Marketing Event | ZYE Technology Shines At 2025 Guangzhou International Ink Industry Exhibition: Pioneering Industry Innovation With Cutting-Edge Equipment

2025-06-09 15:01

From June 5th to 7th, the 2025 Guangzhou International Ink Industry Exhibition successfully concluded at the Poly World Trade Expo Center in Pazhou, Guangzhou. Centered around the theme "Green Innovation, Inky World," the event brought together global industry elites and cutting-edge advancements, serving as a premier platform for exchange and collaboration. As a leading Chinese manufacturer of high-end precision equipment in ultra-niche sectors, ZYE Technology made a remarkable appearance by showcasing its independently developed precision triple roller mill and planetary centrifugal mixer, achieving significant success.

This year's exhibition was grand in scale, comprehensively covering terminal applications across industries such as printing, packaging, labeling, dyeing, electronics, household chemicals, advertising, and food & beverage. It spotlighted products like inks, water-based inks, raw materials, ink equipment, water-based printing machinery, technologies & services, live full-color ink demonstrations, and printing consumables, driving the ink industry's green transformation and high-quality development. The event attracted ink enterprises, experts, and professionals from around the world.

ZYE Technology's booth stood out with a sleek and professional design, highlighting its products through live demonstrations and physical displays. The team provided in-depth technical explanations, allowing visitors to explore the principles, applications, and performance of the equipment. The booth drew crowds of industry clients, potential partners, and professionals, significantly boosting ZYE's brand visibility and product influence.

Highlights

At the exhibition, ZYE's precision triple roller mill garnered widespread attention. Designed for grinding, dispersing, and homogenizing high-viscosity materials, it leverages shear forces generated by the differential rotation speeds of three horizontally aligned rollers, effectively addressing challenges in micron-level gap stability control.

Meanwhile, ZYE's planetary centrifugal mixer (vacuum mixer) earned high acclaim for its efficiency and versatility. Capable of temperature control, mixing, defoaming, and temperature monitoring, it dramatically enhances material processing efficiency and quality, offering a breakthrough solution for ink production.

Through its dynamic participation, ZYE Technology further elevated its brand image and industry leadership, showcasing China's prowess in high-end precision equipment innovation to global audiences.

Technical Advantages

Material performance is a critical factor in industrial manufacturing, where mixing and dispersion are pivotal in high-end material preparation. The effectiveness of these processes directly impacts material properties and applications, including strength, thermal/electrical conductivity, and mechanical performance. ZYE Technology addresses these needs with its two flagship solutions: the triple roller mill and the planetary centrifugal mixer.

01

Planetary Centrifugal Mixer for Multi-Viscosity Materials

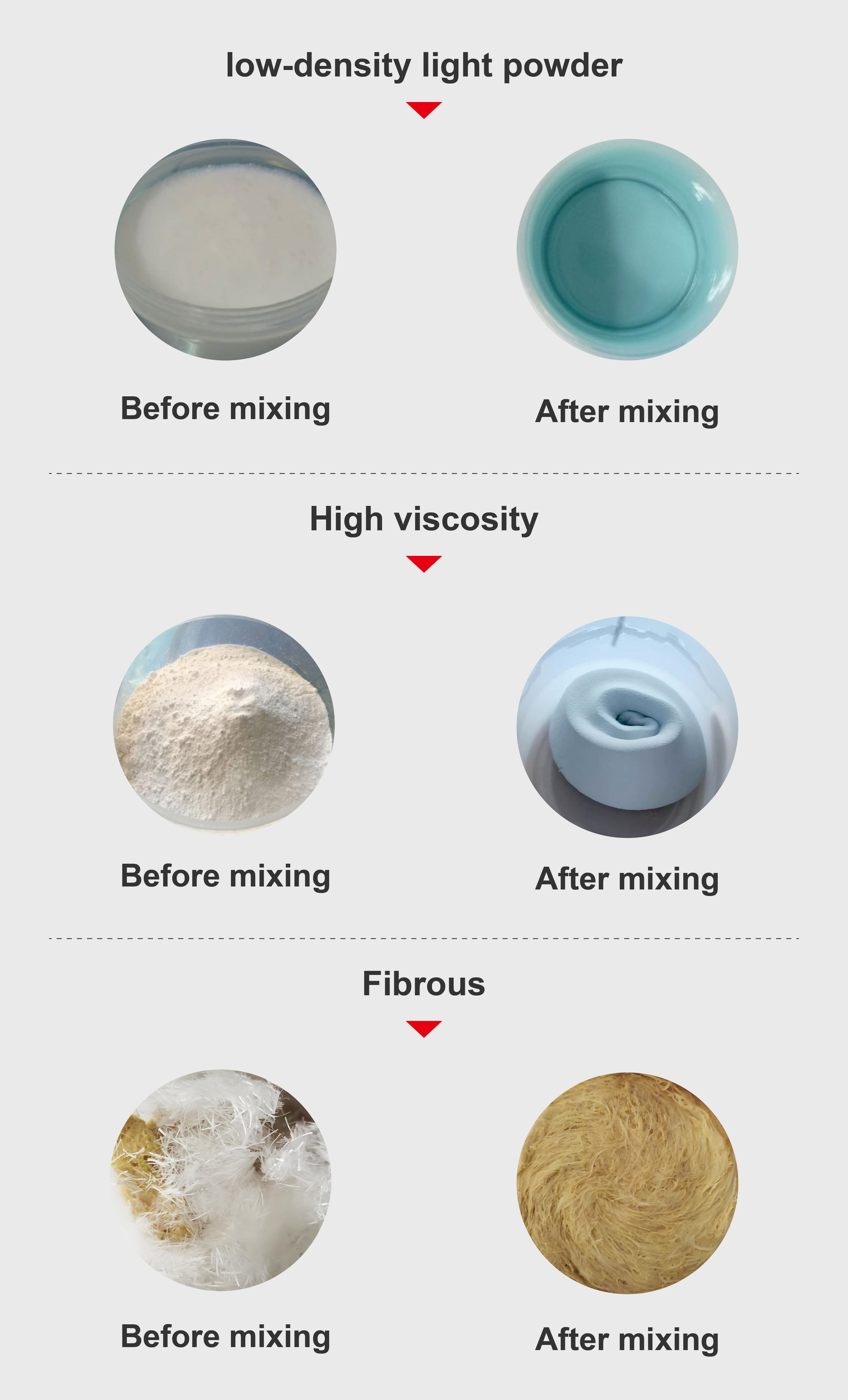

As the core medium of printing, ink quality dictates final print results. Residual bubbles cause pinholes and spots, while uneven mixing affects color strength and stability.

The ZYE vacuum defoaming mixer can handle up to 100 kg per batch, perfectly meeting large-scale production demands. It supports explosion-proof and refrigeration technology customization, providing robust safety assurance for the production of solvent-based inks, UV inks, and other materials containing volatile solvents. Additionally, its powerful multi-functional integration enables temperature control, mixing, defoaming, and temperature measurement, significantly improving the efficiency and quality of ink formulation while ensuring batch-to-batch consistency. Tailored to high-end industry needs, it delivers a full-chain solution with "large capacity + multi-functionality + smart technology", empowering enterprises to produce high-quality, high-performance ink products with enhanced efficiency.

Various materials are mixed by homogenizer

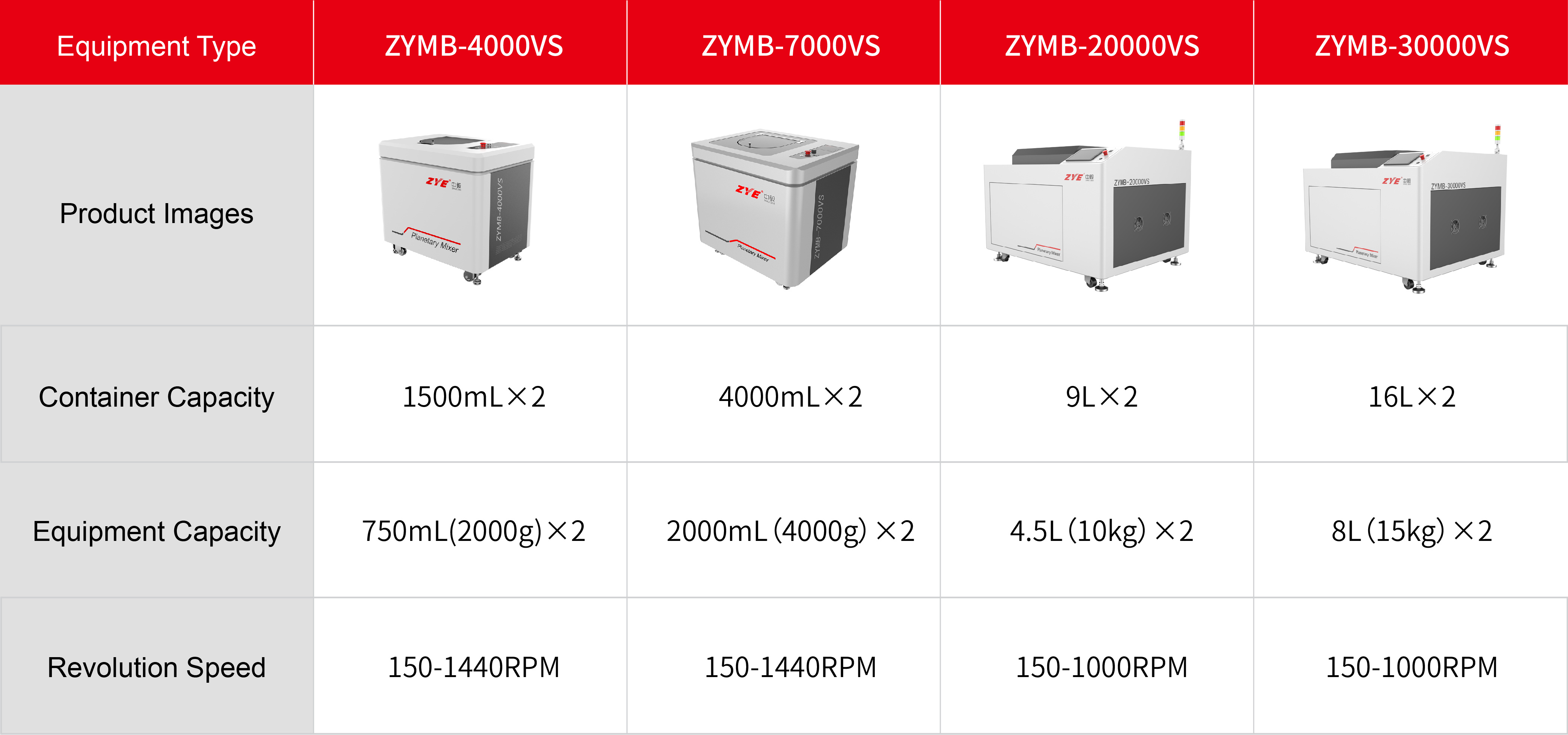

Various models available

02

Triple roller mill in Ink Applications

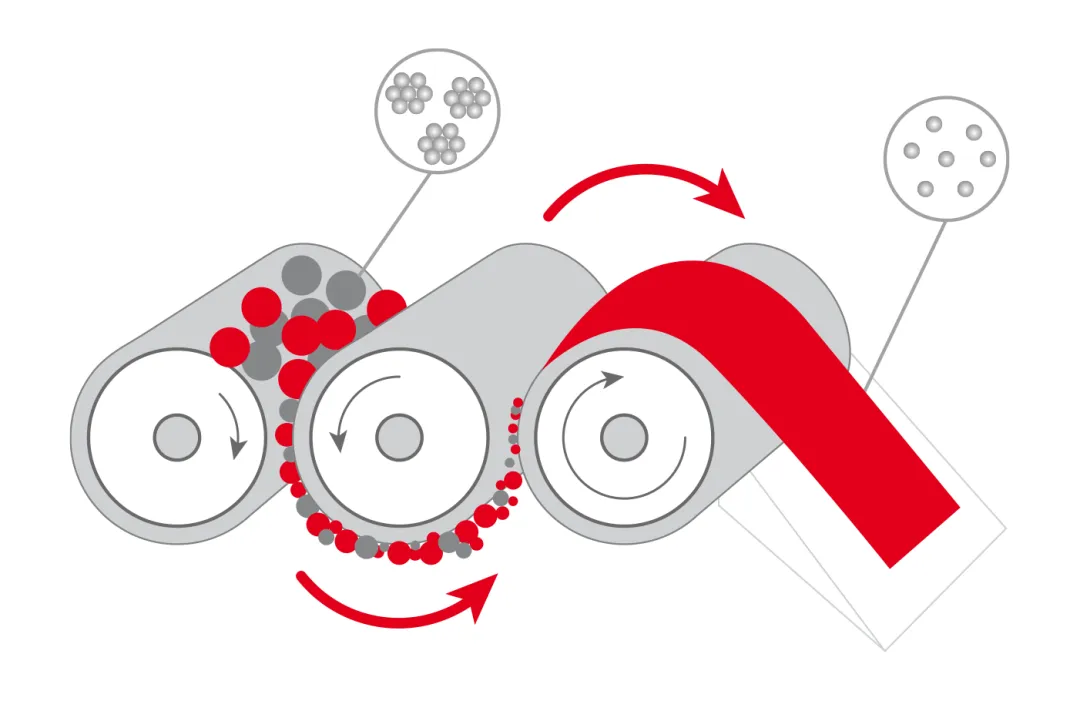

The triple roller mill is a core dispersion and grinding equipment in the ink industry, primarily used to uniformly disperse and refine pigments, resins, and other raw materials into micron-level particles. It plays a critical role in ensuring the fluidity and color stability of inks.

ZYE's triple roller mill is a precision-grade machine, serving as the most efficient dispersion equipment for medium-to-high-viscosity materials. It achieves sub-micron-level dispersion while delivering optimal particle size concentration. Widely used in the production of paints, inks, pigments, and plastic pastes, its core principle relies on the shear force generated by the opposing rotation and speed differential of three horizontally aligned rollers. Under ZYE's precise gap control, it effectively disperses and deagglomerates materials without damaging their surface morphology.

In the ink industry, high-viscosity inks (e.g., UV inks, offset glossy quick-drying inks) demand exceptional dispersion performance due to their strong cohesion and poor fluidity-an area where triple roller mills demonstrate outstanding advantages.

ZYE's precision triple roller mill leverages its unique shear, compression, and grinding mechanisms to refine pigment particles to micron-scale and uniformly disperse them within the system. It is ideal for high-end ink production (e.g., offset, gravure printing) and excels in high-viscosity ink processing and small-batch R&D scenarios. The mill significantly enhances ink tinting strength, gloss, and stability, meeting the stringent requirements of advanced applications.

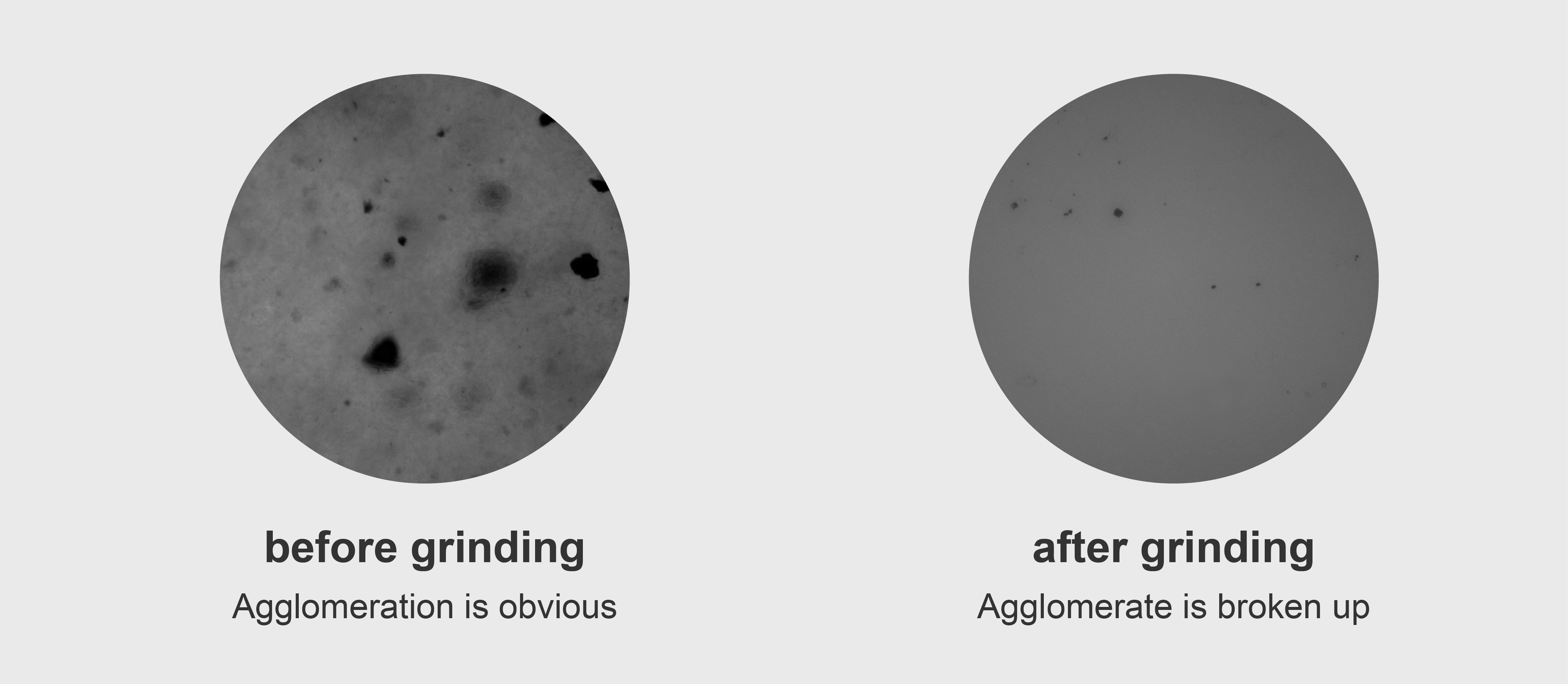

Conductive Ink Grinding and Dispersion Results

Microscopic Comparison Before and After Resin Dispersion

The microscopic images clearly demonstrate a significant deagglomeration and dispersion effect after processing with the precision triple roller mill. The grinded material exhibits greatly improved dispersibility and uniformity compared to the initial state.

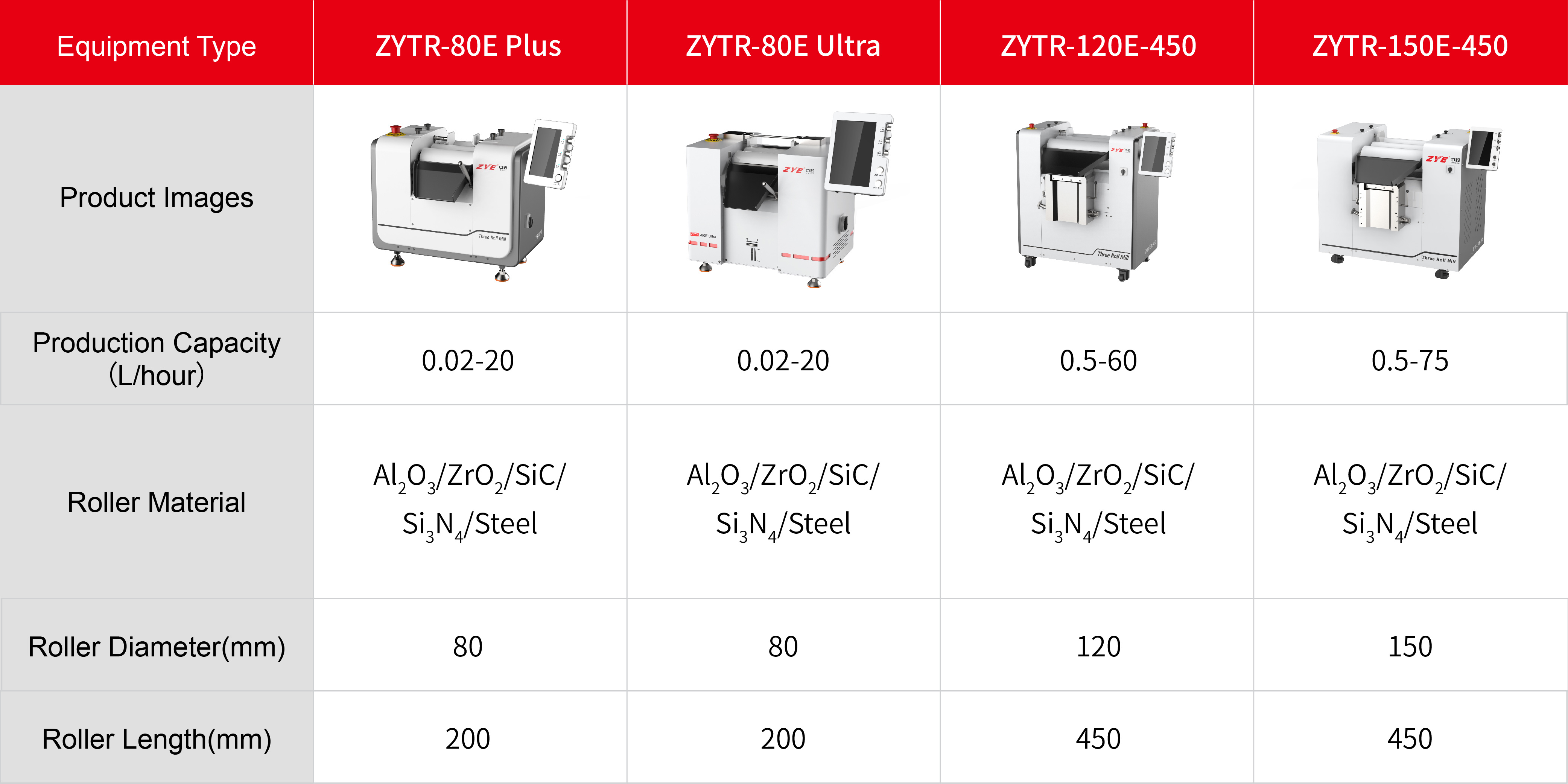

Multiple models available

Summary

The participation in the 2025 Guangzhou International Ink Industry Exhibition was not only a platform for ZYE Technology to showcase our products, but also a stage to demonstrate China's new heights in precision manufacturing to the global audience. By exhibiting advanced precision equipment, we expanded our customer base, strengthened industry exchanges, and enhanced our brand influence.

Moving forward, we will wield technological innovation as our spear and green intelligent manufacturing as our shield, continuously optimizing product performance and introducing more high-end precision equipment tailored to market demands. We will actively expand into domestic and international markets, deepen collaboration with customers and partners, and contribute even greater momentum to the high-quality development of the ink industry and related fields. Together with industry peers, we will paint an even brighter future for the sector.