Unlock the secrets to vibrant color and gloss in PVC—make your products more eye-catching and appealing

Polyvinyl chloride (commonly abbreviated as PVC) is the third most widely produced synthetic polymer in the world, following polyethylene and polypropylene. Approximately 40 million tons of PVC are manufactured annually. PVC is a polymer formed through a free radical polymerization process of vinyl chloride monomer (VCM), initiated by peroxides, azo compounds, or under the influence of light or heat. Both vinyl chloride homopolymers and vinyl chloride copolymers are collectively referred to as vinyl chloride resins.

PVC was once the most widely produced general-purpose plastic in the world, with extremely broad applications. Thanks to its flame resistance, chemical corrosion resistance, wear resistance, excellent electrical insulation, mechanical strength, and low cost, it developed rapidly and found widespread use in industries such as food packaging, toys, medical supplies, cosmetics, footwear, and plastic doors and windows. Today, PVC resins and their products rank second only to polyethylene in production volume, making PVC the world’s second most common general-purpose plastic.

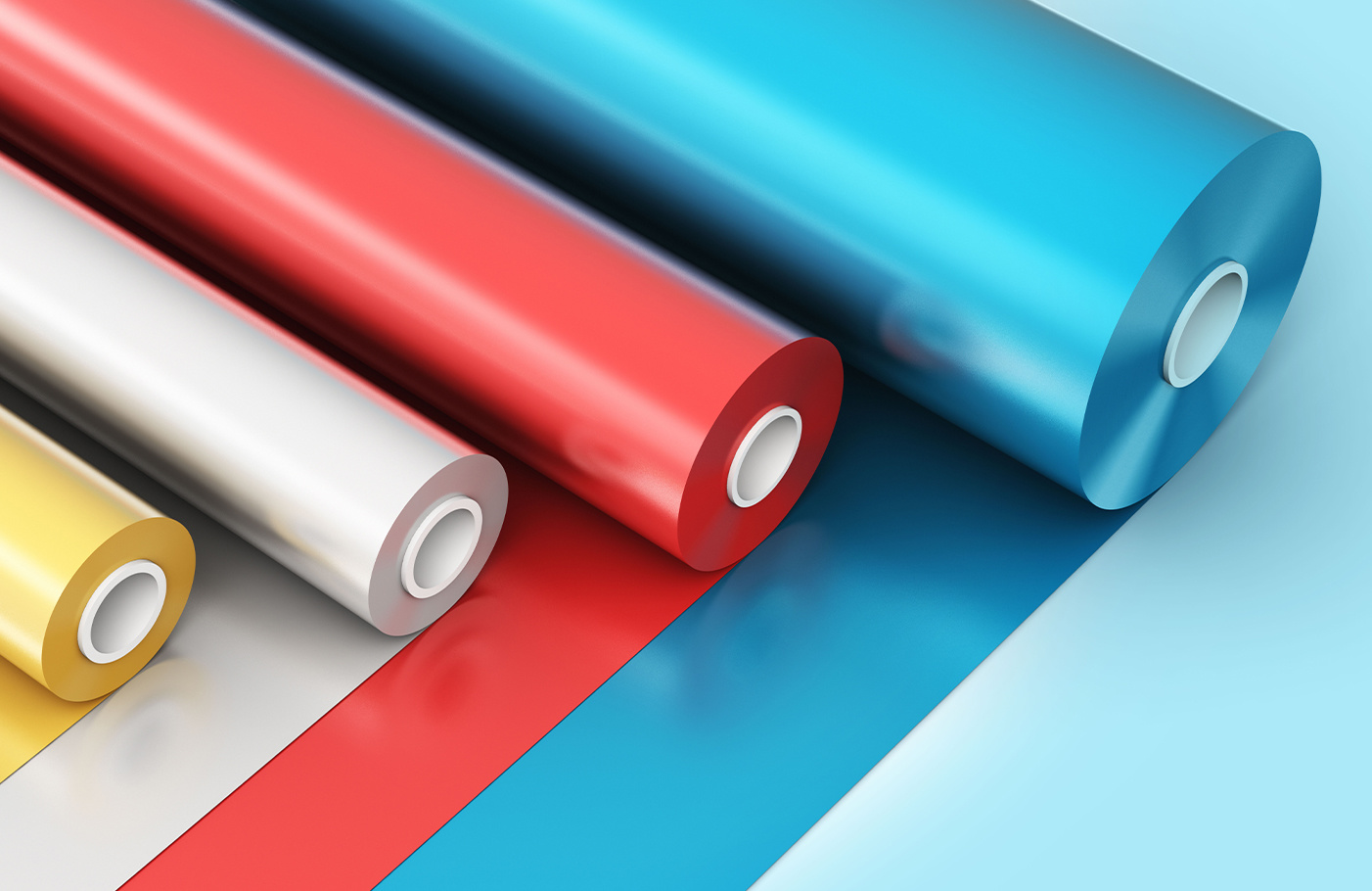

PVC film, as a printing medium for advertising graphics and decorative wallpapers, has been widely adopted. Produced primarily from PVC combined with additives such as plasticizers, stabilizers, and fillers, the resulting plastisol-coated PVC film is known for its vibrant colors, attractive appearance, low investment cost, quick results, ease of hanging and replacement, excellent comprehensive performance, affordability, and practicality. These advantages have earned it high praise across the industry and make it well-suited for the demands of the advertising and decoration sectors. As a result, its usage in these industries continues to grow.

However, inorganic filler particles in the gel tend to agglomerate into larger clusters, which causes diffuse reflection of light. This negatively affects the color reproduction and glossiness of PVC films. To address this issue, we use the ZYE hydraulic three roll mill for uniform dispersion of PVC plastisols.

Developed in-house by ZYE Technology, our hydraulic three roll mill offers multiple roller materials such as zirconia, alumina, silicon carbide, silicon nitride, and alloy steel—providing versatile solutions for dispersing various high-end, fine materials. The mill ensures effective dispersion without damaging the materials, thereby significantly enhancing the color vibrancy and glossiness of PVC films to meet higher application standards.

As one of the most efficient dispersion devices for high- to medium-viscosity materials, the three roll mill is capable of submicron-level fine dispersion and achieving an optimal particle size distribution.

Working Principle of the Hydraulic Three Roll Mill:

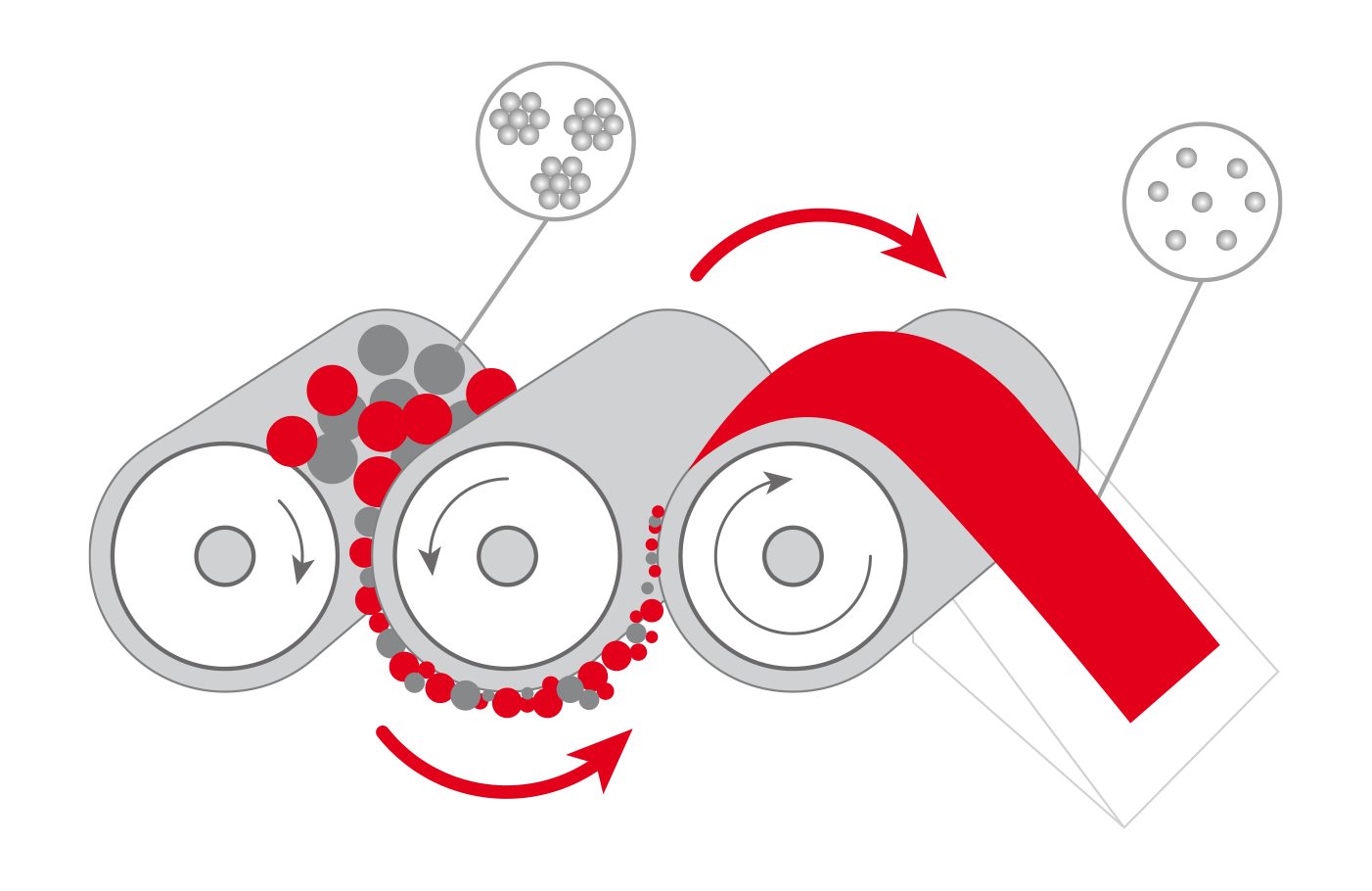

The three roll mill is a grinding and dispersing device composed of three rollers, motor and electrical control systems, and a set of transmission components. The three rollers are typically classified as the feed roller, the center roller, and the discharge roller.

In every three roll mill, the reduction of particle size and the dispersion of agglomerates are achieved through the combined effect of the pressing force between the rollers and the high shear force generated by the different rotational speeds of each roller, as illustrated below. Because all material is confined within the gap between the rollers, the particle size becomes precisely controllable and exhibits a narrow distribution. By adjusting the roller gap, particle sizes can be easily and accurately processed to the micron level—something that is significantly more difficult to achieve with other methods.

Dispersion Process for PVC Plastisol:

Customer Name: TLDZ

Experimental Equipment: ZYE Manual Hydraulic Three Roll Mill, Scraper Fineness Gauge

Experimental Material: PVC Plastisol

Objective: To achieve a more uniform dispersion of the material using the ZYE hydraulic three roll mill

Experimental Procedure:

1. A small amount of the initial material was taken and tested using a scraper fineness gauge. The reading showed that the initial particle size was greater than 100 μm.

2. The PVC plastisol was then processed using the manual hydraulic three roll mill. During the grinding process, the discharge was uniform with no leakage observed.

3. After grinding, another small sample of the material was tested again using the scraper fineness gauge. The result showed that the particle size had been reduced to approximately 20–30 μm.

Grinding photos:

Result Analysis:

The initial material, when tested using the scraper fineness gauge, showed significant agglomeration with particle sizes exceeding 100 μm. After dispersion using the three roll mill, subsequent testing revealed that the internal particle size had been reduced to below 30 μm. The three roll mill demonstrated a clear deagglomeration and dispersion effect, significantly improving the material’s uniformity and overall dispersion quality.

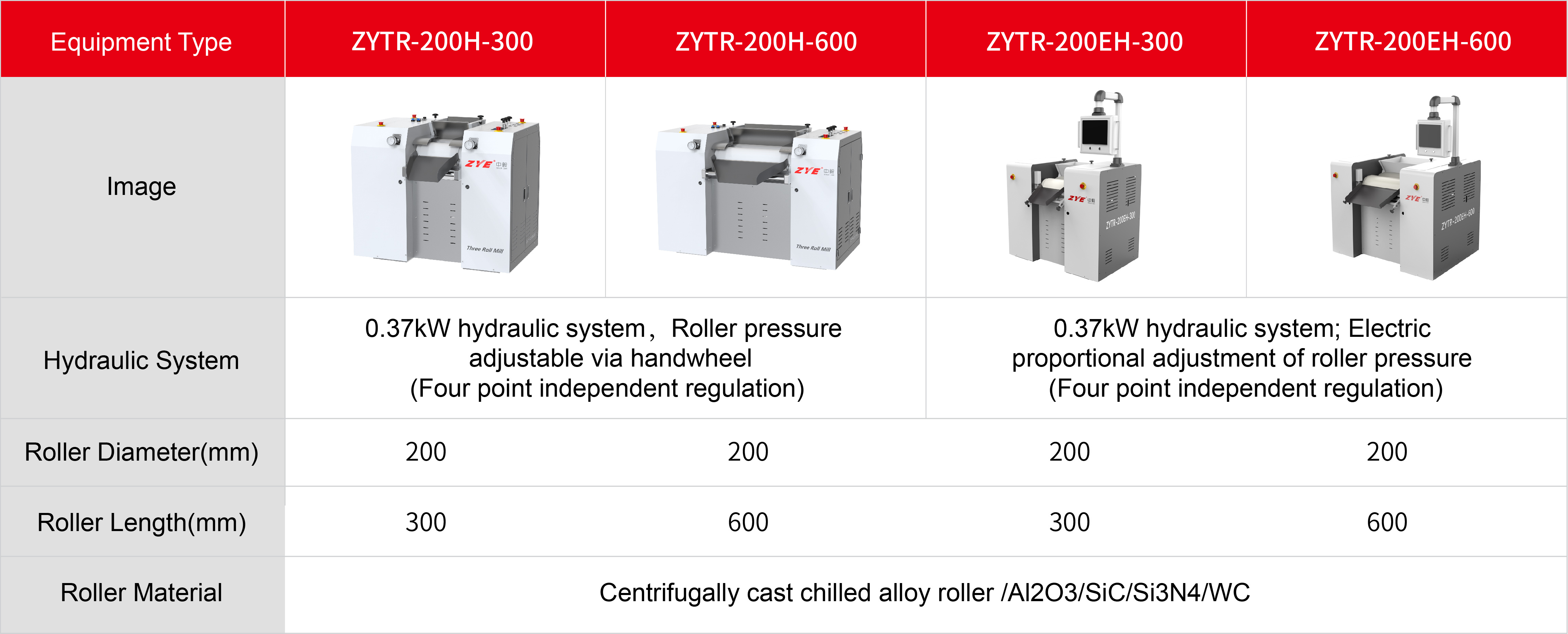

Recommended Model: