3D Printing + Biomedical Materials: Unlocking a New Era of Personalized Precision Medicine

2025-10-20 18:00

Globally, population aging is an irreversible trend. This has led to explosive growth in the demand for medical products such as orthopedic implants, cardiovascular stents, dental restorations, and personalized surgical guides. Traditional standardized medical devices struggle to meet each patient's unique physiological structure and the demand for a high-quality, healthy life. Against this backdrop, the integration of 3D printing technology and biomedical materials is initiating a revolution in "personalized precision medicine."

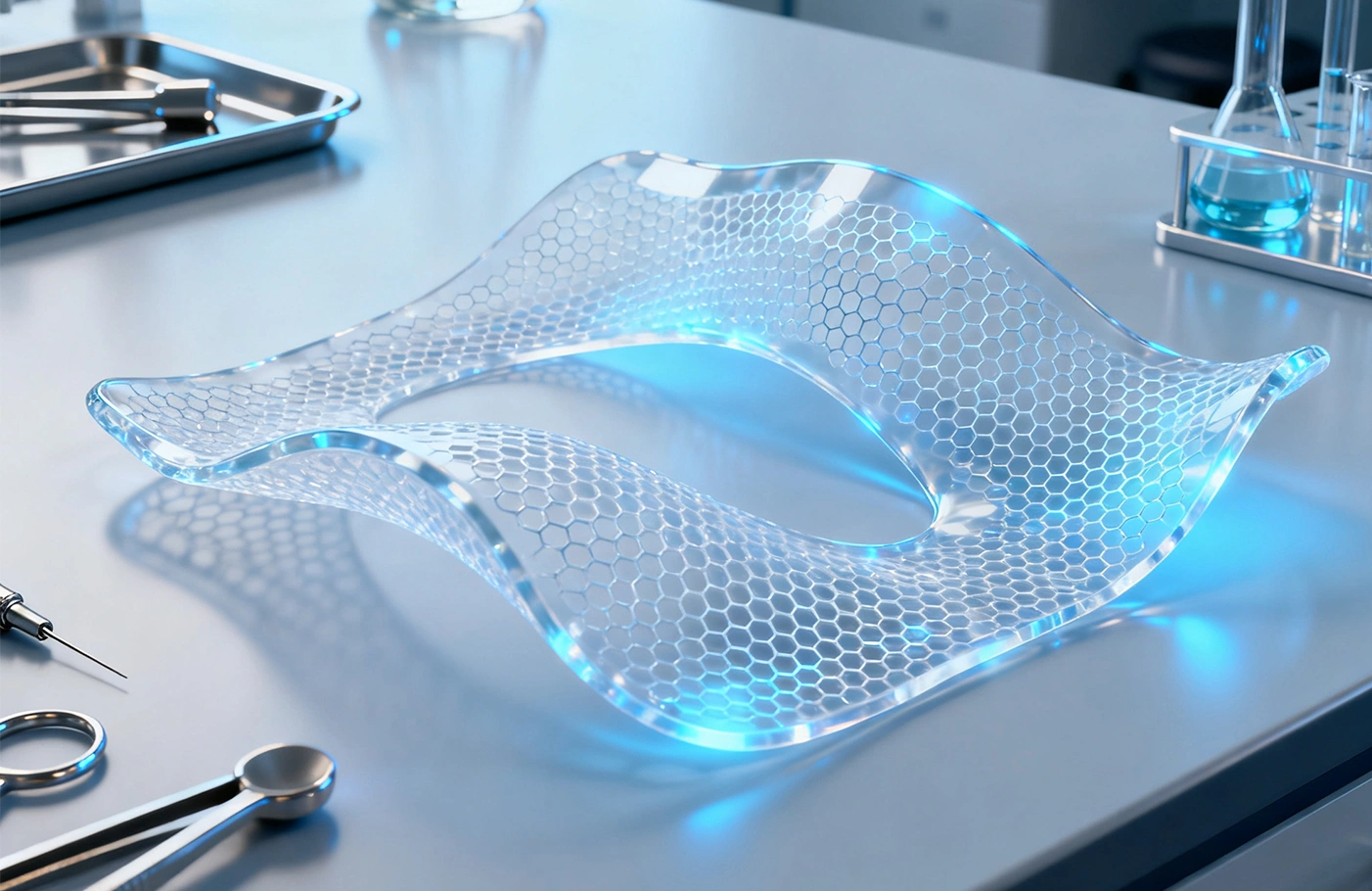

3D printing, also known as additive manufacturing, distinguishes itself from traditional manufacturing through its core appeal: the ability to rapidly and accurately manufacture complex medical products that perfectly match a patient's anatomical structure, based on medical imaging data (such as CT, MRI). Whether it's an irregularly shaped craniomaxillofacial bone plate or a tissue engineering scaffold filled with intricate micro-channels, 3D printing can achieve them all. The crucial support behind this seemingly "magical" manufacturing process is precisely those high-performance 3D printing biomedical materials – they are the "soul ink" of 3D printed medical products, directly determining the safety, effectiveness, and applicability of the final product.

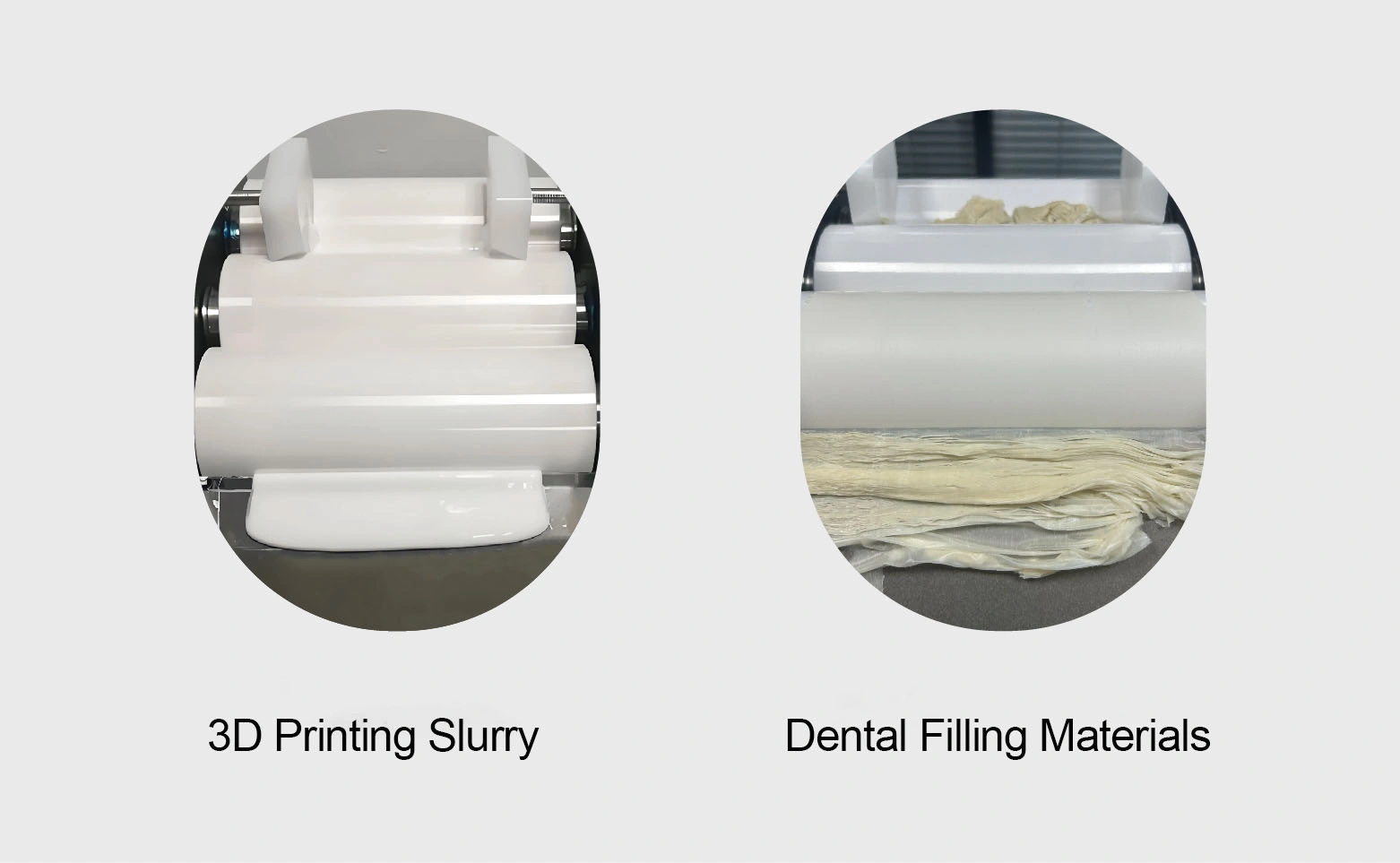

Before these high-performance 3D printing biomaterials can become qualified "ink," their preparation process demands extreme uniformity and purity. This is precisely where ZYE's core value lies. The Three Roll Mill and Vacuum Planetary Mixer developed and produced by ZYE, leveraging their industry-leading technical advantages, have become key supporting equipment in the material preparation stage. As a National High-Tech Enterprise deeply involved in the precision manufacturing field, ZYE always positions itself as the "Material Uniformity Expert," providing professional solutions for high-end sectors like biomedical materials.

Industry Application of the Three Roll Mill

In the preparation of biomedical materials, to enhance the mechanical properties or impart special functions, it is often necessary to introduce nano-scale reinforcing phases into the matrix material. For example, to allow hydrogels to mimic the mechanical strength of natural bone or cartilage, nano-hydroxyapatite, bioactive glass, carbon nanotubes, cellulose nanocrystals, etc., are added. However, due to their large surface area and high surface energy, these nanoparticles are extremely prone to attract each other and form micron-sized agglomerates – these agglomerates can be called the "invisible killers" of material performance; on one hand, they can become stress concentration points within the material, leading to a significant decrease in the mechanical properties of the scaffold under force, and even potentially causing premature fracture during use, triggering medical risks; on the other hand, during the 3D printing process, agglomerates can also clog the fine printing nozzles, causing print interruptions or product defects.

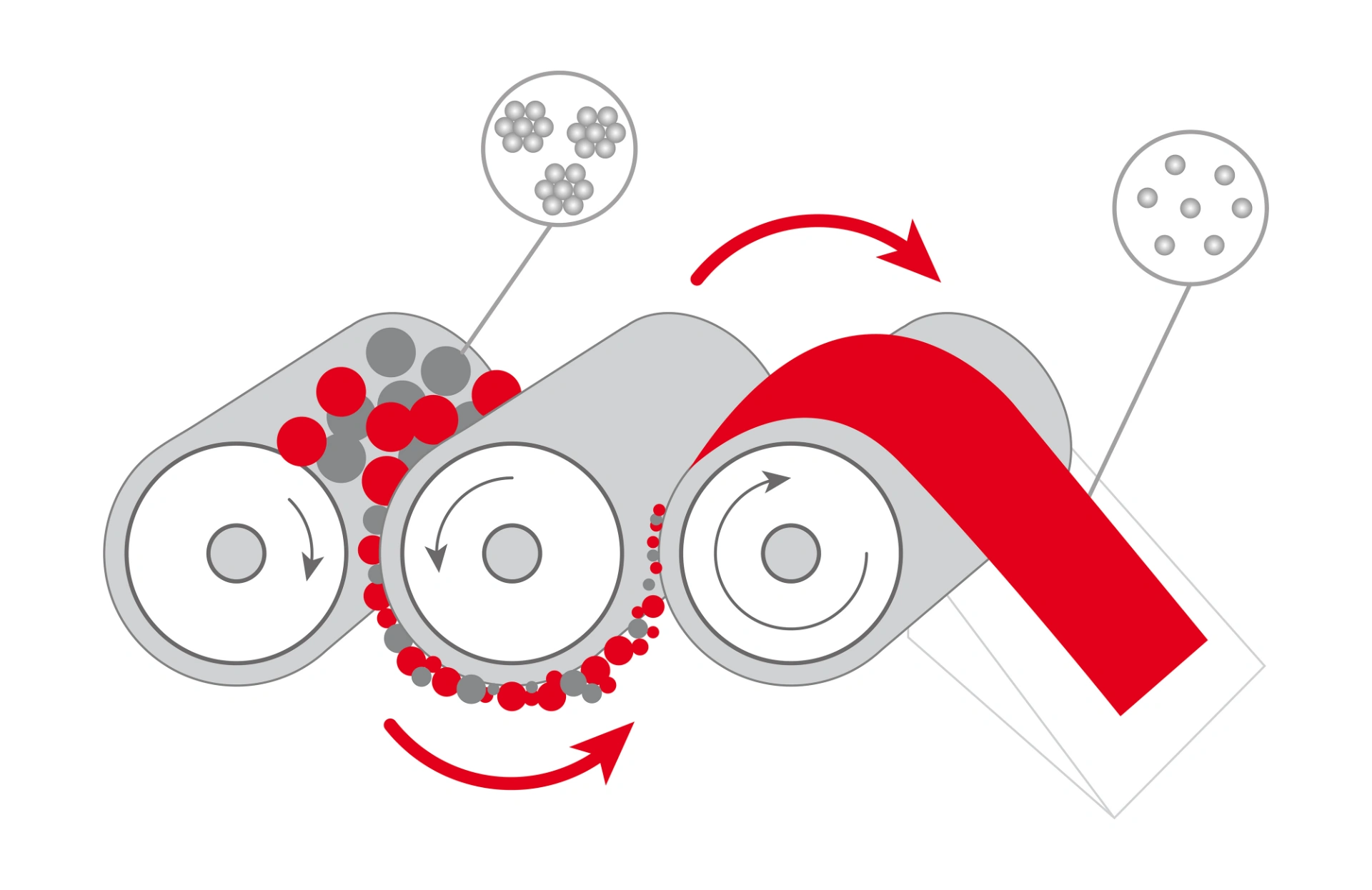

ZYE's precision ceramic Three Roll Mill demonstrates outstanding solution value. Through the enormous shear force and compressive force generated between the three ceramic rollers rotating at different speeds and closely fitted, it can, like a "precision scalpel," completely "tear apart" the nanoparticle agglomerates, achieving a dispersion precision reaching the sub-micron or nano level. Compared to traditional metal rollers, the ceramic rollers adopted by ZYE have the advantages of high corrosion resistance, high wear resistance, and high strength, ensuring purity and precision when handling biomedical materials.

Material grinding performance with a three roll mill

Furthermore, to ensure the precision and structural strength of 3D printed products, bioinks usually need to contain high concentrations of polymers and fillers, which inevitably leads to extremely high paste viscosity, poor fluidity, and a greater tendency for filler agglomeration. ZYE's Three Roll Mill shows strong advantages when processing high-viscosity pastes: as the most effective grinding and dispersing equipment for high-viscosity materials, under high-speed shear action, it can not only achieve uniform dispersion of fillers but also, by breaking some intermolecular forces, reduce the apparent viscosity of the paste to a certain extent, improving its rheology. This makes the high-viscosity paste more easily pass through the nozzles of extrusion-based 3D printers, ensuring the continuity and smoothness of the printing process, and avoiding problems such as poor interlayer bonding or structural deformation caused by poor paste fluidity.

Industry Application of the Vacuum Planetary Mixer

During the mixing of hydrogel prepolymers, crosslinking agents, and fillers, air is inevitably entrapped inside the paste, forming microbubbles or even visible bubbles. If these bubbles are not removed, they will be "fixed" inside the scaffold during the subsequent crosslinking and curing process, forming randomly distributed defect pores – they not only destroy the structural integrity of the scaffold, reducing mechanical performance, but also block the connectivity of internal channels within the scaffold, affecting cell migration, nutrient transport, and metabolic waste removal, severely restricting the functional realization of the tissue engineering scaffold.

ZYE's Vacuum Planetary Mixer is precisely the professional "solution" to this problem. It uses a centrifugal design of revolution + rotation, combined with a built-in vacuum defoaming device, which can achieve simultaneous mixing and defoaming. The entire process takes only 1-3 minutes and can effectively remove sub-micron bubbles, achieving industry-leading defoaming results. This non-intrusive processing method avoids the damage to materials caused by traditional paddle stirring, and has no stirring dead angles, ensuring that all parts of the paste achieve ideal defoaming results.

Mixing and defoaming performance of planetary mixer

After the paste treated by ZYE's Vacuum Planetary Mixer undergoes crosslinking and curing to form a porous scaffold, its pore structure consists entirely of actively designed, interconnected ideal channels – the size, distribution, and connectivity of these channels can precisely match the needs of tissue regeneration, providing the optimal microenvironment for cell growth and proliferation, nutrient exchange, and metabolic waste discharge, ensuring that the tissue engineering scaffold can truly play its core role in guiding tissue regeneration.

From the medical demand changes driven by global aging, to the breakthroughs in personalized medicine brought by the integration of 3D printing and biomedical materials, and further to the extreme guarantee of material quality provided by ZYE's Three Roll Mill and Vacuum Planetary Mixer, each link is interconnected, collectively promoting the transition of "personalized precision medicine" from concept to reality. In the future, with the continuous innovation in material science, 3D printing technology, and precision manufacturing equipment, ZYE will continue to adhere to the philosophy of "Being Pragmatic and Pursuing Excellence," providing more advanced technical support for the preparation of high-end medical materials, assisting the emergence of more medical products that fit human body requirements and combine safety and effectiveness, and opening a broader future for the cause of human health.