The Bubble Buster Of Glue Materials - Centrifugal Vacuum Mixer To Achieve Seamless Bonding Effect

Glue defoaming is an important process in the manufacturing process of basic industry. By using a centrifugal vacuum mixer, the tiny bubbles in the glue can be effectively removed and the performance and appearance of the product can be improved. This article will introduce how to efficiently use the centrifugal vacuum mixer for glue debubbling techniques.

First of all, choose the right centrifugal vacuum mixer. Different defoaming machines have different characteristics and functions. When choosing a centrifugal vacuum mixer, it is necessary to determine according to the nature of the glue and the degree of defrosting required. Different defoaming mixing processes and equipment directly affect the physical and chemical properties of materials, which determine the specific application of materials in industry.

Then choosing a defoaming machine that meets the needs of the application is particularly critical. The non-intervention-type centrifugal vacuum mixer developed and launched by ZYE has the functions of temperature control, mixing, defoaming and temperature measurement, which is suitable for the different viscosity of materials, do not damage the material, and improve the material performance and meet the application needs of higher standards.

Here is an example

Defoaming equipment: YZE centrifugal vacuum mixer ZYMC-180HV

Defoaming material: resin and filler

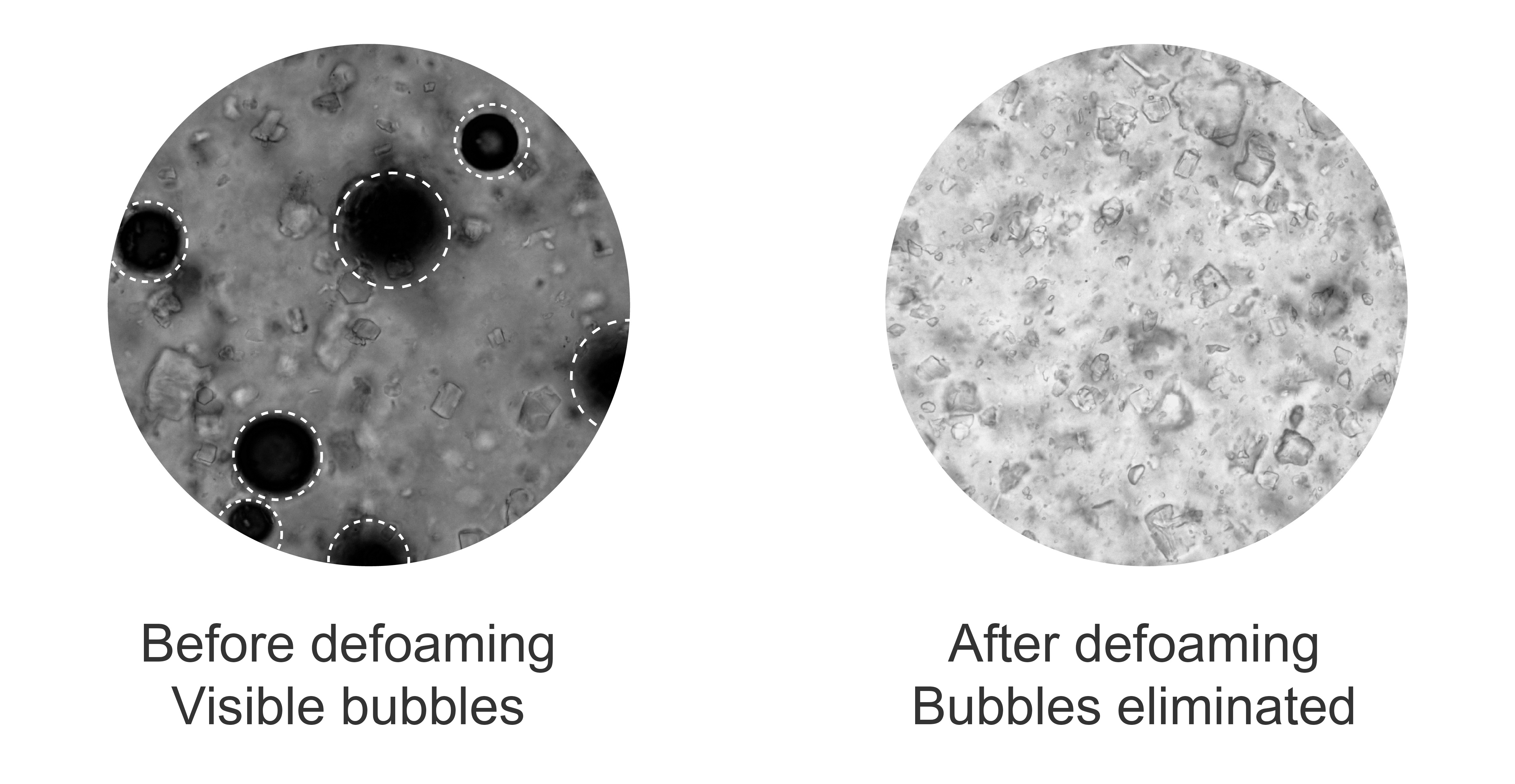

Comparison of the effect before and after defoaming

Comparison of the effect by microscope before and after defoaming

Procedure for defoaming

Preparation: Before starting the debubbling, ensure that the working environment of the centrifugal vacuum mixer is clean and tidy. Clean mixing cups and defoaming equipment to ensure that no impurities and dirt affect the defoaming effect.

Set parameters: According to the nature of the glue and the degree of defoaming, set the parameters of the centrifugal vacuum mixer, including mixing speed, vacuum degree and defoaming time and other parameters. Adjust the parameters according to the experience or experimental results to obtain the best defoaming effect.

Control operation time: The defoaming time should not be too long nor too short. Too long debubbling time may cause the quality of the glue to decline, and too short debubbling time can not completely remove the bubbles. Therefore, it is necessary to control the defoaming time according to the actual situation to ensure the best results.

Monitor the defoaming process: During the defoaming process, closely observe the state of the glue. Pay attention to observe whether the number and size of bubbles have a significant downward trend, and whether the uniformity of the glue is improved. If the defoaming effect is not satisfactory, the parameters can be adjusted or other measures can be taken to improve.

Follow-up procedure: After the debubbling is complete, perform other necessary processing on the debubbling glue in time, such as filtering and storage. Ensure the quality and reliability of the glue for the subsequent production process.

Through the above skills and methods, you can efficiently use the centrifugal vacuum mixer for glue defoaming. Proper selection of the debubbling machine, preparation, setting parameters, controlling operation time, monitoring the debubbling process, and subsequent treatment are all key steps. Through continuous practice and experience summary, the defoaming efficiency can be further improved and the performance and appearance of the product can be improved as well.