Fineness of Tungsten Slurry Improved by 65% — Three Roll Mill Reduces Particle Size from 20 μm to 7 μm

The slurry is composed of three main components: tungsten powder, an inorganic binder phase, and an organic carrier. Among them, tungsten powder serves as the functional phase, offering excellent thermal and electrical conductivity. It features a low coefficient of thermal expansion, which can be precisely tuned to match alumina ceramic substrates. This matching helps prevent stress during the metallization process, laying the foundation for effective hermetic sealing.

Key Commercial Value of Tungsten Slurry:

1. Electronics and Information Industry

Tungsten slurry is widely used in the manufacturing of electronic components such as logic chips, DRAM, and 3D NAND. It plays a critical role in forming electrodes and circuit traces, enabling high-precision, high-performance circuit patterns. This meets the growing demands for high integration, speed, density, reliability, and miniaturization in modern electronic devices.

For example, in multilayer alumina ceramic circuit boards, tungsten slurry enables high-temperature co-firing compatibility, excellent adhesion, and exhibits key properties such as good flowability, thixotropy, high resolution, and low sheet resistance—all of which are essential for enhancing the overall performance of electronic products.

2.Aerospace Industry

Tungsten slurry is applied in the manufacturing of high-temperature components for aerospace engines, such as combustion chambers and nozzles. Its excellent high-temperature resistance and corrosion resistance ensure the reliability and stability of these parts under extreme conditions. This directly contributes to enhancing engine performance and extending service life, playing a critical role in reducing operational costs and improving flight safety.

3.Automotive Manufacturing

As the automotive industry evolves toward electrification, intelligence, and connectivity, tungsten slurry finds applications in the production of automotive electronic components such as power modules and sensors. It helps enhance vehicle performance and safety, while also enabling the miniaturization and lightweight design of automotive parts.

Impact of Particle Size on Material Performance

1. Influence on Electrical Properties:

Finer tungsten slurry helps reduce the resistivity of the material and improves its electrical conductivity. Smaller particles provide more contact points between tungsten grains, allowing smoother electron transmission. Therefore, for electronic components with high conductivity requirements, controlling the particle size of tungsten slurry is essential to meet electrical performance standards.

2. Influence on Sintering Performance:

If the particle size of tungsten slurry is too large, tungsten particles may not fully densify during sintering. This can lead to increased porosity and reduced density in the final material, thereby affecting mechanical properties such as strength and hardness. For example, in ceramic metallization processes, substandard tungsten slurry fineness can significantly reduce the yield of sintered ceramic substrates.

3. Influence on Mechanical Properties:

An appropriate particle size of tungsten slurry can improve the toughness and fatigue resistance of the material. When the particle size distribution is fine and uniform, internal stress concentration points are reduced. As a result, the material can better disperse external stress, enhancing its mechanical performance and reducing the likelihood of cracks and fractures.

4. Influence on Printing Performance:

In processes such as screen printing used for electronic component fabrication, the particle size of tungsten slurry directly affects the resolution and quality of printed lines. Finer and more uniformly distributed tungsten particles enable more precise printing patterns, resulting in clearer and sharper lines—crucial for manufacturing high-precision electronic circuits.

To address the above issues, we use the ZYTR-80E Plus three roll mill to uniformly disperse such materials. The ZYE three roll mill achieves grinding and dispersion through the shear force generated by the horizontal arrangement of three rollers—each rotating in different directions and at different speeds—while being pressed tightly against one another.

With ZYE’s precise roller gap control, the mill enables effective deagglomeration without damaging the surface morphology of the materials, ensuring uniform dispersion and preserving the material’s structural integrity.

Tungsten Slurry Dispersion Plan

Customer Name: (Confidential)

Experimental Equipment: ZYTR-80E Plus Three Roll Mill (Zirconia Rollers), Ceramic Metal Blades, Fineness Gauge

Material: Tungsten Paste

Objective: To achieve uniform dispersion of the material by milling with a three-roll mill.

Procedure:

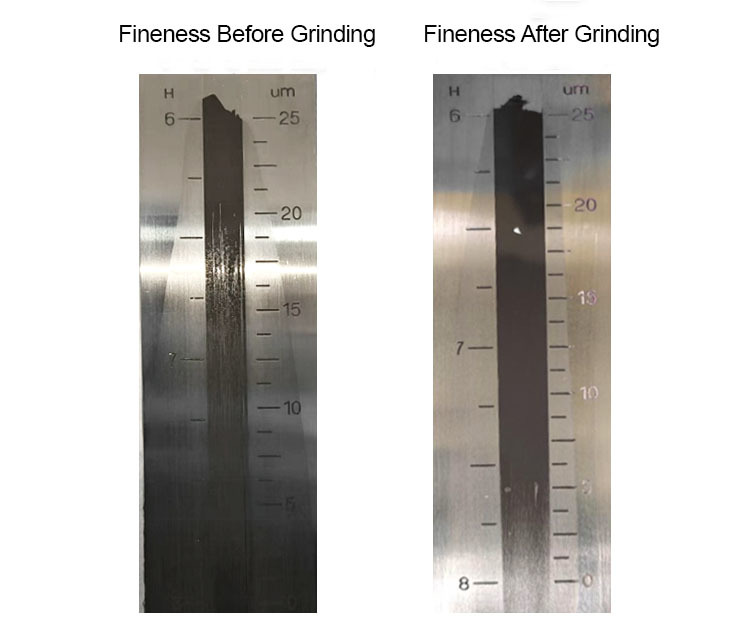

1.A small sample of the pre-mixed material was taken to measure its initial fineness using a fineness of grind gauge (grindometer).

2.The material was processed on a ZYTR-80E Plus Three-Roll Mill for a single pass, with the minimum output gap set to 1 micron. The resulting slurry was visibly finer and glossier, and the material discharged from the mill consistently during operation.

4.A small amount of the milled material was tested again with the grindometer. After milling, the grindometer reading showed that there were no particles larger than 7 microns present in the material.

Experimental data:

Result Analysis:

Observation of the pre-mixed material with a grindometer revealed the presence of agglomerates approximately 20 µm in size. After dispersion with the three-roll mill, however, microscopic observation showed that the particles within the system were all below 7 µm. This demonstrates the significant deagglomeration effect of the three-roll mill, which greatly improves the dispersion quality and uniformity of the final material.