The Xiaomi SU7 Boom: Meet The Unsung Hero Powering The Battery Industry

2025-07-21 09:00

Recently, the spotlight in the automotive industry has undoubtedly been on the Xiaomi SU7. Since its launch, the SU7 has quickly become a market sensation, thanks to its outstanding performance, sleek design, and cutting-edge smart features. In February 2025 alone, it delivered over 20,000 units, and has maintained a monthly delivery volume exceeding 20,000 for five consecutive months — with total deliveries surpassing 183,800 units to date. This achievement is nothing short of impressive.

While discussions around Xiaomi SU7 often focus on its driving experience and intelligent cockpit, one critical component is often overlooked — the battery manufacturing process. And this is precisely where our technology steps into the spotlight.

The "Core" Behind Xiaomi SU7’s Power

The Xiaomi SU7’s exceptional performance owes much to its high-performance battery systems. Different versions of the SU7 are equipped with distinct battery configurations to meet varying user needs:

Standard Version: Comes with a 73.6 kWh lithium iron phosphate (LFP) battery supplied by BYD FinDreams Power or CATL (from June 2024, dual suppliers are randomly matched to vehicles).

Pro Version: Features a 94.3 kWh LFP battery exclusively utilizing CATL’s Shenxing Battery Technology, enabling a CLTC range of up to 830 km. Although it charges slightly slower than the Max version, it offers a solid balance of range and stability.

Max / Ultra Versions: Equipped with a 101 kWh NCM ternary lithium battery (CATL’s Qilin Battery). These versions support 800V ultra-fast charging, adding 200 km of range in just 5 minutes and reaching 510 km in 15 minutes. The battery adopts a cell-reversal architecture that can rapidly discharge heat downward during thermal runaway events, enhancing passenger safety.

These advanced battery systems provide the Xiaomi SU7 with powerful acceleration and long-lasting endurance, forming one of its core competitive advantages.

A Key Force in the New Energy Battery Industry

Behind the rapid evolution and upgrades of new energy vehicle batteries lies not only the tireless efforts of researchers, but also the silent contribution of a "behind-the-scenes hero"—the defoaming mixer.

As a specialized manufacturer of defoaming mixers, ZYE Technology (ZVE) deeply understands the critical role of mixing and defoaming in battery production. In the preparation of battery materials, the defoaming mixer has become a core piece of equipment, ensuring the uniform dispersion of materials while effectively removing microbubbles that could compromise battery performance and safety.

Whether it's slurry mixing for electrodes or high-viscosity paste preparation for solid-state batteries, ZYE’s defoaming solutions are helping leading battery manufacturers achieve higher consistency, stability, and energy density in their products.

Pushing the Limits of Next-Generation Battery Materials

In the development of new-generation battery materials—whether it's solid electrolytes for solid-state batteries, or emerging chemistries such as potassium-ion and zinc-based batteries—vacuum defoaming mixers play an irreplaceable role.

As battery technologies advance toward higher energy density, longer cycle life, and enhanced safety, the quality standards for battery materials are becoming increasingly stringent. ZYE’s vacuum defoaming mixers offer outstanding capabilities in uniform mixing and efficient air removal, enabling manufacturers to meet the demands of cutting-edge battery research and production.

By ensuring consistency at the microstructural level, ZYE’s equipment helps battery innovators overcome technical bottlenecks and accelerate breakthroughs in performance and reliability.

Take lithium-ion battery electrode slurry preparation as an example:

The slurry—typically composed of active materials, conductive agents, binders, and solvents—is prone to air entrapment during mixing, leading to bubble formation. Additionally, agglomeration of active particles may result in poor dispersion uniformity.

These issues directly impact the coating quality of electrode sheets and compromise the overall performance stability of the battery.

ZYE’s vacuum defoaming mixers are engineered to solve these challenges by simultaneously delivering high-shear mixing and vacuum degassing, ensuring slurry homogeneity while eliminating microbubbles.

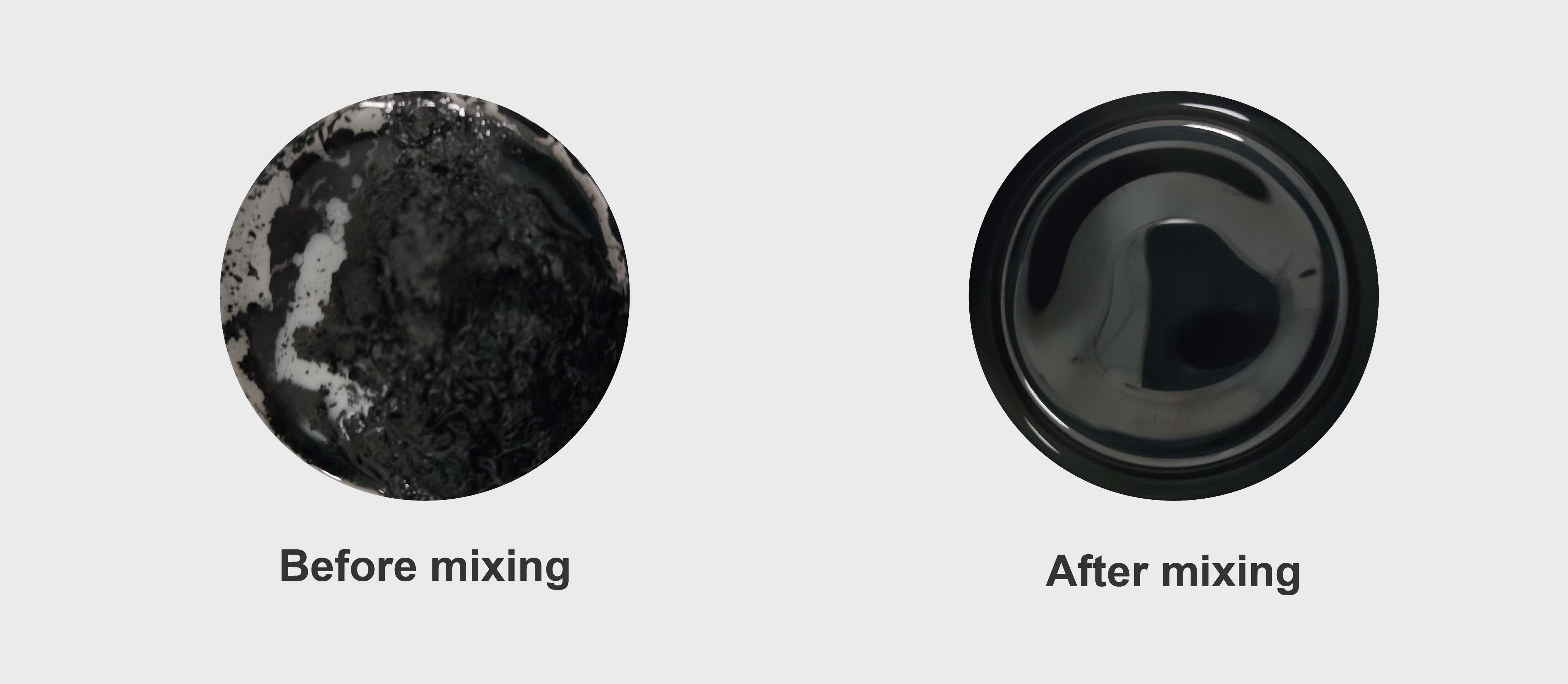

Before & After: Mixing Effect of Lithium Battery Anode Materials

ZVE Vacuum Planetary Mixer, developed by ZYE Technology, offers an efficient and reliable solution for the critical challenges in battery slurry preparation—such as air entrapment and poor dispersion.

High-Efficiency Vacuum System: Effectively removes micron-sized bubbles within the slurry, enhancing density and preventing coating defects like pinholes and missing spots, which can impact electrical performance.

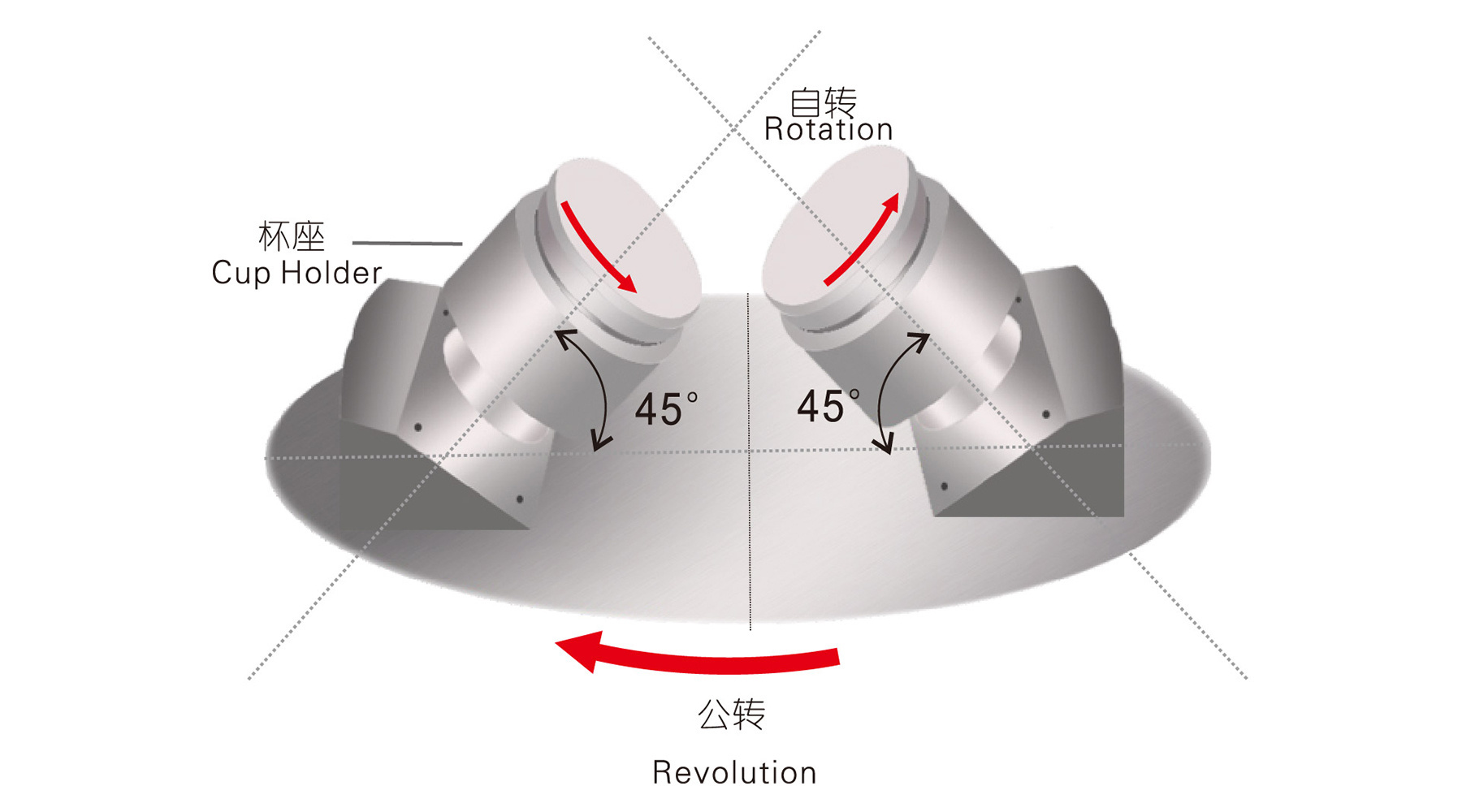

Planetary Mixing Mechanism: Utilizes tunable revolution and rotation speeds to generate strong centrifugal force, ensuring uniform mixing of high-viscosity materials like electrode slurries while preserving material integrity.

Advanced Touchscreen Control: Supports multi-stage programmable settings including vacuum level, mixing speed, duration, and modes, enabling precise process replication and minimizing human error—ensuring batch-to-batch consistency.

The ZVE series is suitable for various production scales, from lab-scale R&D to pilot lines and mass production, helping battery manufacturers achieve breakthroughs in both technology and productivity.

Collaborating to Drive the New Energy Industry Forward

For 18 years, ZYE’s ZVE vacuum defoaming mixers have consistently delivered stable and reliable performance with excellent mixing and defoaming effects, making a significant impact in the new energy battery sector.

Backed by strong technical expertise and robust product quality, ZYE has successfully served more than 20 leading new energy battery manufacturers, including CATL and Honeycomb Energy.

Throughout the entire battery production process of these industry leaders, ZYE’s vacuum defoaming mixers have provided steadfast support through stable operation and precise process control, ensuring the high-quality preparation of battery materials.

ZYE continues to play a vital role in the ongoing advancement and growth of the new energy vehicle industry.

Key Partners in the New Energy Battery Industry

The phenomenal success of the Xiaomi SU7 reflects the immense potential of the new energy vehicle (NEV) market and the strong demand among consumers for high-quality electric vehicles. The rapid growth of this market would not be possible without the collaborative efforts of the entire industry chain.

As a manufacturer specializing in precision mixing and dispersion equipment, ZVE by ZYE Technology remains committed to continuous technological innovation and product optimization. We are dedicated to providing more advanced, efficient, and reliable equipment for battery manufacturers, working hand in hand with industry leaders to drive the development of the new energy battery sector and inject lasting momentum into the NEV industry.

Looking ahead, as NEV technologies continue to evolve, we believe that vacuum defoaming mixers will play an even more critical role in battery production. We look forward to partnering with more enterprises across the new energy sector, and together, writing a new chapter of excellence in this promising blue ocean of opportunities.