Industry Solution : The Ultimate Dispersion Solution For Nail Polish - Achieving Fine Dispersion From 100μm To 10μm

There are records of using beeswax, protein and gelatin to make cosmetics for nail beauty by Chinese women as early as 1000BC. Hand maintenance and nail decoration have long been a symbol of human social status, and nails are the most exciting part of the hand. In the 1930s, nail beauty began to appear in Europe and the United States in the modern sense, so a variety of fashion nail art came into being and sweep around the world with its simple and personalized characteristics.

In the 1980s, with the continuous maturity of UV curing technology, a new nail beauty technology called "phototherapy nail art" appeared in Europe and the United States. It has also developed rapidly in the 21st century, especially in the past decade. The market has become increasingly civilian. With the introduction of "phototherapy nail art" technology, the craze of nail glue is also gradually emerging in nail beauty venues in cities and towns across China.

Nail varnish, also known as nail polish glue, has been widely used in the nail industry in recent years. Compared with general nail polish, nail varnish has the characteristics of environmental protection, non-toxic, health and safety. In addition, it is compatible with the common advantages of glue and nail polish, with full and clear color, convenient application and longer lasting luster, so nail varnish has gradually replaced nail polish. UV nail varnish is mainly composed of light curing resin, active diluent, photoinitiator, and various additives (pigments, fillers). The photoinitiator is induced to produce free radicals by ultraviolet light, and then polymerization crosslinking of resin and active diluent is triggered.

At this stage, uv nail varnish has the following advantages:

① High efficiency: under ultraviolet lamp irradiation, it can be cured completely within two minutes;

② Environmentally friendly: oligomer and active diluent are involved in the curing film forming process, no solvent volatilization;

③ Performance: high transparency after curing film;

④ It becomes a coating with excellent weather resistance and no yellowing;

⑤ The coating film has high crosslinking density, strong corrosion resistance and long retention time;

⑥ According to the application, different performance requirements of UV nail varnish are developed.

As a composite component, the dispersion and uniformity of each material in nail varnish after mixing often have a great impact on its color and properties after curing. To solve the above problems, we use ZYTR-80E three roll mill machine developed by ZYE to evenly disperse UV nail polish glue. ZYTR-80E achieves the effect of grinding dispersion through the horizontal three roller surface extrusion, different steering and speed difference generated by the shear force. ZYTR-80E does not damage the surface topography of the material while achieve the purpose of depolymerization through precision spacing control.

Customer name: KNS

Experimental equipment: ZYTR-80E (zirconia roller), cermet scarping knife, Nikon optical microscope

Experimental material: UV curing nail varnish

Experimental objective: To make the material dispersion more uniform by ZYTR-80E

Experimental Procedure:

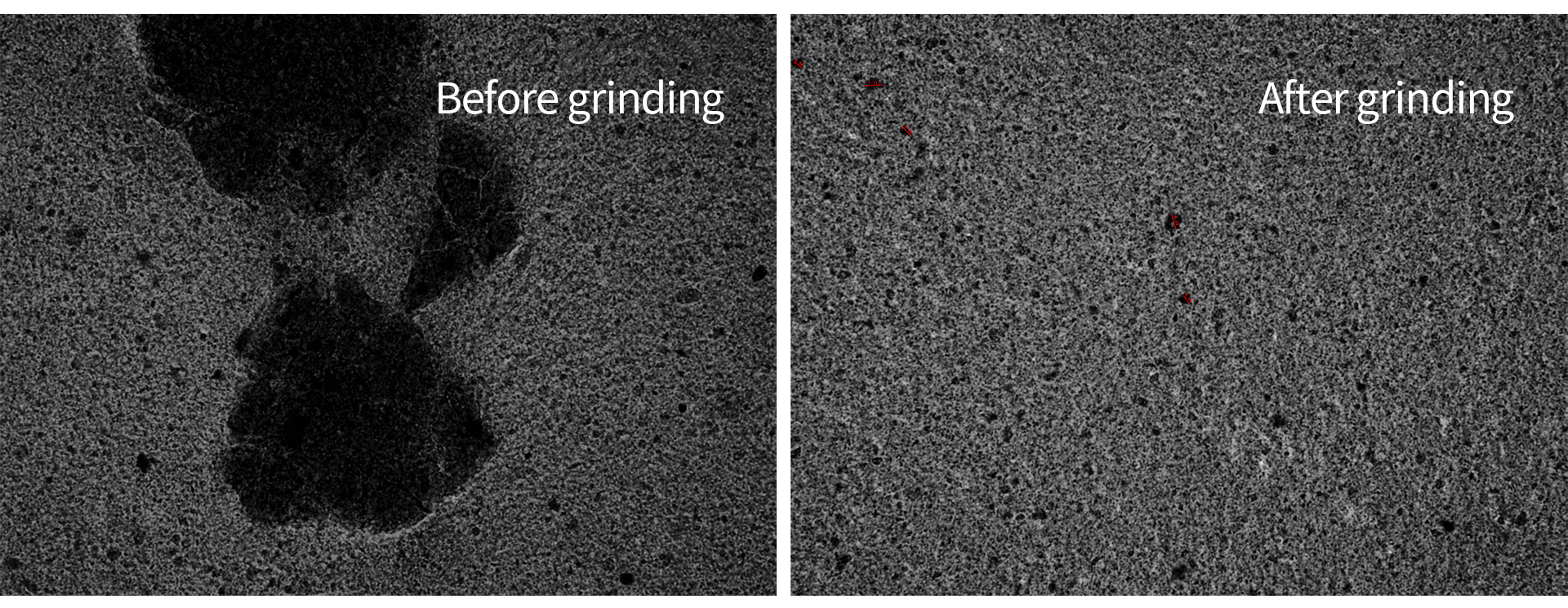

1. A small amount of premixed material was used to detect the initial particle size of the material using Nikon optical microscope. The initial agglomeration of the material was larger than 100 microns.

2. ZYTR-80E was used to grind and got the slurry (grinding twice, minimum discharge gap of 20 microns). The overall slurry is more delicate and shiny. The discharge is uniform without leakage during the operation.

3. A small amount of ground material was detected by Nikon optical microscope to check the particle size. After grinding, no particles larger than 10 microns were observed by microscope.

Experimental Data:

The state under the microscope

Experimental Photos:

Experimental Result Analysis:

Microscopic observations of the premixed material show that there are agglomerations larger than 100 microns. After dispersion by three roll mill ZYTR-80E, it was found that the particles in the agglomerations have been less than 10 microns by the observation of microscope. The results show that the depolymerization effect of the three roll mill is obvious, and the dispersion and uniformity of the material after grinding are greatly improved.

About ZYE:

Founded in 2007, ZYE is a high-end precision equipment manufacturer in China's ultra-segmented field. Focusing on the research and development, manufacturing and sales of mixing, dispersing, defoaming, filling, coating and testing technology, we are committed to providing customers with full chain solutions. ZYE's equipment are widely used in adhesives, ink coating, electronic industry, electronic paste, new energy, nano new materials, medicine, cosmetics and other fields. At present, we have more than 2,000 domestic and international customers, accumulated more than 10,000 experimental reports and records. Our equipment are spread across more than 30 countries in the world, such as: Germany, Britain, France, Switzerland, the United States, Canada, Japan, South Korea, Israel, Singapore, Malaysia and so on.

After nearly 17 years of grinding and precipitation, ZYE has accumulated more than 100 patents, soft materials, trademarks and certifications, has got the "ISO9001 quality management system" certification, and won the "National high-tech enterprise", "specialized and special new small and medium-sized enterprises", "Gusu Innovation and entrepreneurship leading talent enterprise" and "Wujiang District science and Technology leading talent Enterprise" and other honors. ZYE adheres to the line of customer application as the center and endeavor as the foundation, builds the high-end brand of the industry, takes the road of "brand, quality", and contributes to the achievement of China's equipment.

Material properties are an important process in the manufacturing process of basic industries, and the mixing and dispersion of high-end fine materials is the core link in the preparation process, and the effect of mixing and dispersion directly affects the performance and practical application of materials. Different mixing processes and equipment affect the physical and chemical properties of materials, such as strength, thermal conductivity, electrical properties, mechanical properties, and so on. These properties determine the specific application of the material in industry.

ZYE's mixing and dispersing equipment can improve material performance, not only with temperature control, mixing, defoaming, temperature measurement functions, but also can be applied to materials with different viscosity. It can not only damage the material, but also better improve the material performance to meet the application needs of higher standards.

ZYE equipment:

Planetary Centrifugal Mixer

Planetary centrifugal mixer is a pre-dispersion of base materials and auxiliary materials and a material mixing defoaming device developed by ZYE based on the principle of revolution and rotation. It realizes the segmsegmical unequal speed oscillation operation of the rotating carrier by means of planetary gear structure, motion control card and unequal speed control software system (hardware + software), and then drives the materials in the rotating carrier to mix evenly. It can realize the functions of temperature control, mixing, defoaming and temperature measurement at the same time, and greatly improve the efficiency and quality of the developed materials.

Precision three roll mill

Precision three roll mill, independently researched and developed by ZTE, is a grinding and dispersion equipment for agglomeration. It uses the shear force generated by the horizontal three rollers of different steering and different speed to grind, disperse, homogenize a certain viscous material, so as to improve the dispersion of the material particle size concentration. It not only solves the stability of the micron level control gap structure of the machine, realizes the automatic calibration of the roll gap, ensures the stability of the gap in each operation, but also effectively controls the temperature and quality of the material, and improves and enhances the product performance. At the same time, it has many advantages such as real-time monitoring of dispersed pressure conditions, real-time data transmission, traceable query history, real-time monitoring and convenient timely adjustment.