From Lab To Mass Production: How Three-Roll Mills Help New Materials R&D Firms Overcome The “Pilot-Scale Trap”

2025-07-15 15:37

In the field of new materials R&D, the transition from laboratory research to large-scale production is fraught with challenges-the "pilot-scale trap" being one of the most difficult. The pilot stage bridges the gap between small-scale lab results and industrial production, requiring scale-up validation and process optimization. Many companies fail at this stage-not due to flawed technology, but because they cannot consistently achieve efficient, stable, and cost-effective production processes. The ZYE three-roll mill, thanks to its unique operating mechanism and performance advantages, has become a powerful tool to help firms overcome this trap.

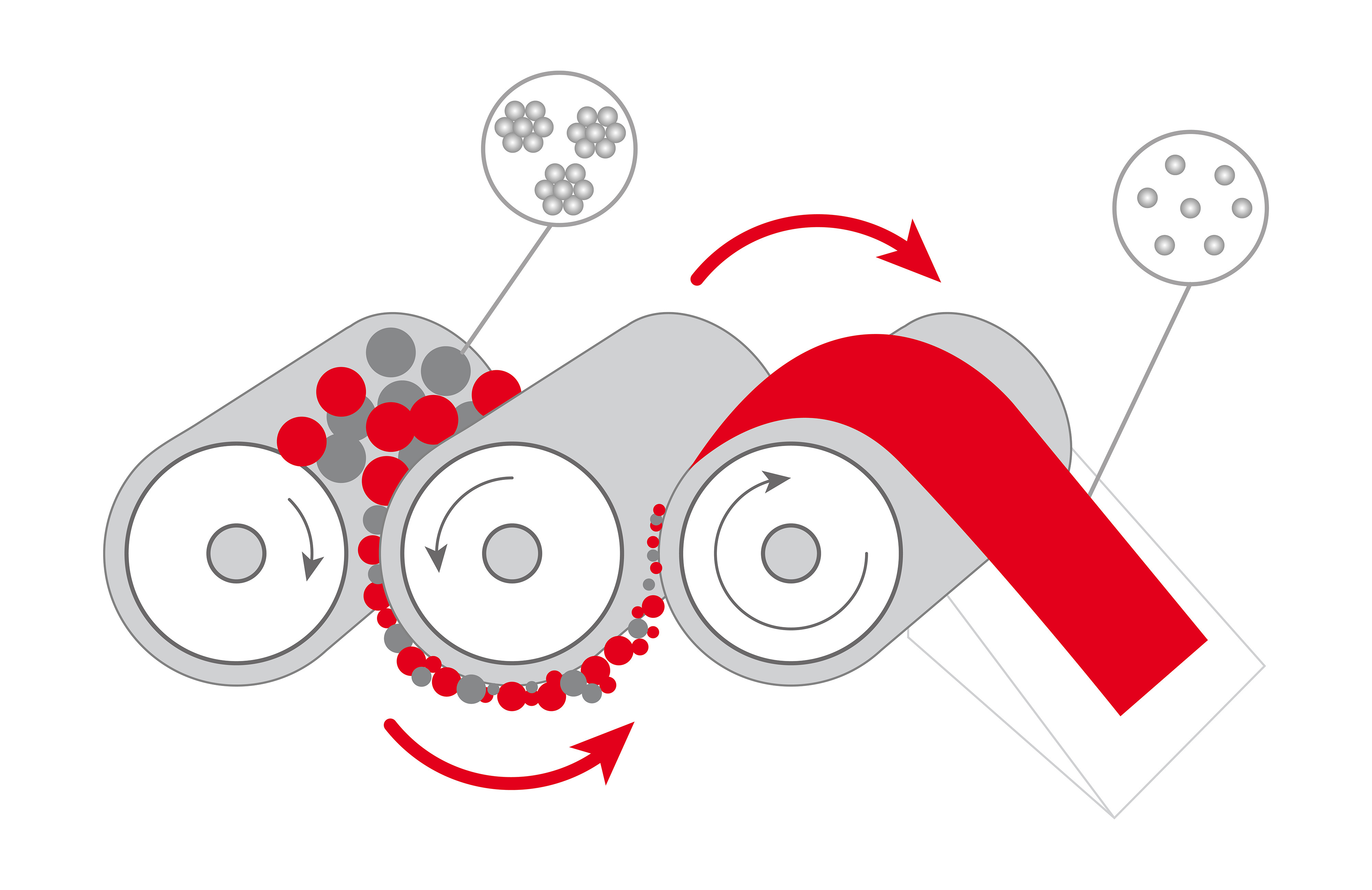

Precise Dispersion And Grinding Ensure Material Consistency

During lab-scale R&D of new materials, ensuring uniform dispersion of components and fine grinding is crucial. For instance, when developing nanoscale composite materials such as graphene-reinforced polymers, the even dispersion of graphene layers directly determines mechanical and electrical properties. A three-roll mill uses three rotating rollers with different surface speeds to generate shear and compressive forces, achieving uniform dispersion of graphene nanosheets within the polymer matrix. With micron-level adjustable roller gaps, it provides precise, small-batch processing to ensure lab samples are consistent-laying a stable foundation for pilot-scale and mass production.

Flexible Process Adjustment Adapts To Diverse Material Characteristics.

New R&D materials vary widely in viscosity, hardness, and other properties. The three-roll mill offers high flexibility: operators can adjust roller speed, pressure, and feed rate based on material traits. For example, with high-viscosity ceramic slurries that require strict particle size distribution control, adjusting roller speed ensures the right shear force to break aggregates without damaging particles. Precise pressure control ensures desired grinding and dispersion when passing through roller gaps-tailoring performance to specific slurry demands.

Stable Scale-Up Ensures Consistent Quality

One core challenge in scaling up from pilot to mass production is maintaining product consistency. ZYE's small-batch production three-roll mill enables a scalable and stable process. Firms can increase equipment size and use precision automation to control roller speed ratios, pressure, and feed rate-ensuring, for instance, in paint production that pigments and resins remain uniformly dispersed in larger batches. Consistent color, gloss, and adhesion across batches lay a solid foundation for mass production.

Improve Production Efficiency To Meet Capacity Needs

Pilot-scale trials must demonstrate process efficiency to meet future volume demands. Three-roll mills offer high throughput via continuous processing. In battery electrode slurry production, they allow ongoing dispersion and grinding, significantly accelerating production versus batch systems. Optimized rollers and feed/discharge design further increase throughput-supporting the lithium battery industry's urgent demands and helping firms meet pilot-scale efficiency goals.

Lower Production Cost To Enhance Feasibility

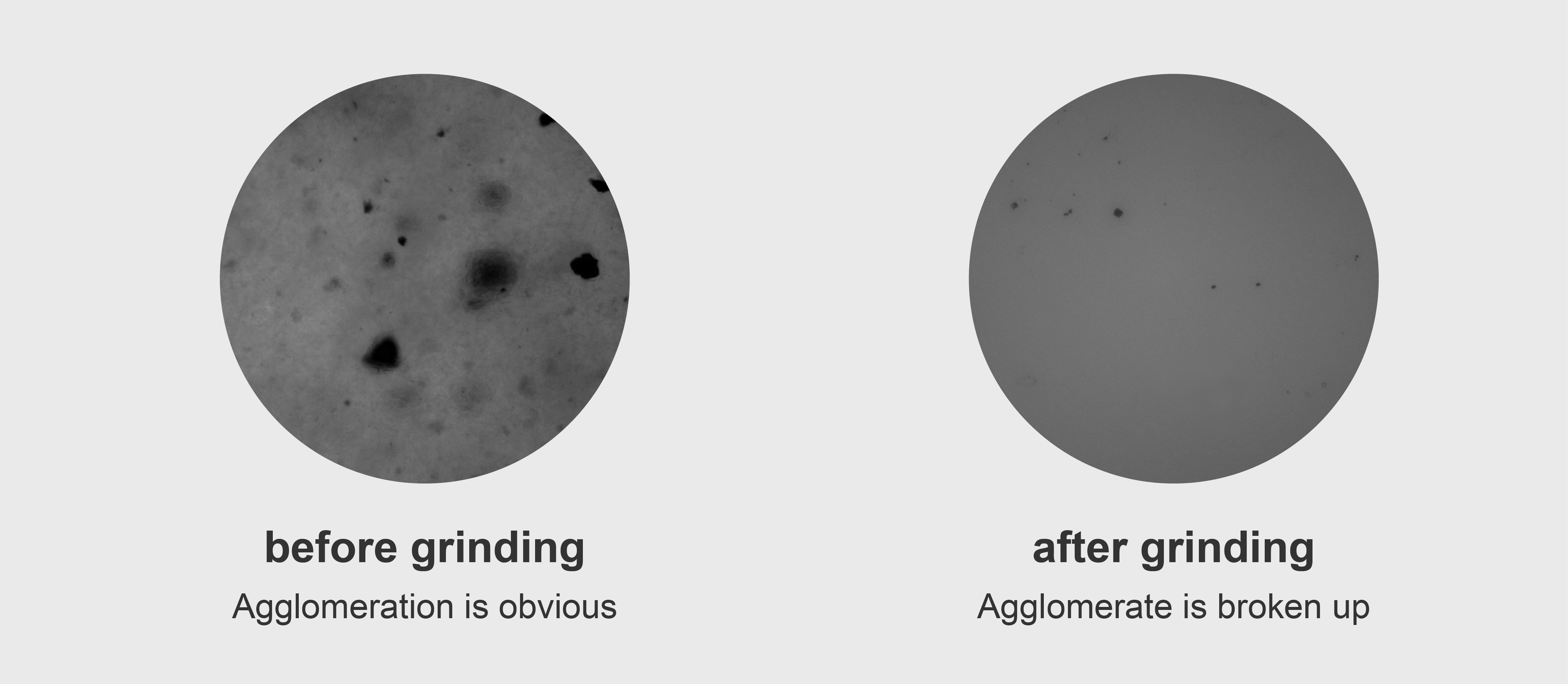

Cost control is a critical factor in pilot-scale viability. Three-roll mills help reduce costs in two ways: (1) their efficiency cuts per-unit production time, lowering labor and energy costs; (2) precise process control reduces material waste. In magnetic material trials, uniform dispersion minimizes particle aggregation-preventing defects, reducing rework, and boosting material use efficiency. Together, they enhance economic viability and make scale-up more feasible.

Comparison Under Microscope Before And After Resin Dispersion

In mass production, long-term equipment stability is paramount. ZYE Zhongyi three-roll mills feature easy-to-clean rollers with high structural stability and minimal deformation. Key structural parts use specialized sintering techniques for high density. Dual-bearing designs eliminate clearance and vibration-enhancing grinding precision and operational reliability. With production rates up to 100 L/h, and fully automated system integration, the mill ensures consistent product quality while dramatically increasing throughput to meet large-scale demand.

Crossing the "lab-to-mass-production" pilot-scale trap is no easy feat for new material R&D firms. Across stages-from precise lab-scale exploration, pilot-scale breakthrough, to mass production stability-ZYE three-roll mills play an indispensable role in dispersion, scale-up, cost control, and process integration. Their full-series solutions support the smooth transition from research to production and drive the thriving development of the new materials industry.