Quality-Driven, Innovation-Led: ZYE and Hanfang New Materials Unlock New Heights in the High-End Adhesive Industry

2025-07-28 15:31

In today’s era of rapid technological advancement, adhesives have become an indispensable auxiliary material in modern industries—from chip packaging and new energy vehicles to medical devices and aerospace applications. Their unique bonding properties provide strong support for technological progress across diverse sectors. Behind the scenes, the development and manufacturing of high-end adhesives—along with the support of precision equipment—are fundamental. As high-end adhesives become a benchmark for industrial strength, the deep collaboration between ZYE Technology and Hanfang New Materials Technology (Jiashan) Co., Ltd. is redefining performance benchmarks with a shared vision: “Quality First, Win-Win Cooperation.”

The Hidden Code Behind Industrial Upgrades

High-end adhesive development is a dual challenge involving formulation innovation and process equipment precision. In the semiconductor industry, adhesives must meet stringent requirements like conductivity, thermal management, and extreme temperature resistance to ensure chip reliability in micro-scale environments. In the EV sector, adhesives play critical roles in battery pack sealing, module fixation, and thermal dissipation—directly impacting vehicle range and safety. In electronics manufacturing, the uniformity and strength of adhesives influence everything from screen flatness to structural reliability and overall product lifespan.

As an industry innovator, Hanfang New Materials focuses on developing high-performance industrial adhesives and promoting sustainable solutions. Their product portfolio includes Conductive Die Attach Paste (CDAP), Conductive Die Attach Film (CDAF), Non-Conductive Adhesive Film (DAF), and high thermal-conductivity sintering materials (copper and silver sintering). These materials are widely used and well-recognized across semiconductor packaging, display panels, consumer electronics, and automotive electronics industries.

Rising Challenges and the Need for Domestic Breakthroughs

Despite increasing demand, the adhesive industry faces many challenges. International competitors maintain a lead through decades of R&D and brand strength. In contrast, the domestic market is fragmented, with low industry concentration and high technological barriers. Especially in the field of semiconductor adhesives, extreme precision and high-level expertise have become entry barriers for many companies.

To produce world-class adhesives capable of competing globally, advanced equipment is essential. ZYE Technology understands this deeply. Since its founding in 2007, the company has focused on mixing, dispersing, deaeration, filling, coating, and inspection technologies—offering end-to-end solutions to help clients overcome technical hurdles and accelerate industrial breakthroughs.

Measuring Progress with Micron-Level Equipment Precision

In Hanfang’s adhesive production line, ZYE’s three roll mill and vacuum deaerator serve as the backbone of quality assurance.

🔹 Precision Three Roll Mill: The Powerhouse of Dispersion

ZYE’s precision three roll mill is a game-changer for dispersing viscous adhesive materials. It uses three horizontally aligned rollers with different speeds and rotational directions to generate intense shear forces. This ensures precise grinding, dispersing, and homogenizing of sticky compounds. The result? Enhanced particle size distribution and uniform dispersion of all adhesive components.

More importantly, the system addresses the stability of micron-level gap control. With automated roller gap calibration, each operation maintains consistent spacing and temperature control—ensuring uniform product quality. Thanks to this equipment, Hanfang’s adhesives have achieved a new standard in uniformity and performance.

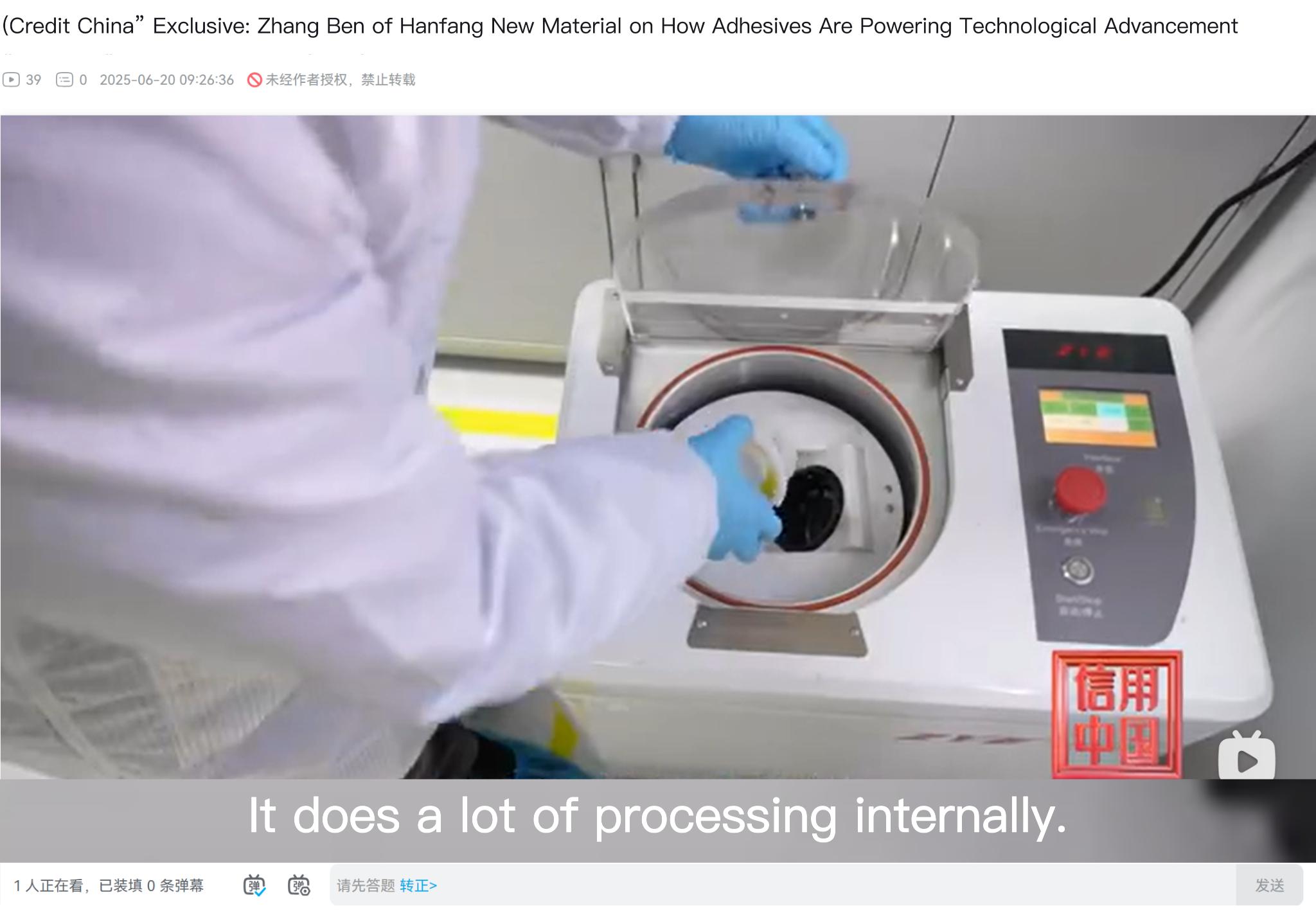

🔹 Vacuum Planetary Mixer: The Bubble-Free Solution

In adhesive processing, bubbles can be a serious performance killer, causing weak bonding and uneven coverage. ZYE’s vacuum planetary mixer, also known as a non-contact homogenizer, uses centrifugal force to push trapped air to the material surface. A high-vacuum environment then removes these bubbles completely, while an internal cooling system circulates air to dissipate heat caused by mixing friction. This prevents material degradation, enhances mixing efficiency, and extends pot life. With this technology, Hanfang significantly reduces bubble-related defects, ensuring premium product quality.

Win-Win Partnerships Drive Industry Upgrades

In the adhesive industry’s transformation toward high-end manufacturing, material innovation and equipment evolution go hand in hand. The collaboration between ZYE and Hanfang New Materials exemplifies a perfect synergy between technology providers and end users. ZYE’s professional-grade equipment offers Hanfang the stability and precision it needs for R&D and mass production. In return, Hanfang’s evolving requirements help guide ZYE’s technological roadmap—driving mutual growth.

Looking ahead, ZYE will continue to pursue innovation in precision equipment, enhancing performance and technological capabilities. The company is committed to providing reliable, high-performance solutions to forward-looking partners like Hanfang. Together, they aim to raise the competitiveness of China’s adhesive industry and respond effectively to global competition. ZYE will continue exploring new possibilities in green and sustainable manufacturing, setting a new standard in high-end adhesive development.

About ZYE Technology

Founded in 2007, ZYE Technology is a high-end precision equipment manufacturer based in China. The company specializes in the R&D, production, and sales of equipment for mixing, dispersing, deaerating, filling, coating, and quality inspection. Its technologies are widely used across industries such as adhesives, inks and coatings, electronics, electronic pastes, new energy, nanomaterials, pharmaceuticals, and cosmetics.

ZYE serves over 2,000 domestic and international clients and has accumulated more than 10,000 experimental reports and case records. Its equipment has been deployed in 30+ countries, including Germany, the UK, France, Switzerland, the U.S., Canada, Japan, South Korea, Israel, Singapore, and Malaysia.

After nearly 17 years of development, ZYE has earned over 100 patents, software copyrights, trademarks, and certifications. The company is ISO9001-certified and recognized as a National High-Tech Enterprise, a “Specialized, Refined, Differentiated and Innovative SME,” a “Suzhou Innovation & Talent Enterprise,” and a “Wujiang District Science & Technology Leader Enterprise.”

ZYE remains committed to a customer-centric, innovation-driven strategy—aiming to build a global high-end brand and contribute to the development of China’s intelligent manufacturing.

ZYE Product Highlights

① Vacuum Planetary Mixer

Also known as a non-contact homogenizing mixer, ZYE’s vacuum planetary mixing machine is based on planetary centrifugal motion. It uses a gear-driven planetary structure, motion control cards, and uneven-speed oscillation software to drive uniform material mixing and air bubble removal. The machine also integrates temperature control, stirring, deaeration, and temperature monitoring—significantly improving material processing efficiency and quality.

② Precision Three Roll Mill

ZYE’s precision three roll mill is designed for dispersing agglomerates in high-viscosity materials. It uses three horizontally aligned rollers with different speeds and directions to apply shear force, achieving fine dispersion and consistent particle size distribution. The equipment features automated roller gap adjustment, real-time dispersion pressure monitoring, data traceability, and temperature control—all of which help optimize performance and ensure material quality in critical applications.