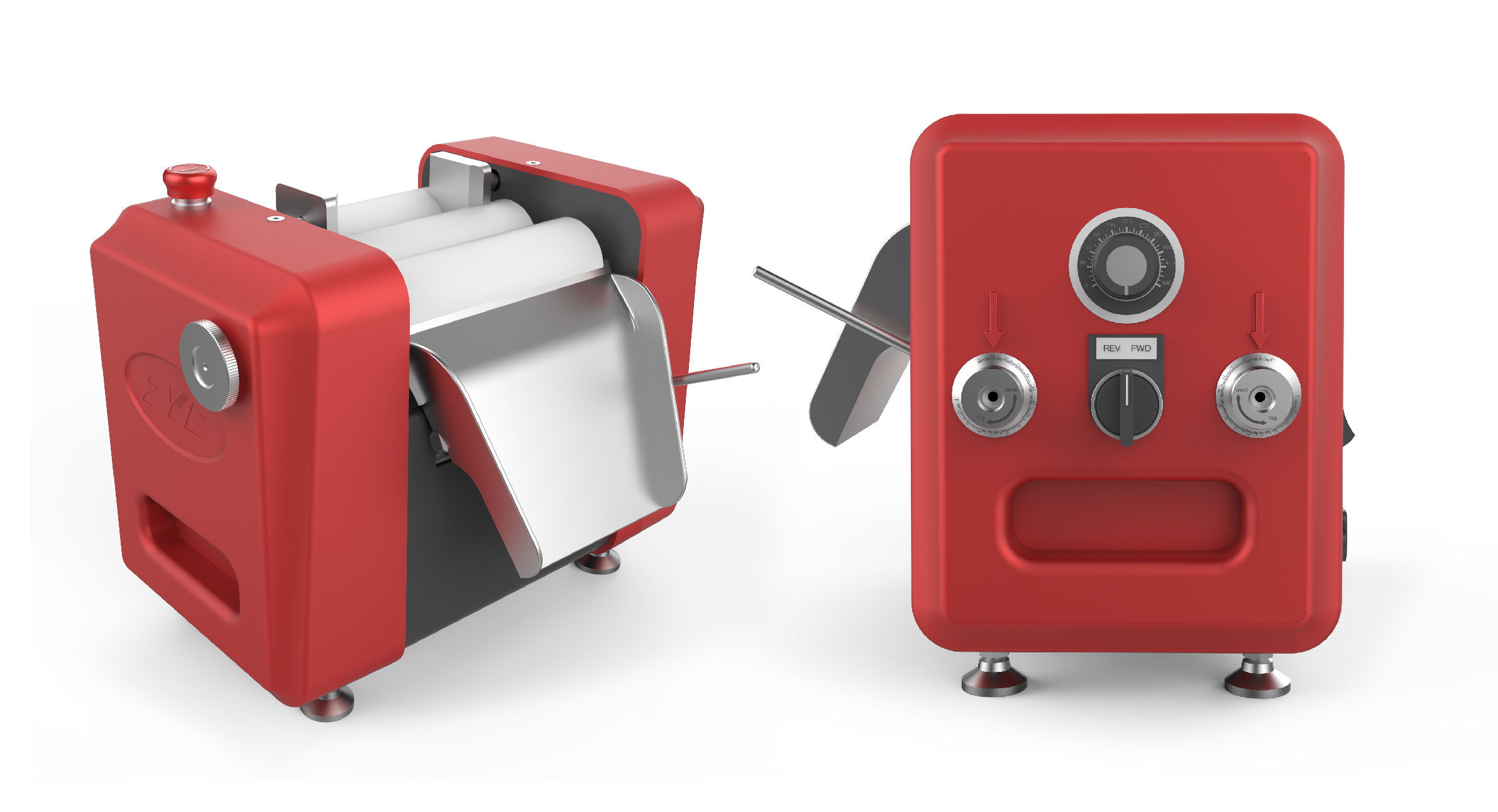

The Secret Weapon On The Lipstick Production: A Detailed Description Of The Operation Of The Three Roll Mill Machine

2024-12-20 14:04

On a summer's day, will a flowing dress and matching lipstick lift your mood? So where do these colorful lipsticks come from? The lipstick production machine, that you don't know,three roll mill machine. ZYE technology will share with you the production process of lipstick in this article.

The basic ingredients of lipstick production include: wax, grease, color and pigment. Typical ingredients are 20 to 30 percent wax, 50 to 70 percent grease, and 5 to 15 percent pigment.

First, it is necessary to mix the pigment with the right amount of grease (the ideal ratio of pigment and grease is two parts of grease to one part of pigment), and then grind the mixture through a three roll mill machine to make the pigment polymer evenly dispersed.

Second, the evenly dispersed pigment and grease mixture is added to the dissolved wax and remaining grease (a small amount of fragrance can also be added) for mixing and re-processing through a three roll mill machine to achieve the ideal particle size (usually 20 microns). The three roll mill machine is a very effective device for evenly dispersing lipstick pigments;

Third, the lipstick needs to be formed and cooled in the mold;

Four, increase the surface luster through the burning in the combustion cabinet. Add a series of beautiful external packaging, which is what you see the lipstick looks like.

The three roll mill machine here is mainly suitable for pastes or high-viscosity materials that need to be dispersed and require high fineness. The roller center can pass cooling water during the operation of the equipment, which plays a good cooling effect. The conventional temperature rise is less than 10 degrees Celsius, and the product quality is guaranteed. Through the surface of the three horizontal rollers, the material enters between the back roller and the middle roller, and is squeezed by the rollers, then the product particles become finer. And then taken out by the fast roller, and the end of the fast roller is equipped with a scraping knife to separate the material from the roller and then fallen into the collection bucket. The distance between rollers can be manually adjusted to achieve grinding effect with friction at different speeds.