the electronic components and the radiator, it eliminates the air, a poor conductor of heat, forming a continuous thermal conduction channel, which significantly improves the efficiency of heat conduction from the heat source to the radiator.

Thermal gel is usually made of silicone resin, crosslinking agent and thermal conductive filler by stirring, mixing, encapsulation and curing. It comes in one component and two components. Among them, the two-component thermal gel is divided into component A and component B. Component A is composed of silicone resin, crosslinking agent and filler, and component B is composed of silicone resin, catalyst and filler. The two are mixed and cured to form a heat-conducting gel.

Advantages of thermal gel:

1.thermal gel has the characteristics of low stress, high compression modulus. It can be compressed into a variety of shapes, the lowest can be compressed to 100-200μm. In addition, the shape after extrusion curing will not change, nor will it flow and collapse, which can realize automatic production;

2.good contact with the assembly of electronic products, showing low contact thermal resistance and good electrical insulation characteristics;

3.the physical properties are not affected by temperature, can be used in a wide temperature range (-40℃ ~ +200℃).

Thermal gel solutions:

Thermal gel has excellent heat transfer performance, and the mixing and defoaming of thermal gel is a key factor to ensure its performance. If the two components of the thermal gel cannot be completely dispersed, such as the powder remaining at the bottom of the container, it will affect the mixing ratio of AB glue per unit volume and affect the performance of all aspects of the product. Thermal gel is mainly a combination of oil and powder. When the oil and powder do not combine well, it is easy to layer (separate out). The powder solid content of thermal gel is generally high, and the dispersion process of high solid content materials often generates large heat, which makes the material viscosity different from the normal state, prolongs the detection time, and reduces the formula development efficiency.

In order to solve the dispersion problem of thermal gel. First of all, choose the appropriate defoaming machine. Different defoaming machines have different characteristics and functions. When choosing a defoaming machine, it is necessary to determine according to the nature of the thermal gel and the degree of degassing required. Different defoaming mixing processes and equipment directly affect the physical and chemical properties of materials, which determine the specific application of materials in industry.

Then choosing a defoaming machine that meets the needs of the application is particularly critical. ZYE Technology has developed and launched ZYMC-350VS - air-cooled vacuum mixing defoaming machine (also known as non-interventional material homogenizer). ZYMC-350VS air-cooled model is a combination of revolution, rotation, vacuum debubbling, cooling as one of the mixed debubbling machine, at the same time with temperature control, mixing, debubbling, temperature measurement functions, to meet the different viscosity of the material, without destroying the material, but also improve the material performance, to meet the application needs of higher standards.

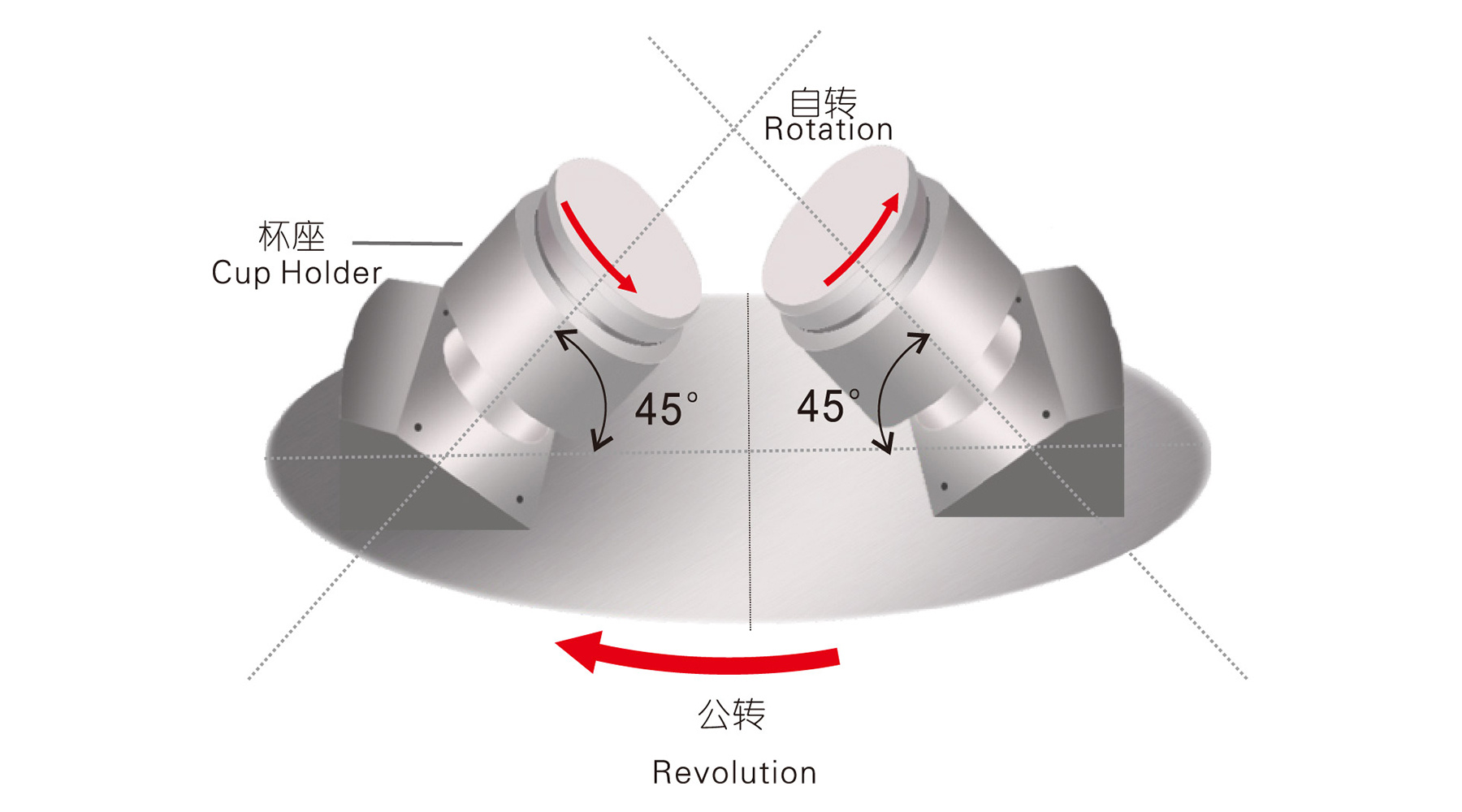

The working principle of mixing defoaming machine:

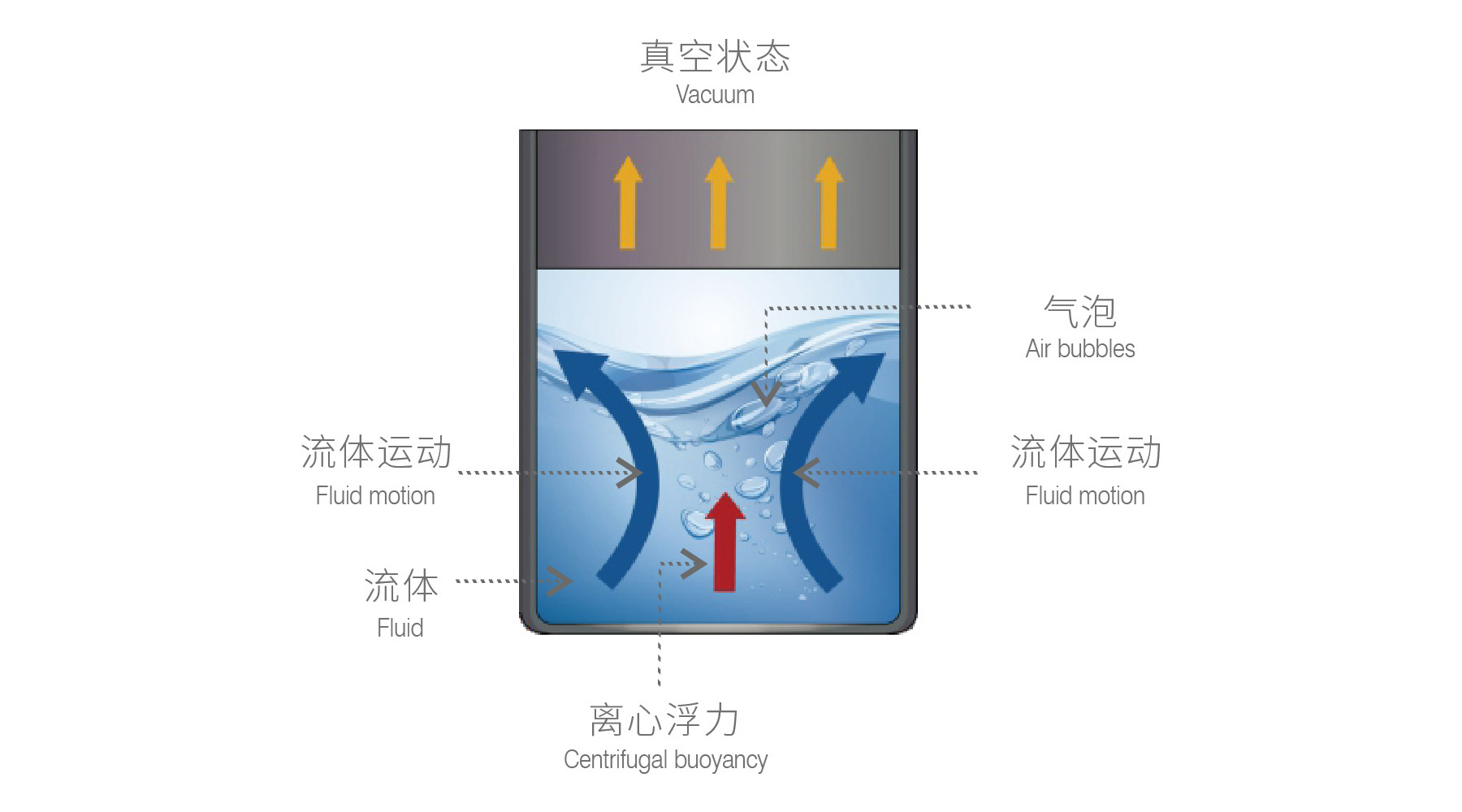

Revolution: The carrier rotates around the central axis at a high speed inside the equipment cavity, using the centrifugal force generated to make the material inside the carrier move along the vector direction, squeeze down and discharge the bubbles.

Rotation: the carrier itself rotates at a high speed, and under the influence of the force of revolution at the same time, the material is formed by the resultant force into a whirlpool flow and is fully mixed.

Defoaming: Through a strong centrifugal force, the bubbles inside the material are pressed to the surface, and supplemented by a high vacuum, the bubbles inside the material can be completely removed.

Cooling: Cold air is continuously injected into the chamber of the machine, and the heat generated by the friction of the material is taken away in time, so as to control the mixing temperature, improve the efficiency and stability of the material mixing, and extend the operable time of materials such as adhesives.

Experimental case:

Experimental equipment: ZYMC-350VS ZYMC-350VS air-cooled model

Experimental material: thermal gel

Experimental Objective: To reduce the temperature rise during mixing of thermal gel by mixing defoaming machine

Experimental Procedures:

1. Prepare two sets of the same material. The liquid component and the solid component of the material are respectively put into two cups of the same size and material in the same proportion.

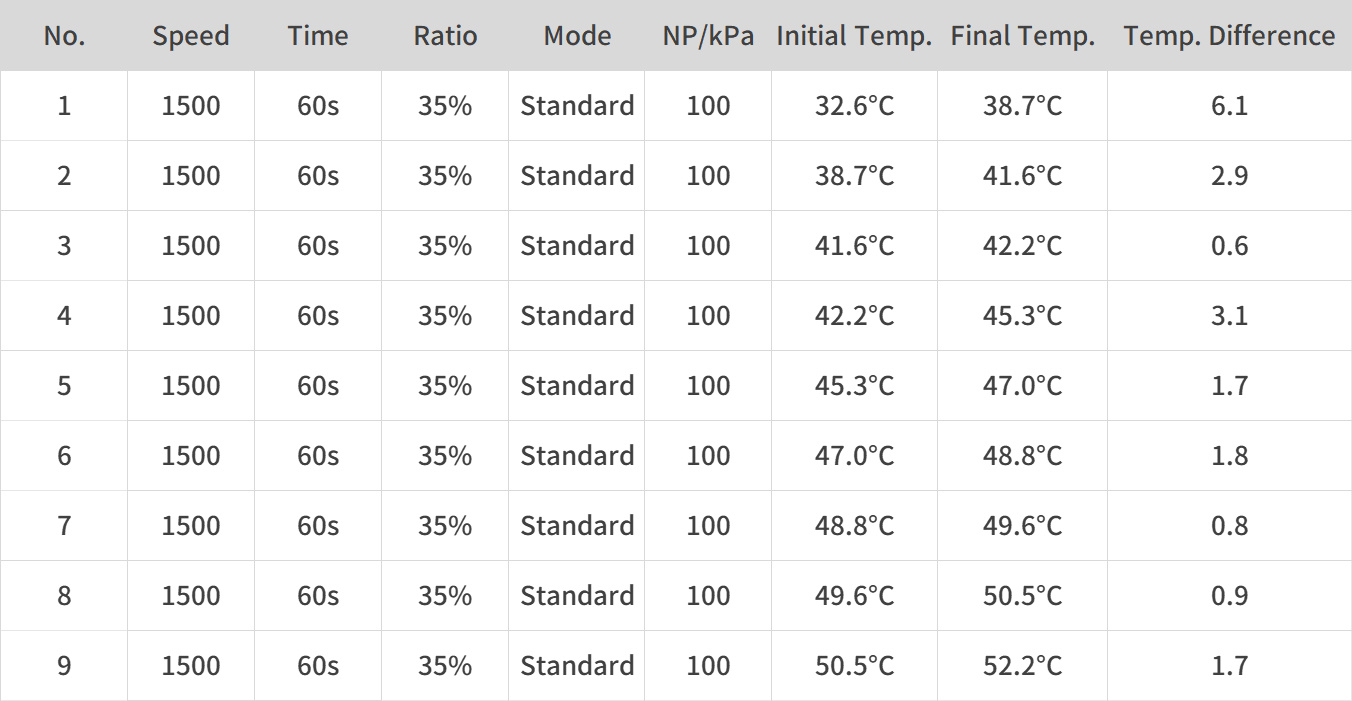

2. The ZYMC-350VS standard model was used to mix one of the materials, and the medium and low speed was continuously mixed for nine times (1min each time). After the material was mixed 1-2 times, there was no dry powder and the whole was uniform, but there was obvious heat after mixing, and the temperature reached more than 50℃ after mixing nine times.

3. The ZYMC-350VS air-cooled model is used to mix another material with the same parameters for nine times. After the material is mixed 1-2 times, there is no dry powder and the whole is uniform. When the material is mixed for three times, the material temperature gradually stabilizes at about 40 degrees and does not continue to rise.

Experimental picture:

Comparison before and after mixing by standard model

Comparison before and after mixing by air-cooled model

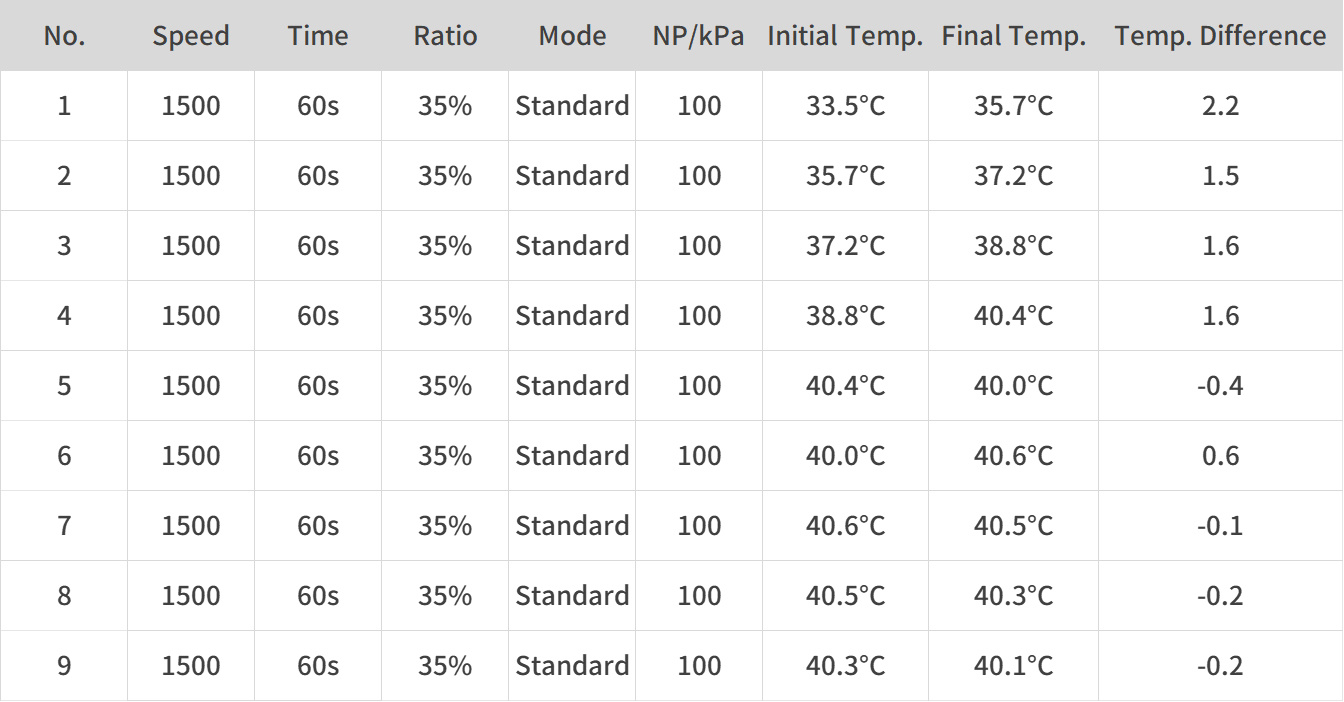

Experimental data:

Standard Model

Air-cooled model

Result Analysis:

1. Standard model and air-cooled model can quickly mix the material evenly;

2. During the first four times of mixing, the temperature rise difference between air-cooled model and standard model is small (temperature difference of about 5 degrees). With the increase of mixing times, the temperature control effect of air-cooled model is gradually obvious, and the material in the air-cooled group is gradually stabilized at about 40 degrees;

3. After mixing nine times, air-cooled temperature control is about 12 degrees lower than the temperature rise of standard model, and the air-cooled temperature control effect is obvious.

Recent Applications