Breakthrough In Dispersion Of Medium Paste! ZYE Three Roll Mill Enables Ultra-Fine Dispersion Of Medium Paste To 12μm

In the field of electronic component manufacturing, the dispersion fineness of dielectric paste directly determines product performance. With the surge in demand for high-frequency dielectric substrates in 5G communication equipment, many companies face technical bottlenecks when developing new high-frequency dielectric pastes. Traditional dispersion equipment has been unable to control paste fineness below 15μm, severely affecting dielectric loss and signal transmission stability. This article reveals how ZYE Three Roll Mill overcomes this industry challenge through innovative technology.

Dielectric paste is a type of electronic paste, functionally classified into resistor paste, conductor paste, and dielectric paste. It is a paste-like material composed of glass powder, pigments, and organic carriers. As a key material for core components such as multilayer ceramic capacitors (MLCC) and LTCC substrates, the dispersion quality of dielectric paste directly affects:

① High-frequency dielectric loss (for every 5μm reduction in fineness, loss value can improve by 15%)

② Uniformity of tape casting

③ Degree of sintering densification

Traditional equipment struggles to break the 15μm technical barrier from an initial fineness of 50μm due to insufficient shear force and excessive temperature rise.

A high-end electronic materials company in Shandong faced a critical technical challenge during the development of high-performance dielectric paste — the particle size must be strictly controlled below 15μm. Traditional dispersion equipment, limited by inadequate shear force and temperature control precision, repeatedly failed to overcome this technical bottleneck despite multiple process validations.

To address this challenge, we employed the ZYTR-80E Plus three-roll mill to disperse the dielectric paste. This equipment utilizes the speed differential of three high-precision zirconia rollers (1:3:9) and micron-level gap control (accuracy: 1μm) to generate a controllable laminar shear field. This enables precise deagglomeration of particle clusters and the formation of a monodisperse system, perfectly preserving the intrinsic morphological characteristics of the material.

Dielectric Paste Dispersion Solution

Client: A Shandong Electronics Company

Test Material: Dielectric Paste

Test Equipment: ZYTR-80E Plus Three Roll Mill + Fineness Gauge with Scraper

Test Objective: Achieve more uniform dispersion of the material and reduce the fineness to below 15μm through three-roll mill grinding.

Experiment Steps

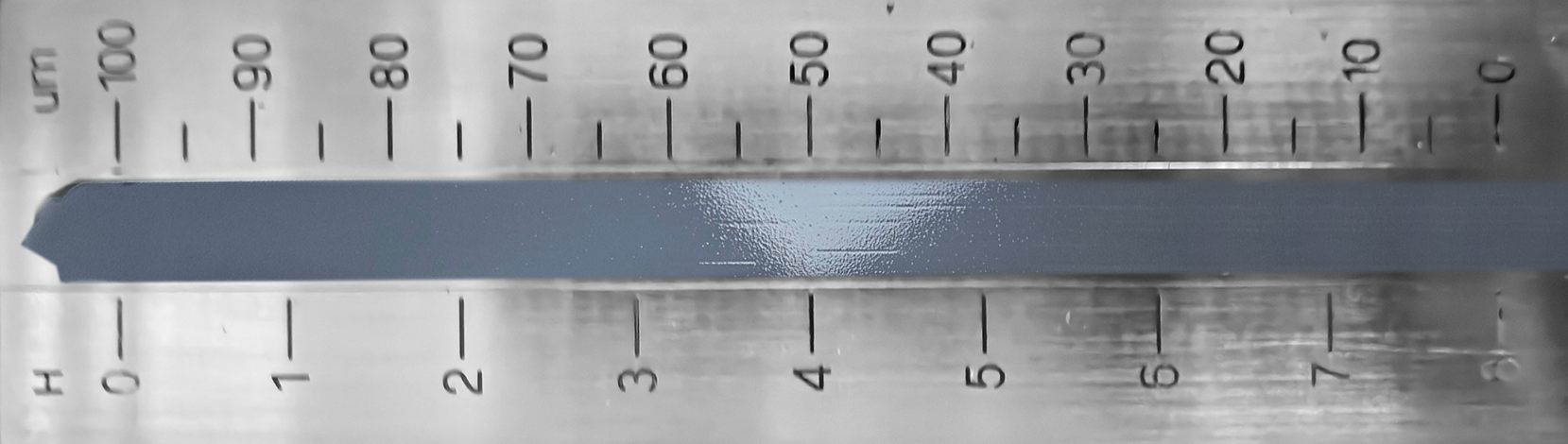

1.Initial Measurement

Take a small amount of material and measure the initial fineness using the scraper-type fineness gauge. The gauge indicates a fineness below 50μm, as shown in the figure below:

2.Three-Stage Dispersion Process

Using the ZYTR-80E Plus three-roll mill, the paste undergoes a three-stage dispersion and homogenization process to ensure particle size is stably controlled below 15μm, significantly improving the paste's gloss and rheological properties.

① Coarse Roll Stage: Roll gap 50–25μm

② Secondary Fine Grinding: Roll gap 30–15μm

③ Final Homogenization: Roll gap 10–5μm

During operation, the three-roll mill discharges uniformly without leakage, as shown in the figure below:

Dielectric Paste Before and After Grinding Effects

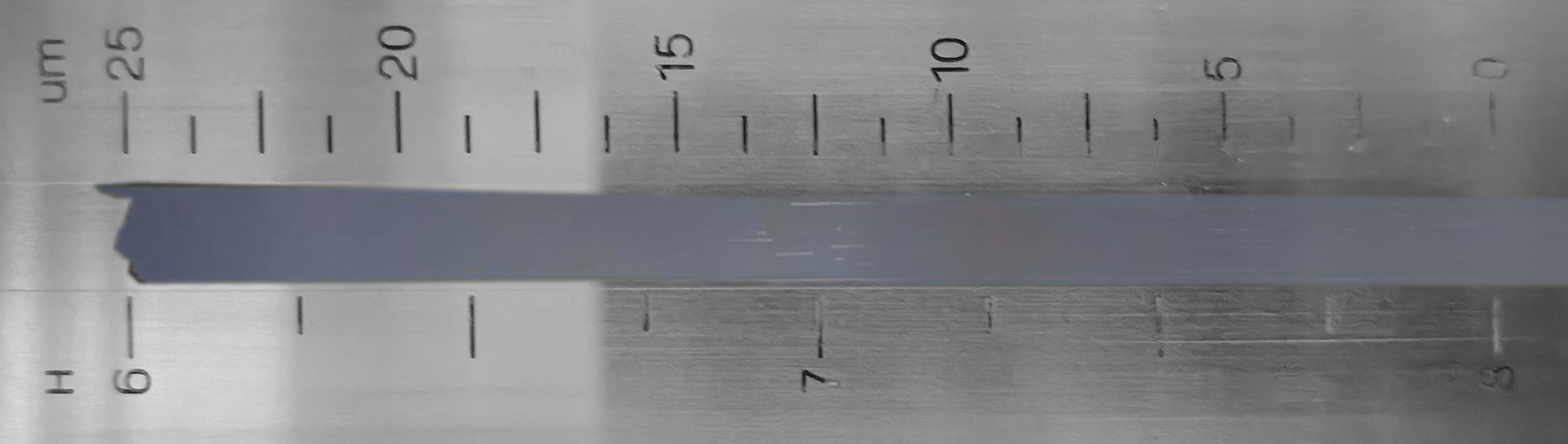

3.Discharge Inspection

A small amount of the milled material was taken for re-evaluation using a scraper fineness gauge. The fineness reading showed 12μm, as illustrated in the image below:

4.Result Analysis

By using ZYE Technology's ZYTR-80E Plus three roll mill, and comparing the scraper fineness gauge results, the following can be concluded:

1.Fineness Breakthrough:The particle size was reduced from an initial 50μm to 12μm — a 76% reduction.

2.Process Advantages:

① Quantifiable Gap Adjustment: The gap setting is visual and precisely adjustable, making it easy to scale up from lab testing to mass production. This effectively resolves the common industry issue of "successful in lab trials, failed in scale-up."

② Significantly Improved Yield Rate: The process ensures more consistent and higher-quality output.

Currently, this technological breakthrough has been successfully applied in:

1.5G Base Station Dielectric Filter Pastes

– Dielectric constant consistency improved to ±0.15

2.Millimeter-Wave Radar Substrate Materials

– Dielectric loss reduced to 0.0008 @ 28GHz

3.High-Density Integrated Circuit Packaging Dielectrics

– Line width precision improved to the 10μm level

ZYE's three roll mills are continuously empowering the electronic paste industry,and have been widely applied across adhesives, inks and coatings, electronics, new energy, nanomaterials, pharmaceuticals, cosmetics, and other fields.A full range of solutions has now been developed, from laboratory-scale to industrial-grade systems (with processing capacity up to 450L/h),providing high-precision dispersion support for advanced electronics manufacturing.