Marketing Event | Spotlight On SAMPE 2025: ZYE Technology Empowers The Composites Industry With Cutting-Edge Equipment

2025-06-24 09:54

From June 18 to 20, the 20th International Exhibition for Advanced Composites, Raw Materials, Tooling & Engineering Applications (SAMPE 2025) successfully concluded at the China International Exhibition Center. At this premier industry event covering the entire supply chain, ZYE Technology, a leading Chinese manufacturer of high-end precision equipment in ultra-niche fields, showcased its independently developed solutions, including precision three-roll mills and non-invasive planetary centrifugal mixers. By demonstrating its technological expertise and exploring new industry opportunities, ZYE Technology achieved remarkable engagement and left a lasting impression on attendees.

This globally renowned industry event, spanning 7 exhibition halls and 32,000 square meters, brought together over 400 exhibitors from around the world and attracted more than 12,000 professional visitors.

As SAMPE's premium industry exhibition in mainland China for 20 consecutive years, the event focused on the full industrial chain and engineering applications of advanced composites. It covered diverse fields, including:

Digital technologies & design simulation

High-performance reinforcement materials, matrix materials, and core materials

Auxiliary materials, tooling, and processing equipment

Advanced composite structures, testing, analysis, repair, and recycling

The exhibition served as a high-quality platform for industry exchange and collaboration.

On-site, cutting-edge innovations from global industry leaders vividly demonstrated the wide-ranging applications of composite materials in aerospace, automotive manufacturing, new energy, and beyond.

Through its participation, ZYE Technology gained deep insights into the industry's growing demand for:

Ultra-precision processing equipment

Intelligent manufacturing solutions

Sustainable and eco-friendly technologies-now a driving force in R&D and production, shaping the future of the industry.

Highlights

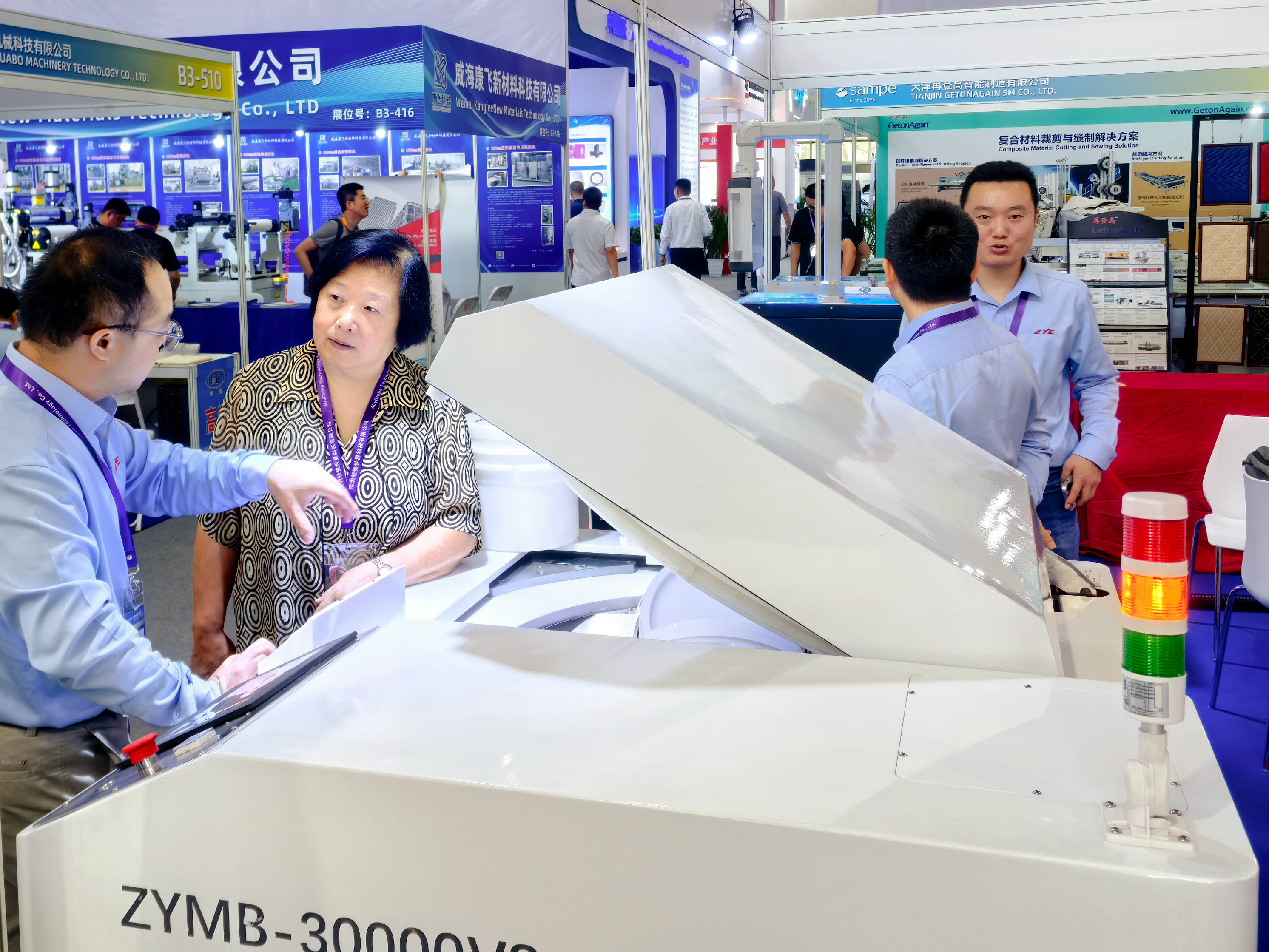

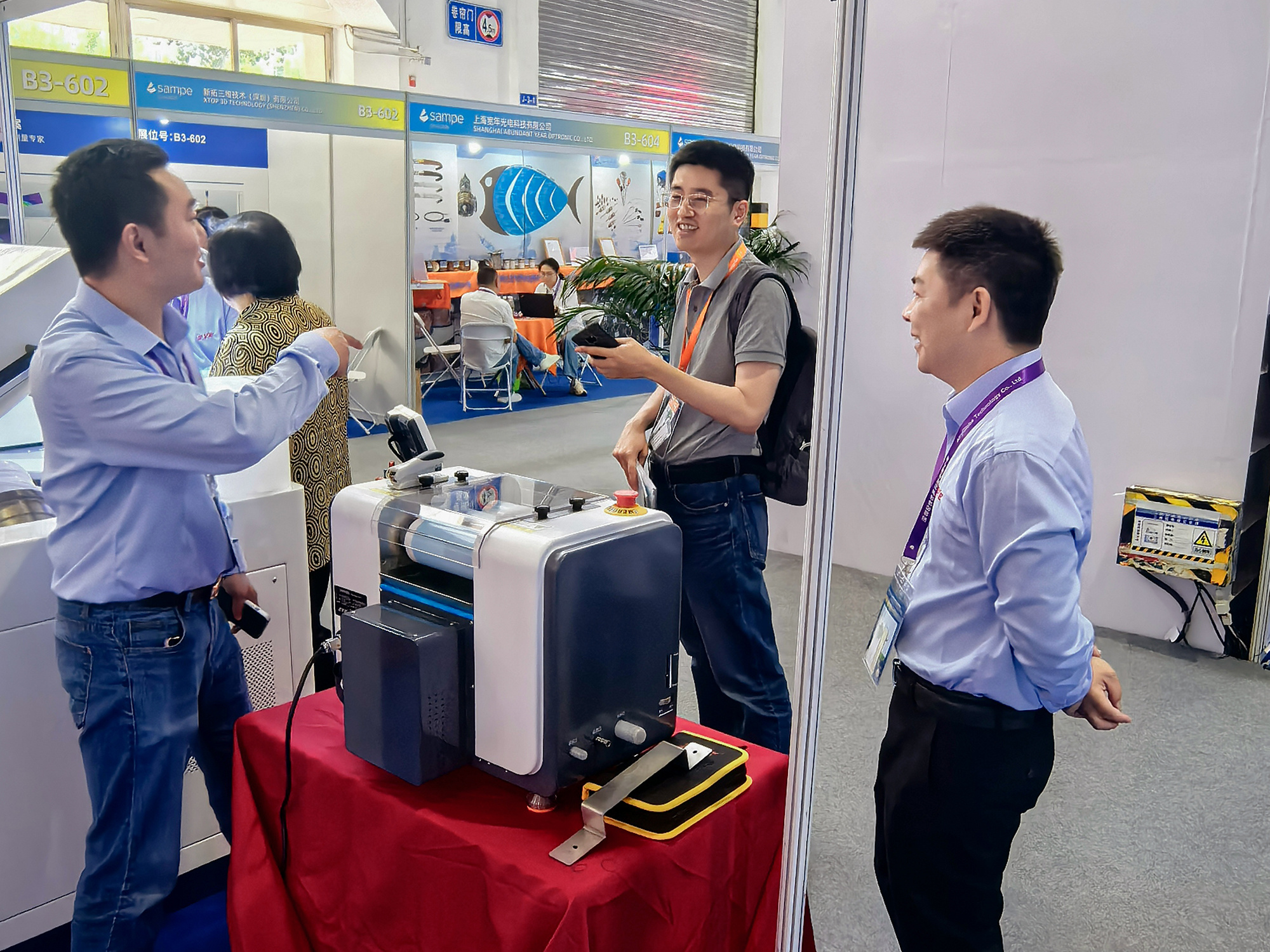

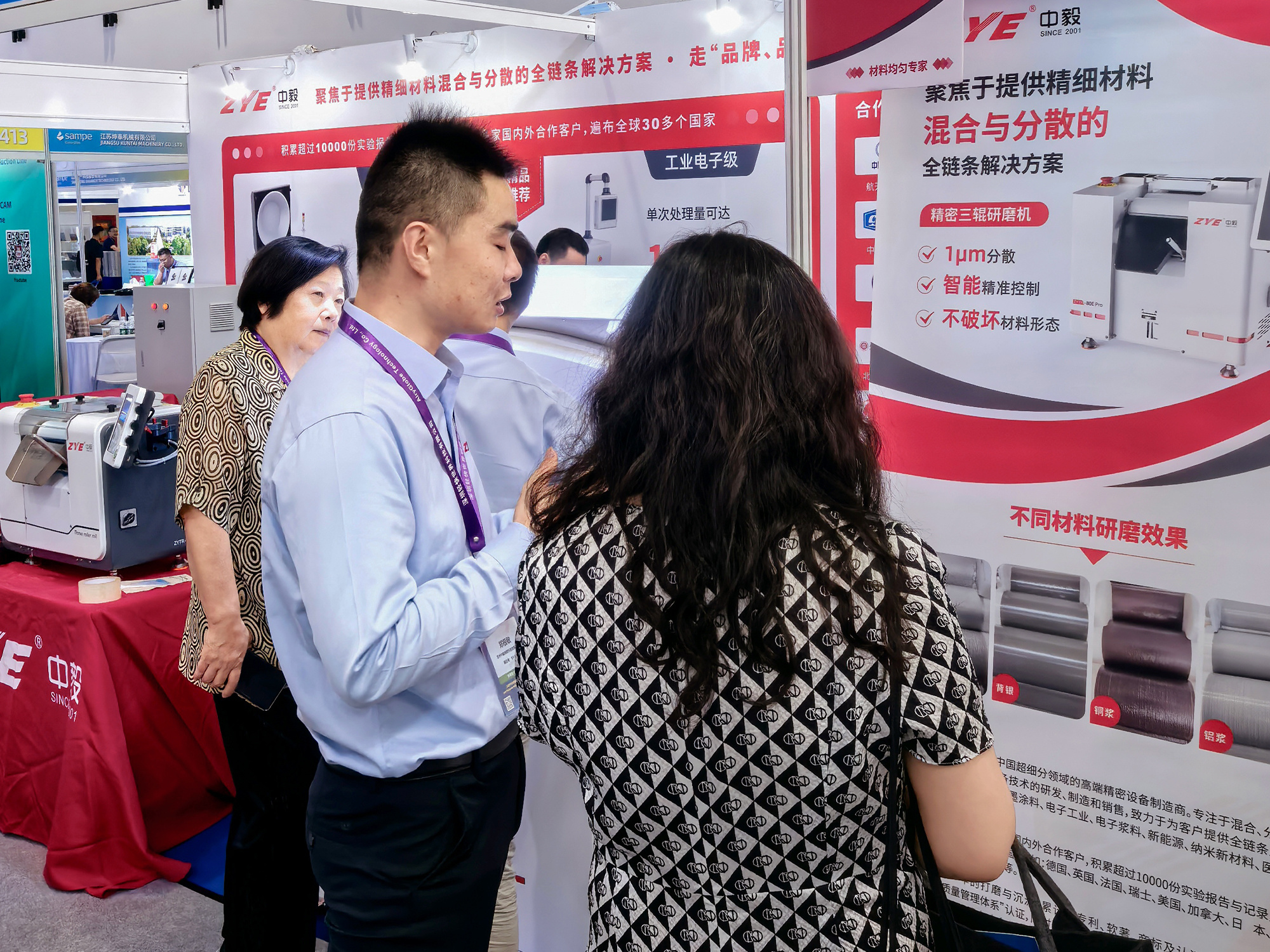

At the exhibition, ZYE Technology's independently developed precision three-roll mill and non-invasive planetary centrifugal mixer garnered widespread attention and high acclaim for their unique technological advantages and innovative features. The ZYE team demonstrated professional expertise, enthusiastic service, and in-depth industry knowledge, providing every visiting client with detailed product introductions and tailored solutions.

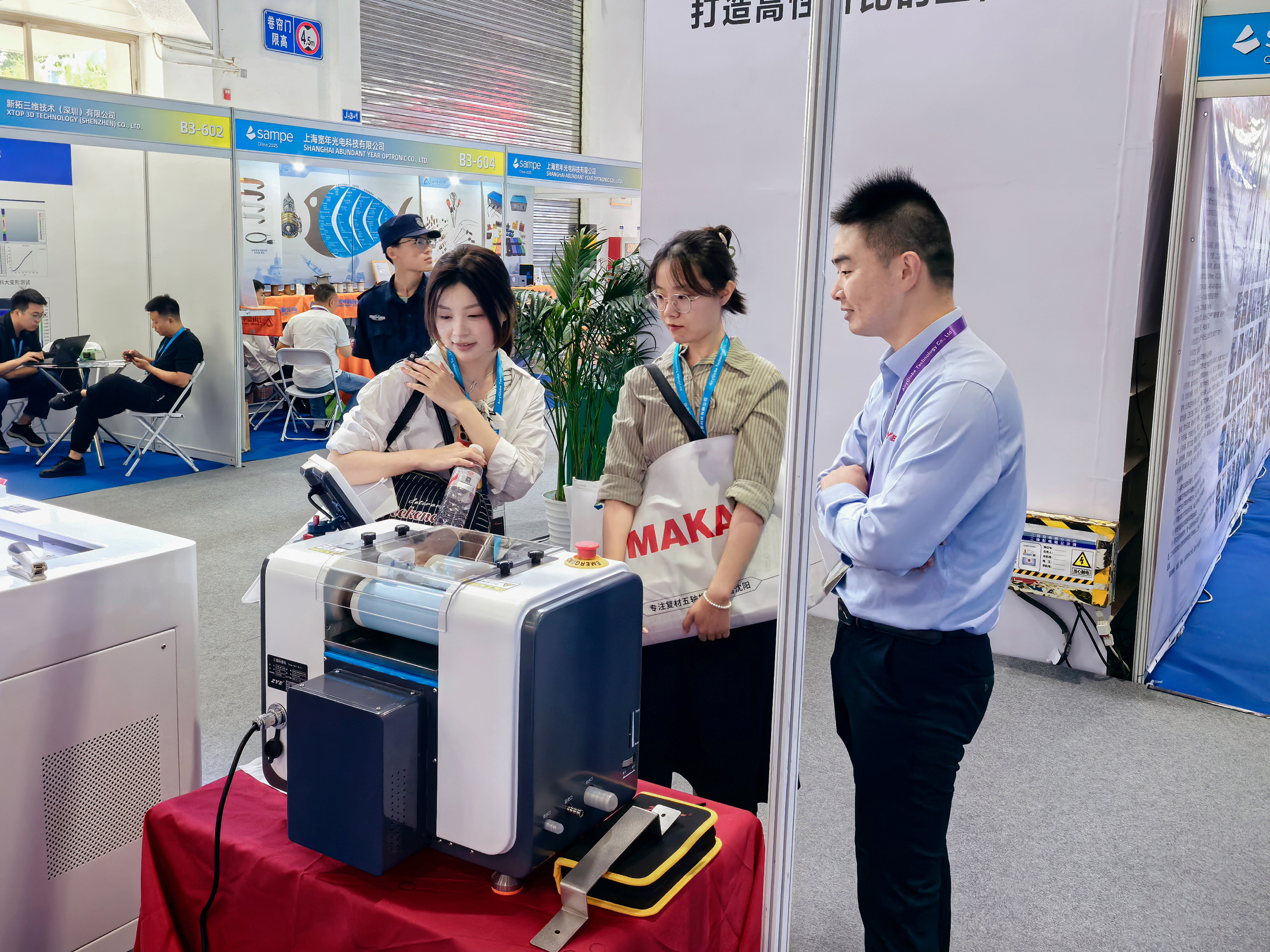

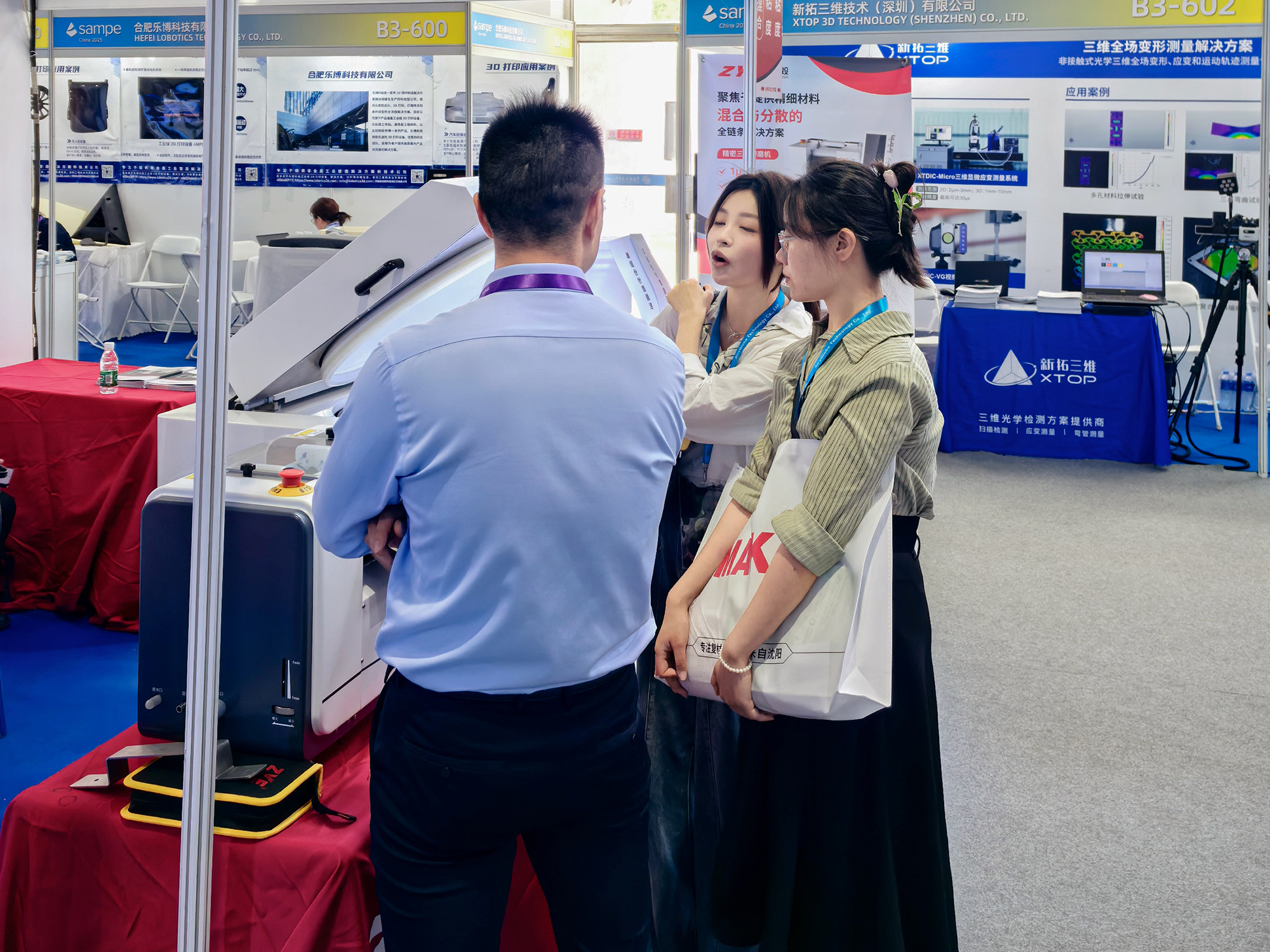

On the first day of the exhibition, a customer developed strong interest in ZYE Technology’s vacuum deaeration machine after an in-depth technical discussion with the ZYE team. The next day, the customer made a special trip to the booth, bringing a key composite material from their production line to conduct an on-site performance test of the equipment.

On-site engineer guidance

Live test video with customer’s material

This on-site test not only showcased the robust performance of ZYE products in a direct and compelling way, but also served as a vivid example of how ZYE Technology earns customer trust through technical excellence.

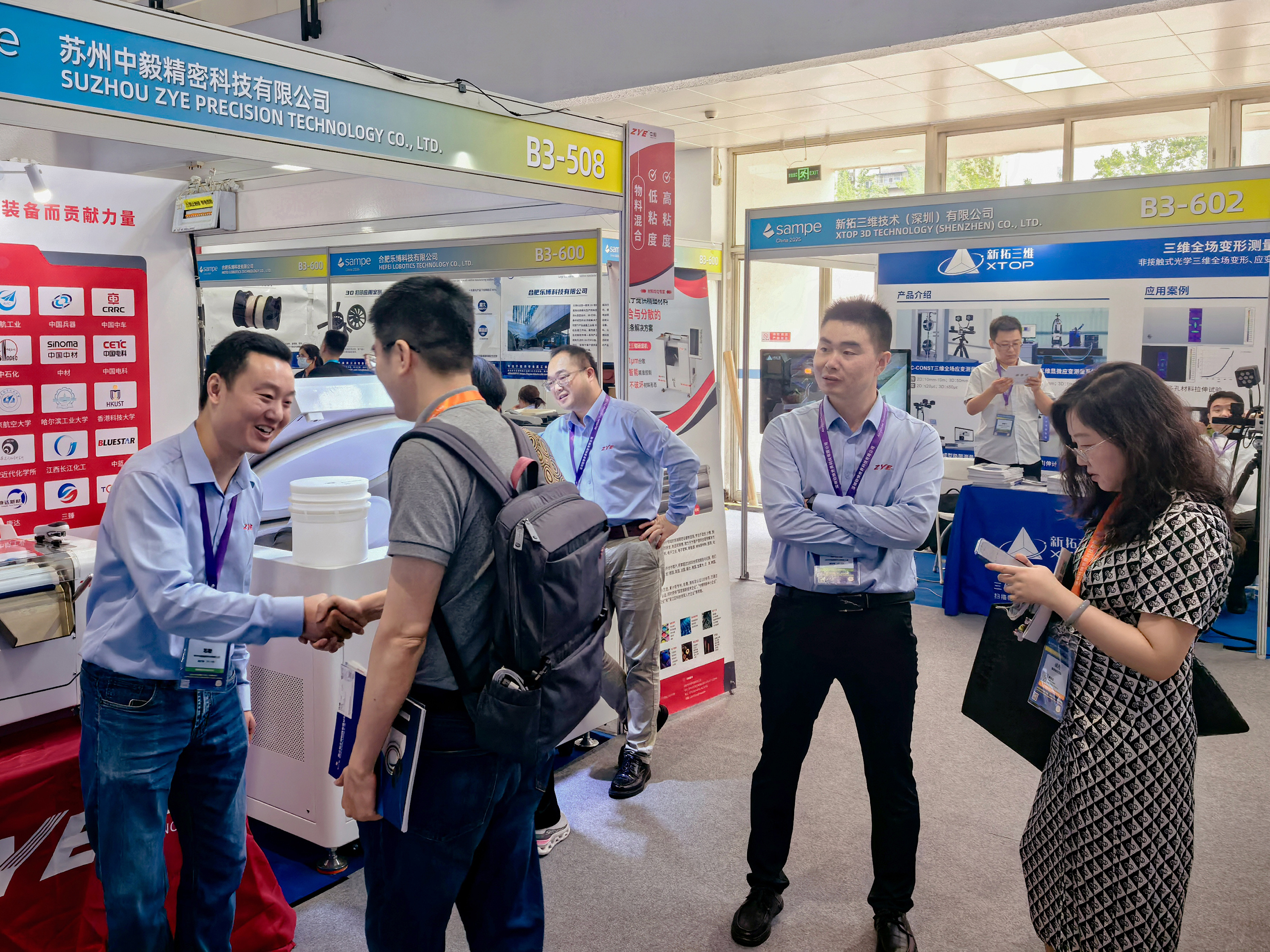

High-quality service relies on close collaboration and efficient communication among team members. From the moment the customer raised the testing request, the ZYE team responded promptly: engineers precisely tuned the equipment parameters, technical consultants provided professional explanations throughout the process, and sales representatives carefully documented customer feedback.

Each step was seamlessly coordinated and executed with efficiency, enhancing the company’s brand image while laying a solid foundation for building long-term partnerships with clients.

This exhibition served as a valuable bridge for ZYE Technology to engage directly with potential customers. Many representatives from companies seeking precision material processing equipment showed strong interest after learning about ZYE’s products and solutions, and held in-depth discussions with the ZYE team.

Technical advantages

Material performance is a key factor in the manufacturing process of basic industries, and mixing and dispersion play a central role in the preparation of high-end precision materials. The effectiveness of mixing and dispersion directly affects the properties and real-world applications of the materials.

Different mixing technologies and equipment impact the physical and chemical properties of materials—such as strength, thermal conductivity, electrical performance, and mechanical behavior. These properties ultimately determine how the materials are applied across industrial fields.

With its two flagship products—the three roll mill and the non-contact material homogenizer—ZYE Technology provides essential solutions for the industry.

01

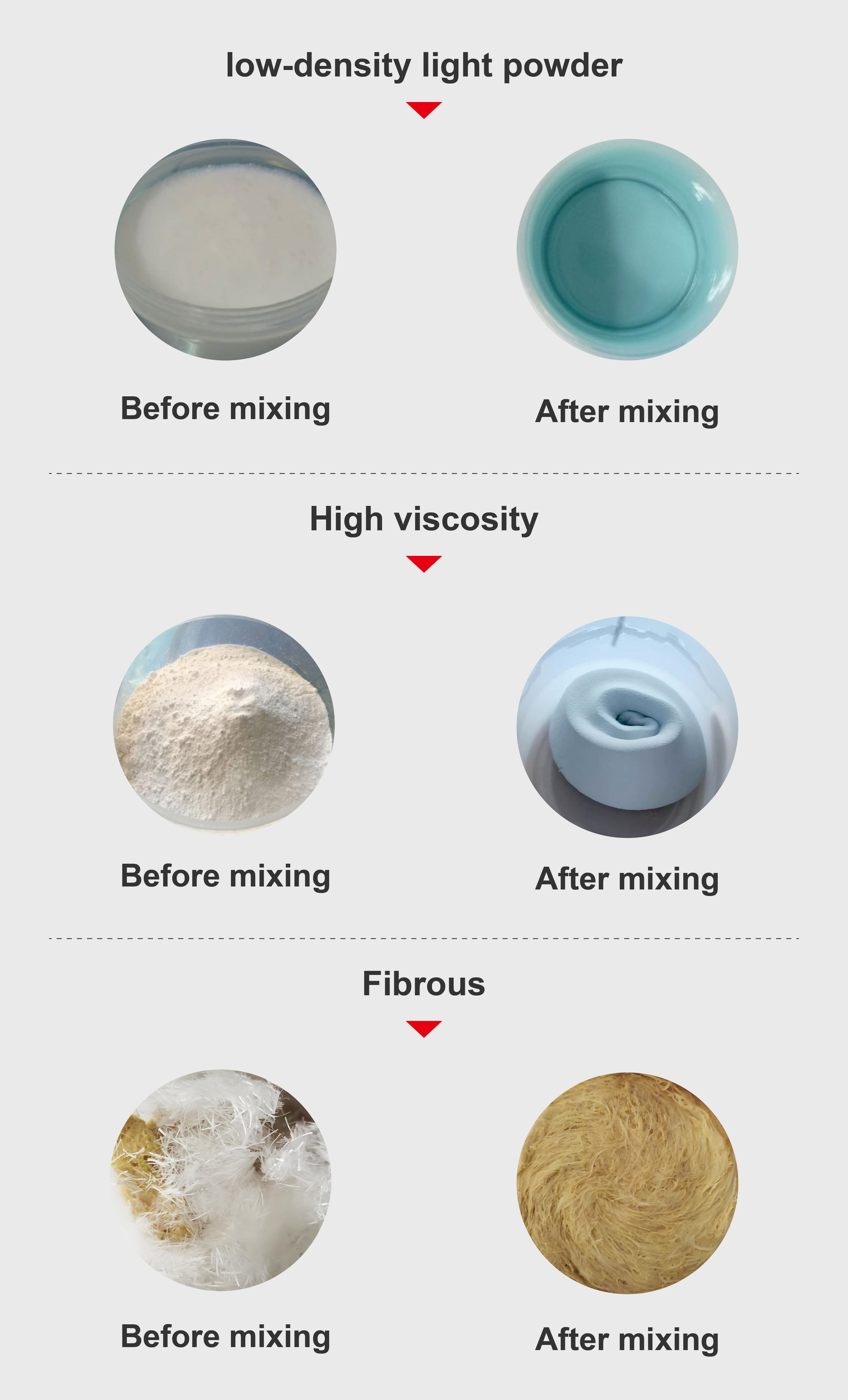

Deaeration mixer for mixing materials of varying viscosities

In the aerospace industry, it eliminates bubbles in carbon fiber composites, helping reduce component weight while enhancing structural toughness. In electronic packaging, it precisely removes bubbles from epoxy resins, establishing a reliable barrier for thermal management and electrical performance to ensure stable chip operation. During the preparation of biomedical materials, it helps prevent potential implant risks caused by trapped air. For high-energy battery slurries, its processing significantly improves coating uniformity, thereby boosting energy density and cycle life.

From lightweight aerospace components to high-density electronic packaging, from biomedical materials to advanced battery slurries, the deaeration mixer remains a core tool for eliminating material defects. It is a vital safeguard for maintaining the stability and functionality of cutting-edge materials under extreme conditions—driving technological innovation across multiple industries.

Various Materials Are Mixed By Deaerator

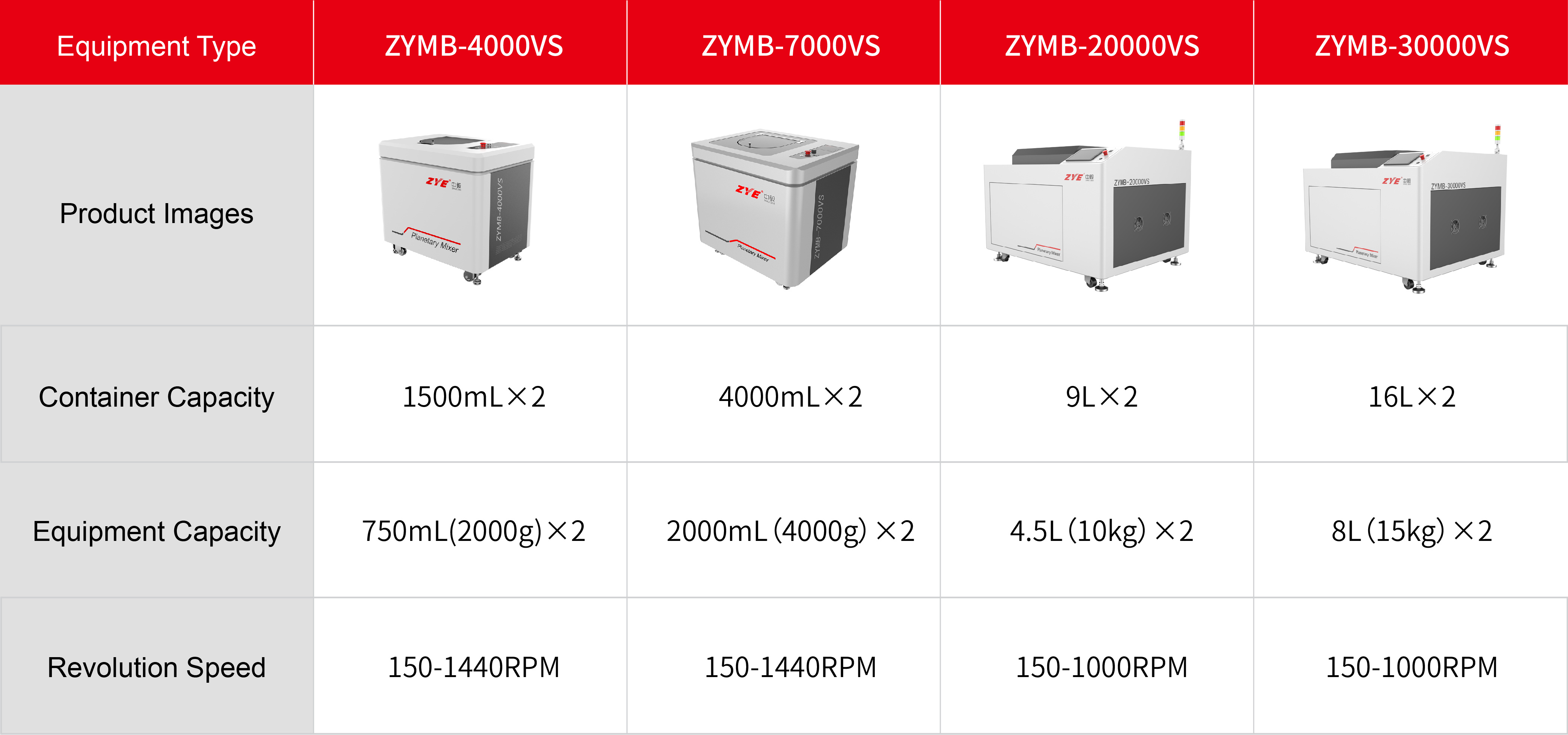

Various models available

02

Triple roller mill in Battery Materials Applications

In the production of advanced composite materials, fine processing and uniform dispersion are critical factors that determine material performance. ZYE’s precision three roll mills play a pivotal role in this field with their outstanding technical capabilities.

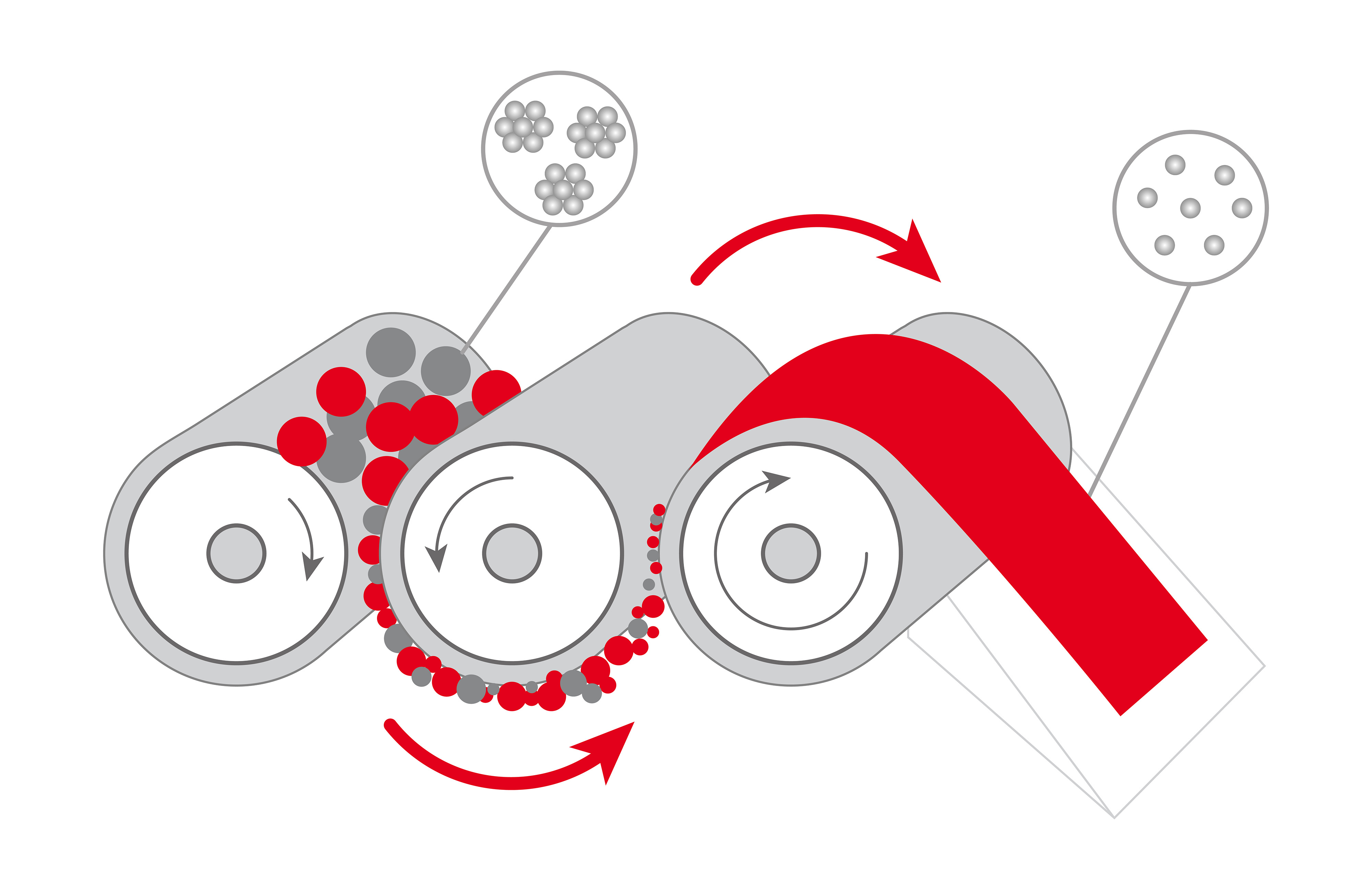

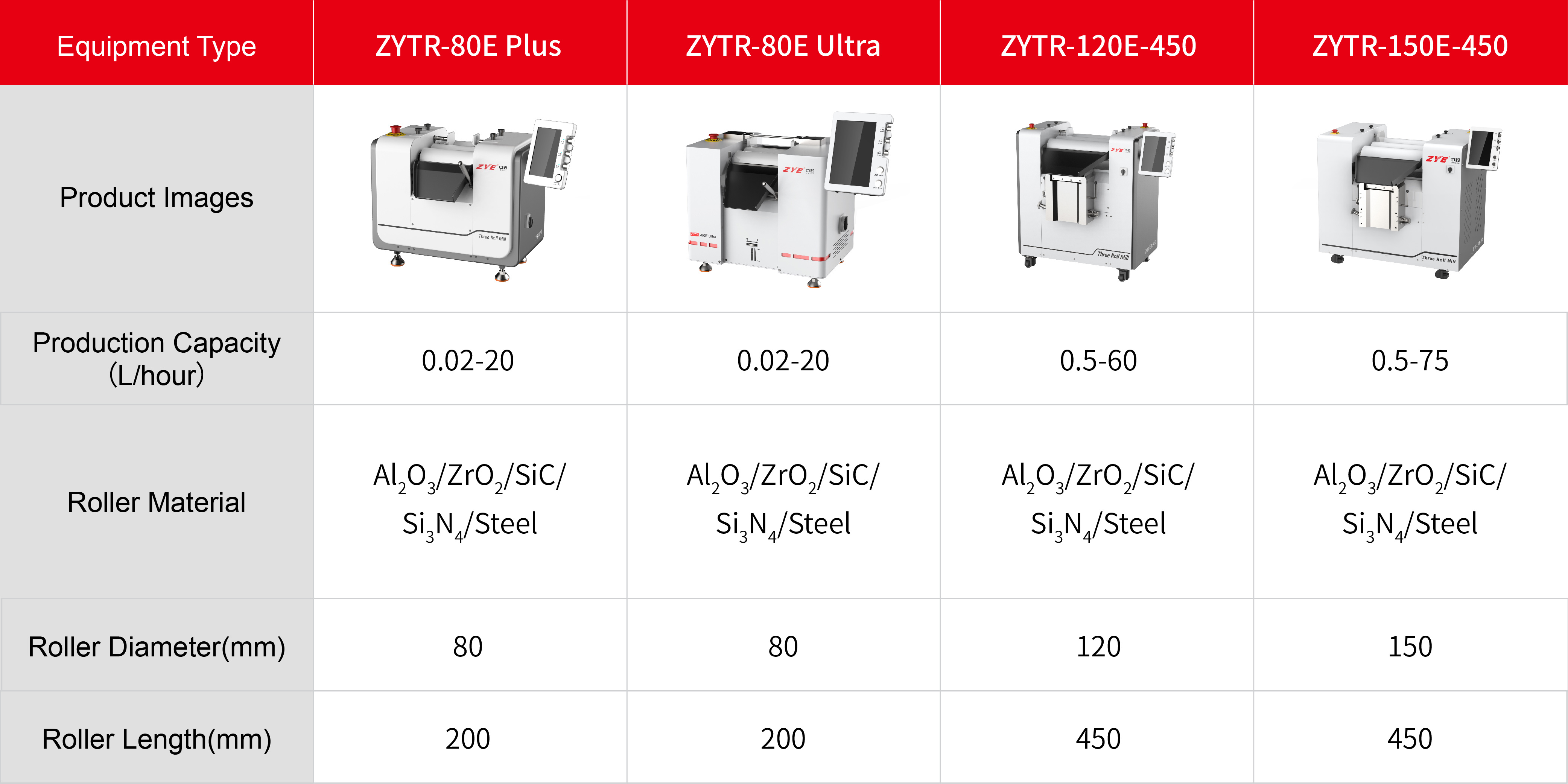

ZYE’s three roll mill is a high-precision model, recognized as one of the most effective dispersion solutions for medium- to high-viscosity materials. It achieves submicron-level fine dispersion while ensuring optimal particle size distribution. Widely used in the manufacturing of advanced composites across cutting-edge industries, its core principle lies in the application of shear force generated by three horizontally aligned rollers rotating at different speeds and directions.

With ZYE’s precise gap control technology, the machine achieves efficient deagglomeration without damaging the surface morphology of the materials—ensuring both performance and integrity during processing.

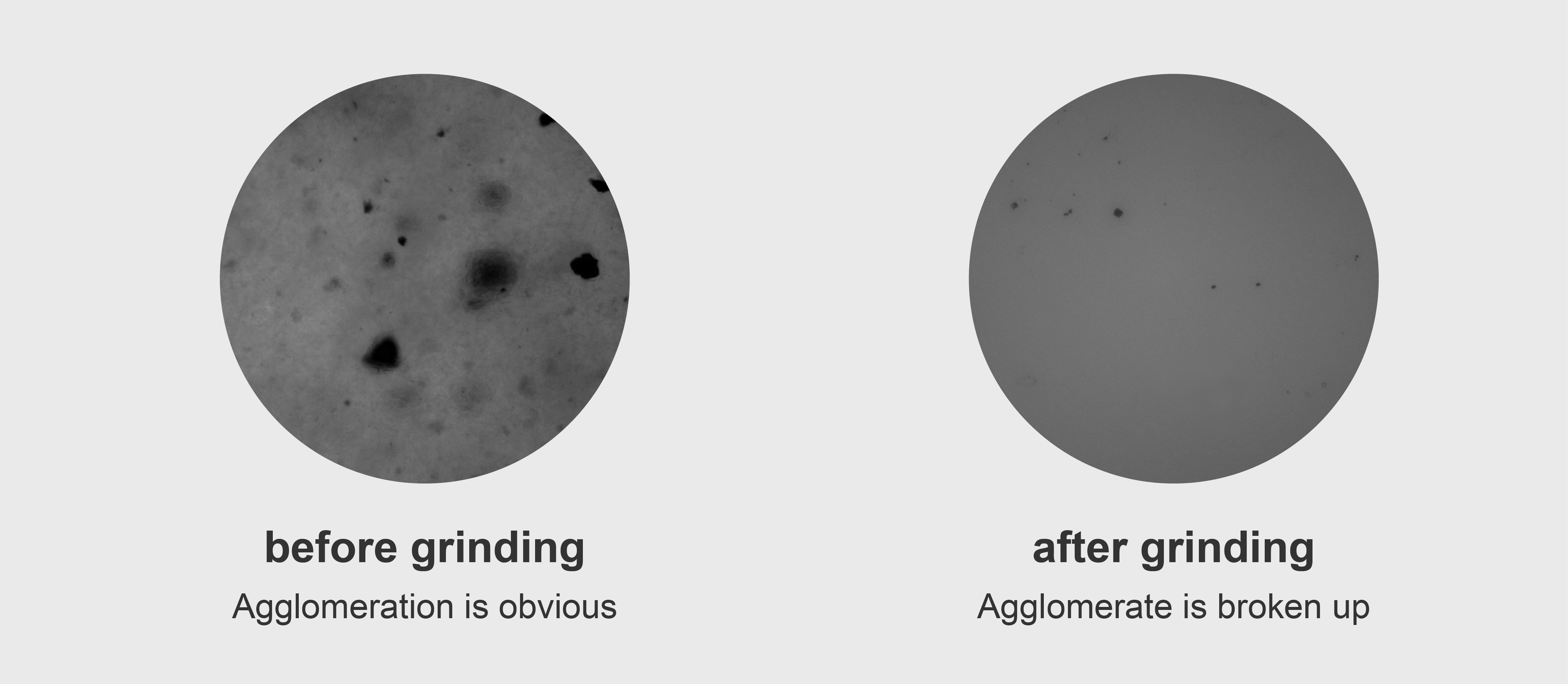

Microscopic Comparison Before and After Resin Dispersion

The microscopic images clearly demonstrate a significant deagglomeration and dispersion effect after processing with the precision triple roller mill. The grinded material exhibits greatly improved dispersibility and uniformity compared to the initial state.

Multiple models available

Meeting Summary

At the 20th SAMPE 2025 Exhibition, ZYE Technology Achieved Remarkable Results in Showcasing Technical Strength and Expanding Industry Collaboration

At the 20th SAMPE 2025 Exhibition, ZYE Technology made significant achievements in demonstrating its technological capabilities and expanding industry communication and cooperation. Looking ahead, ZYE Technology will continue to focus on innovation in material dispersion technology, increase R&D investment, and enhance product performance and quality. The company is committed to providing customers with higher-quality, more efficient precision material processing equipment and solutions.

In parallel, ZYE will closely follow industry development trends and evolving customer needs, continuously optimizing its strategic planning and business direction. The company will deepen collaborative innovation with customers and partners to jointly promote technological advancement and development within the advanced composite materials industry. These efforts are key to achieving ZYE’s long-term development goals.

With the concerted efforts of all employees, ZYE Technology is confident in achieving even greater success in future market competition and contributing more significantly to the development of China's high-end precision equipment manufacturing sector.

About ZYE Technology

Founded in 2007, ZYE Technology is a leading high-end precision equipment manufacturer in China's ultra-niche sectors. We specialize in the research, development, manufacturing, and sales of technologies for mixing, dispersion, deaeration, filling, coating, and inspection preparation. Dedicated to providing customers with full-process solutions, our technologies are widely applied in adhesives, inks and coatings, electronics, electronic pastes, new energy, nanomaterials, pharmaceuticals, cosmetics, and other industries.

To date, we have served more than 2,000 domestic and international clients, with over 10,000 experimental reports and records accumulated. Our equipment has been exported to more than 30 countries and regions, including Germany, the United Kingdom, France, Switzerland, the United States, Canada, Japan, South Korea, Israel, Singapore, Malaysia, and more.

After nearly 17 years of continuous refinement and innovation, ZYE has obtained over 100 intellectual property rights, including patents, software copyrights, trademarks, and certifications. We are ISO 9001 Quality Management System certified, and have been honored as a "National High-Tech Enterprise," a "Specialized and Innovative SME," a "Suzhou Leading Talent Enterprise," and a "Wujiang District Technology Talent Enterprise."

ZYE is committed to customer-centric applications and a culture of driven innovation. We are building a premium brand in the precision equipment industry and pursuing a path of "brand and quality" to contribute to the advancement of China’s high-end manufacturing sector.