Comprehensive Analysis: The Effect Of Bubbles in High Viscosity Materials On Performance And The Secret Of Eliminating Bubbles

Many people may encounter the same problem when producing slurry, that is, there are too many bubbles in the material. If these bubbles are not removed in time, they will often cause serious consequences. This article takes you through the secret of eliminating bubbles for three different industries including adhesive, conductive silver paste and paint.

① Adhesive

Air bubbles in the adhesive can form voids or air pockets, affecting the adhesive's ability to form a continuous bond, thereby weakening the strength and durability of the bond. These air pockets can act as stress concentration points, and the force applied to the bond is unevenly distributed, making it more prone to failure. In addition, adhesives containing trapped air are more likely to weaken or fail prematurely when subjected to ambient pressures such as temperature changes or mechanical loads.

The presence of air bubbles can also cause inconsistent adhesive coverage. Because air occupies the space where the adhesive should be, the adhesive layer becomes uneven, thereby reducing the overall bonding surface area. This can lead to serious performance issues, especially in applications where uniform bonding is essential for structural stability or to ensure airtight and waterproof seals.

② Conductive silver paste

Bubbles will significantly reduce the conductivity of the silver paste, forming a barrier to current conduction. It is undoubtedly a major hidden danger to product quality and performance for applications such as circuit boards and solar cells that rely on high conductivity. Secondly, the bubbles will also destroy the smoothness of the silver paste, affecting the appearance of the product after coating or bonding, especially in the display, photovoltaic panels and other areas with strict appearance requirements. The existence of bubbles directly affects the market competitiveness of the product and user satisfaction. In addition, bubbles reduce the contact area between the silver paste and the substrate, resulting in reduced adhesion, which can lead to peeling or shedding of the silver paste layer, posing a potential risk for applications that require high adhesion, such as sensors and flexible electronics.

③ Paint

The presence of bubbles in the paint has a multi-faceted impact on the quality and beauty of the coating. The bubbles causes the surface of the coating to be uneven, and there will be raised bubbles or depressed traces, which will affect the overall beauty of the wall. In addition, bubbles weaken the adhesion between the paint and the wall, making the coating easy to peel or flake. Bubbles also reduce the density and uniformity of the coating, making it more susceptible to the external environment, such as ultraviolet light, moisture, etc., thus accelerating the aging and damage of the coating.

In terms of performance, bubbles reduce the covering ability of the coating, which may require multiple brushes to achieve the expected covering effect. In addition, the paint film formed by the coating with bubbles may not be dense enough, which will weaken the scrub resistance and water resistance of the wall. And the formation of bubbles in liquid slurry is a very complex problem. For the formation mechanism of bubbles in liquid slurry, the generally accepted view is cavitation phenomenon (cavitation), namely: Because the gas has a certain solubility, it usually exists in the form of bubble core in the liquid, and when the liquid flows through an area of very low absolute pressure in a very short time, the bubble core will quickly evaporate or free out. If you want to let these bubbles disappear naturally, you often need to wait for four stages: the bubble movement to the liquid surface; A liquid film is formed at the interface; Film rupture; Bubble separation from liquid level or bubble rupture.

In view of these troublesome bubble problems, ZYE Technology has developed a series of mixing and defoaming equipment to assist in solving these problem of slurry. ZYE vacuum defoaming machine combines revolution, rotation, vacuum defoaming and cooling. It also has the functions of temperature control, stirring, defoaming and temperature measurement, which can meet the requirements of materials with different viscosity without destroying materials. It can also improve material properties to meet the needs of higher standard applications.

Advantages of ZYE vacuum defoaming machine:

1. improve product quality: eliminate the bubbles in the glue, ensure that the product is more uniform and transparent, improve the quality and appearance of the product.

2. improve production efficiency: the efficient working principle of vacuum defoaming machine can complete the defoaming of a large amount in a short time, improve production efficiency.

3. reduce production costs: vacuum defoaming machine can reduce contact with materials, avoid waste.

4. wide application: various types of vacuum defoaming machine can be applied to different types of slurry with different viscosities.

Experimental cases:

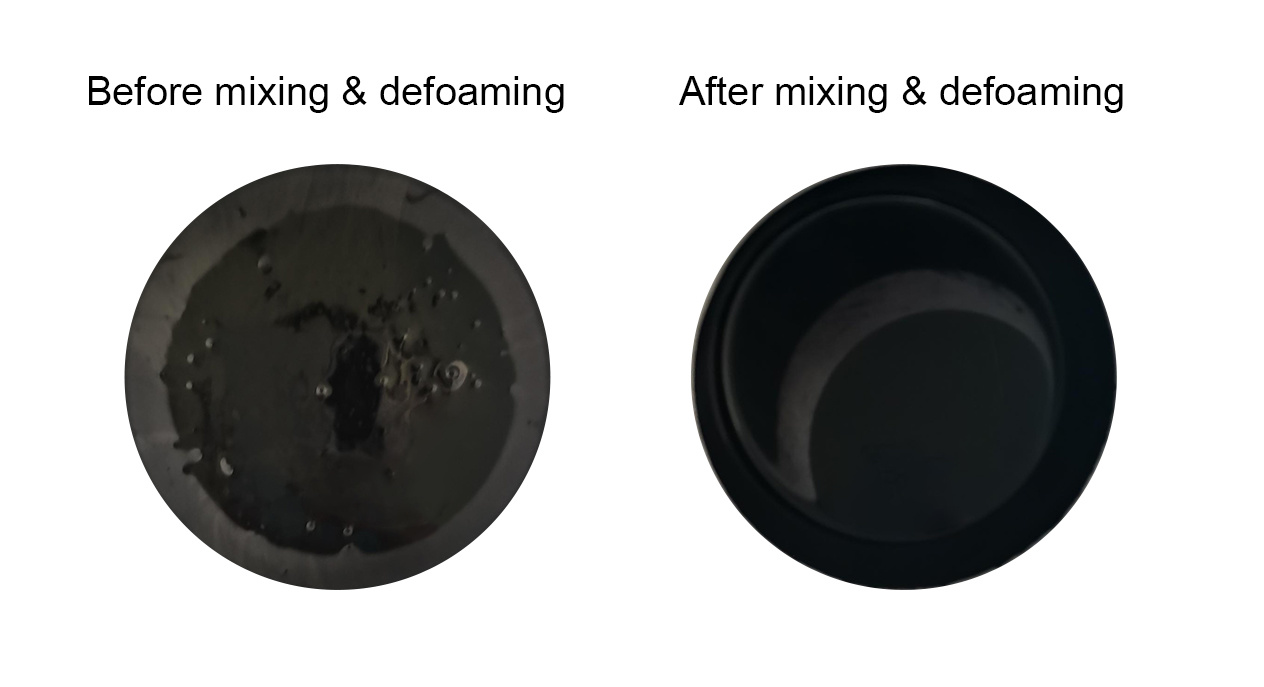

① Adhesive

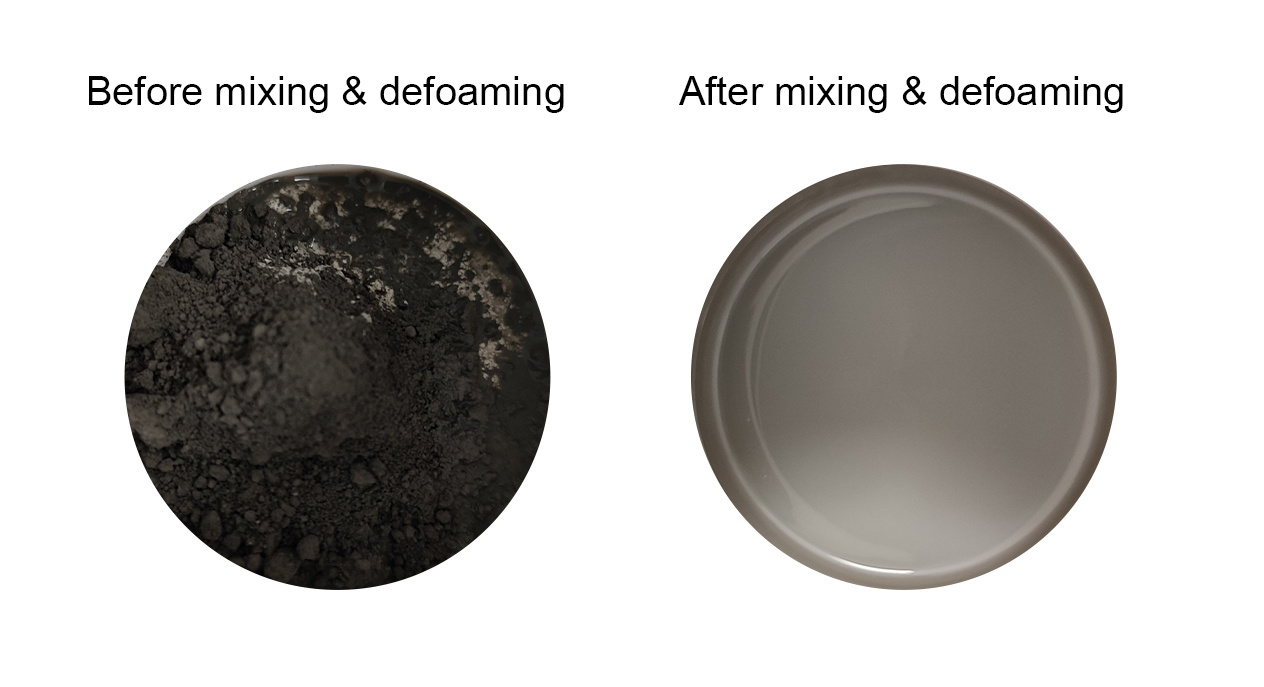

② Silver paste

③ Printing ink