Dispersion of single-walled carbon nanotube (SWCNT) conductive materials

Carbon nanotubes (CNTs), also known as buckytubes, are one-dimensional quantum materials formed by single or multiple layers of graphene rolled up at a certain helical angle around a central axis. They were first discovered by Sumio Iijima in 1991. The aspect ratio and carbon purity of CNTs are two core indicators that affect their conductivity and directly determine the product's performance. The smaller the diameter and the longer the length of a carbon nanotube, the better its electrical conductivity.

Carbon nanotubes can be viewed as rolled-up sheets of graphene. Therefore, based on the number of graphene layers, they can be classified as: Single-walled Carbon Nanotubes (SWCNTs) and Multi-walled Carbon Nanotubes (MWCNTs).

Commercial Advantages of Single-Walled Carbon Nanotubes (SWCNTs):

1. Simple Structure and Chemical Stability: During the formation of multi-walled carbon nanotubes (MWCNTs), the spaces between layers can easily become trapping sites for various defects. In contrast, SWCNTs possess a simpler, more uniform structure with fewer defects, resulting in greater chemical stability.

2. Low Dosage and Superior Conductivity: Due to their high aspect ratio (length-to-diameter), SWCNTs can form a three-dimensional conductive network at extremely low loading levels. Each SWCNT, consisting of a single layer of carbon atoms, can exhibit either metallic or semiconducting properties depending on its chirality (helical structure). Furthermore, their strong carbon-carbon bonds enable an exceptional current-carrying capacity, with a current density that can be over 1,000 times higher than that of metals like copper.

3. High Thermal Conductivity: The thermal conductivity per unit mass of SWCNTs is higher than that of MWCNTs. Additionally, both types of nanotubes can withstand high temperatures exceeding 750°C.

4. Enhanced Safety Performance: In pouch cells subjected to extensive high-temperature cycling (at 45°C), those containing SWCNTs show significantly less dendrite growth compared to cells using other conductive agents. This indicates a much lower risk of battery fire.

5. Improved Electrode Adhesion: The SWCNT network binds the active material particles together within the electrode, thereby increasing the inter-particle connection strength. This property is particularly crucial for silicon-based anodes, which are prone to pulverization and delamination during cycling.

With the rapid development of the lithium-ion battery industry, carbon nanotubes (CNTs) are increasingly demonstrating their vast application value, particularly as a conductive agent to enhance the electrical conductivity of both the cathode and anode.

With the rapid development of the lithium-ion battery industry, carbon nanotubes (CNTs) are increasingly demonstrating their vast application value, particularly as a conductive agent to enhance the electrical conductivity of both the cathode and anode.

Conductive agents are a critical auxiliary material in lithium-ion batteries, with their primary function being to improve the conductivity of the electrodes. A common issue with cathode active materials is their inherently poor electrical conductivity. This leads to high internal resistance within the electrode and an insufficient depth of discharge, which in turn results in low utilization of the active material and a larger residual capacity.

A conductive agent plays several vital roles:

① Enhancing Electron Transport: It increases the rate of electron transport within the electrode, thereby improving its overall electrical conductivity.

② Improving Ion Migration and Lifespan: It enhances the wetting of the electrode by the electrolyte, which accelerates the migration rate of lithium ions. This, in turn, improves the electrode's charge-discharge efficiency and extends its cycle life.

③ Maintaining the Conductive Network: When the active material in the cathode expands and contracts during charge-discharge cycles, the conductive agent maintains a robust electrical network, preserving conductivity that would otherwise be lost.

Currently, the mainstream conductive agents include carbon black, carbon nanotubes (CNTs), conductive graphite, Vapor-Grown Carbon Fiber (VGCF), and graphene.

Compared to traditional conductive agents, carbon nanotube (CNT) and graphene conductive agents are distinguished by their superior electrical conductivity and lower required dosage. Traditional agents like carbon black, conductive graphite, and VGCF form point-contact, surface-contact, or line-contact conductive networks among the active material particles. In contrast, carbon nanotubes and graphene are novel conductive materials that respectively establish line-contact and surface-contact networks.

Regarding dosage, the loading level of a conductive agent depends on the specific electrochemical system of the battery manufacturer, but it typically ranges from 1% to 3% of the total weight of the cathode or anode. In comparison, the required amount of CNT conductive agent powder is only 1/6 to 1/2 that of traditional agents.

As the market demand for high-performance batteries continues to rise, coupled with the application of new technologies like high-nickel cathodes and silicon-based anodes and their improving cost-effectiveness, the market penetration of carbon nanotubes (CNTs) is poised for rapid growth. CNTs can comprehensively enhance battery performance in terms of energy density, cycle life, and rate capability, making them highly aligned with downstream requirements.

1. Enhanced Energy Density: The required dosage of CNTs is only 1/6 to 1/2 that of traditional carbon black. This effectively reduces the overall mass of the electrode, thereby increasing the mass proportion of the active material and boosting the battery's energy density.

2. Extended Cycle Life: Due to their high aspect ratio, CNTs form a robust conductive network with the cathode material. This ensures strong connections between particles and prevents the material from cracking or detaching, which in turn extends the battery's cycle life.

3. Improved Fast-Charging Capability: The excellent electrical conductivity of CNTs reduces battery polarization and enhances its rate capability, thereby improving fast-charging performance.

4. Optimized High and Low-Temperature Performance: The high electrical conductivity of CNTs lowers the electrode's internal resistance and reduces heat generation. Furthermore, their superior thermal conductivity improves the battery's performance at both high and low temperatures and enhances its overall safety.

Single-walled carbon nanotubes (SWCNTs), as an emerging conductive material, hold broad application prospects. However, the quality of SWCNT dispersion is a critical factor that significantly impacts the final material's performance.

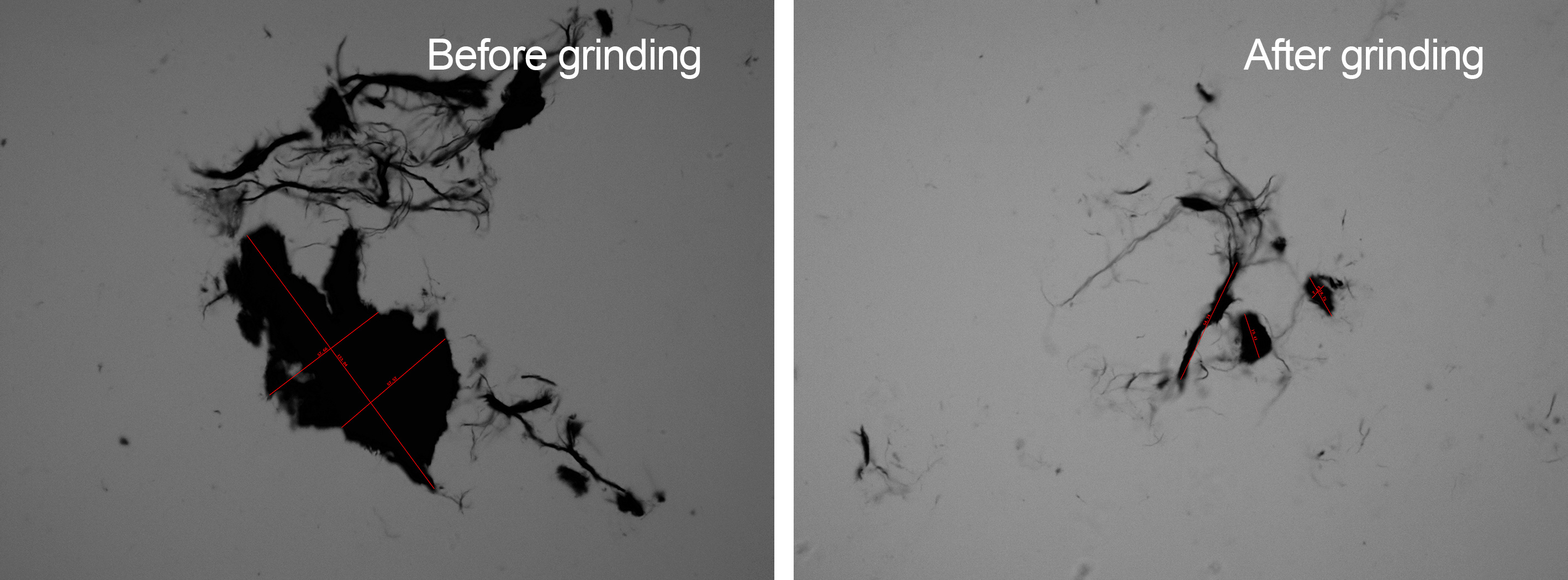

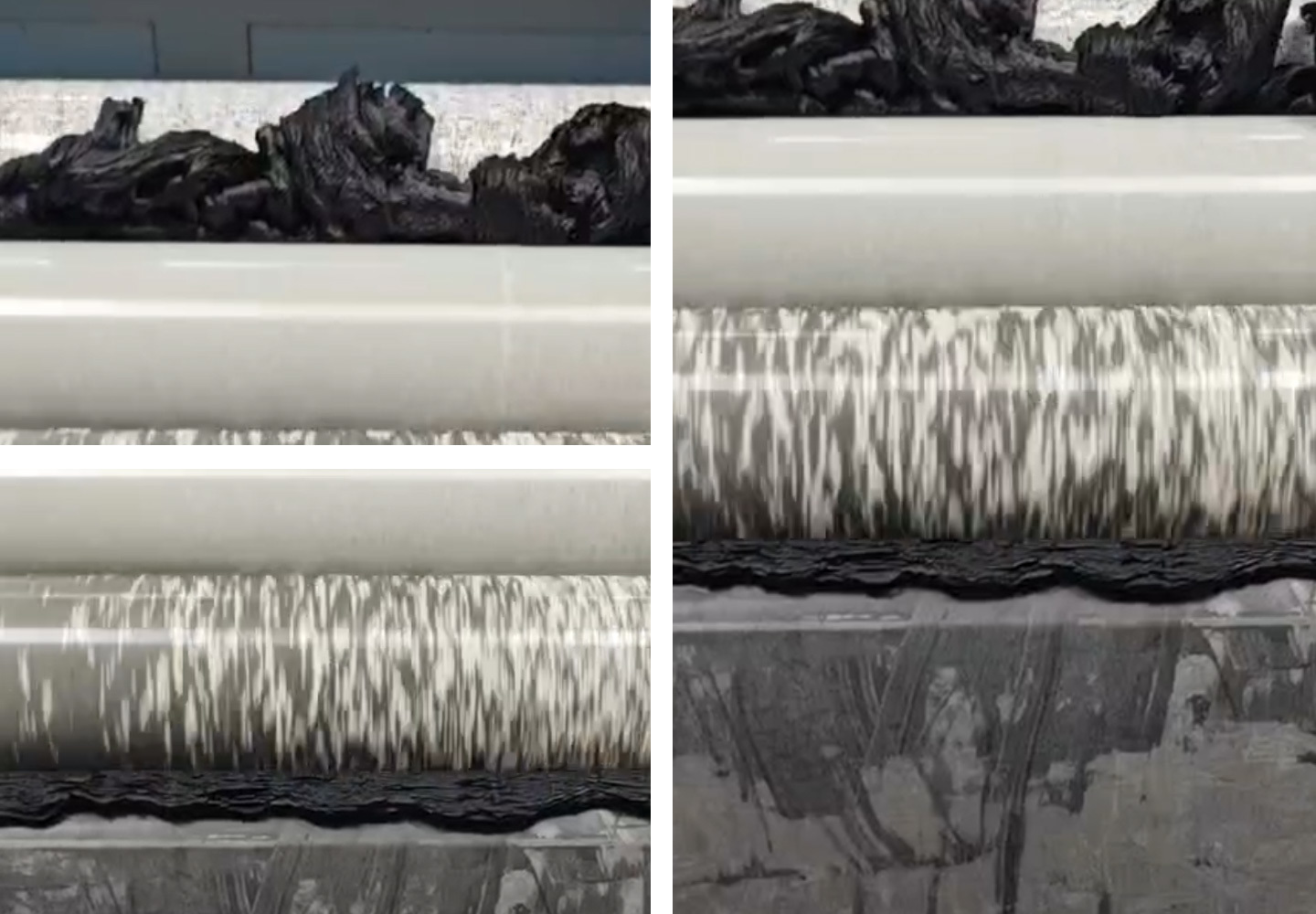

To address this challenge, we use the ZYTR-120E-450 Three-Roll Mill to achieve uniform dispersion of these materials. The ZYE three-roll mill leverages intense shear forces—generated by the compression, counter-rotation, and differential speeds of its three horizontal rollers—to achieve a grinding and dispersing effect. Moreover, its precise gap control enables effective deagglomeration of the material without damaging its surface morphology.

Case Study:

Client Name: SYHJ

Equipment Used: ZYTR-120E-450 Three-Roll Mill (with Zirconia rollers)、Cermet scraper blade、 Nikon Optical Microscope

Material(s) Used: Single-walled carbon nanotubes (SWCNTs)

Objective: To achieve a more uniform dispersion of the material by milling it with the three-roll mill.

Procedure:

1. The client's pre-mixed material was processed through the ZYTR-120E-450 three-roll mill for multiple passes.

2. After milling, a sample was taken, diluted with a solvent, and then observed under a microscope.

Experimental data:

The microscope magnified 400 times

Grinding photos:

Result analysis:

It can be seen from the microscope that the agglomeration of the material after grinding and dispersion by ZYTR-120E-450 three-roll mill is significantly reduced.