ZYE Three Roll Mill - Pressure Curve + Industry 4.0 Functions: Giving Every Batch of Slurry a Unique “Data ID”

2025-08-13 15:26

On the frontline of precision material manufacturing, even subtle fluctuations in slurry quality can lead to significant differences in product performance. Are you troubled by these persistent issues: despite using the same formula, product quality fluctuates drastically across different shifts? Unexpected impurities appear in the slurry, costing days of investigation yet yielding no results? After months of training, new employees still struggle to fine-tune key parameters?

In many industries, the uniformity and stability of slurry play a decisive role in determining product performance. For example, in the new energy battery industry, the quality of electrode slurry directly affects charging and discharging efficiency, cycle life, and safety. Under the booming development of electric vehicles, even slight improvements in battery performance may become the key to breakthroughs in driving range and power output. In the electronic adhesives sector, the uniform dispersion of conductive particles influences the conductivity of electronic products, which in turn impacts signal transmission stability and service life. In the high-end cosmetics industry, the evenness of pigments determines whether colors appear natural and long-lasting, directly shaping consumer experience and brand reputation.

It is evident that the precision of grinding and dispersion processes is the core key to controlling product quality in these industries. ZYE three roll mills, with their advanced pressure curve and Industry 4.0 functions, provide a comprehensive, one-stop solution to these long-standing challenges.

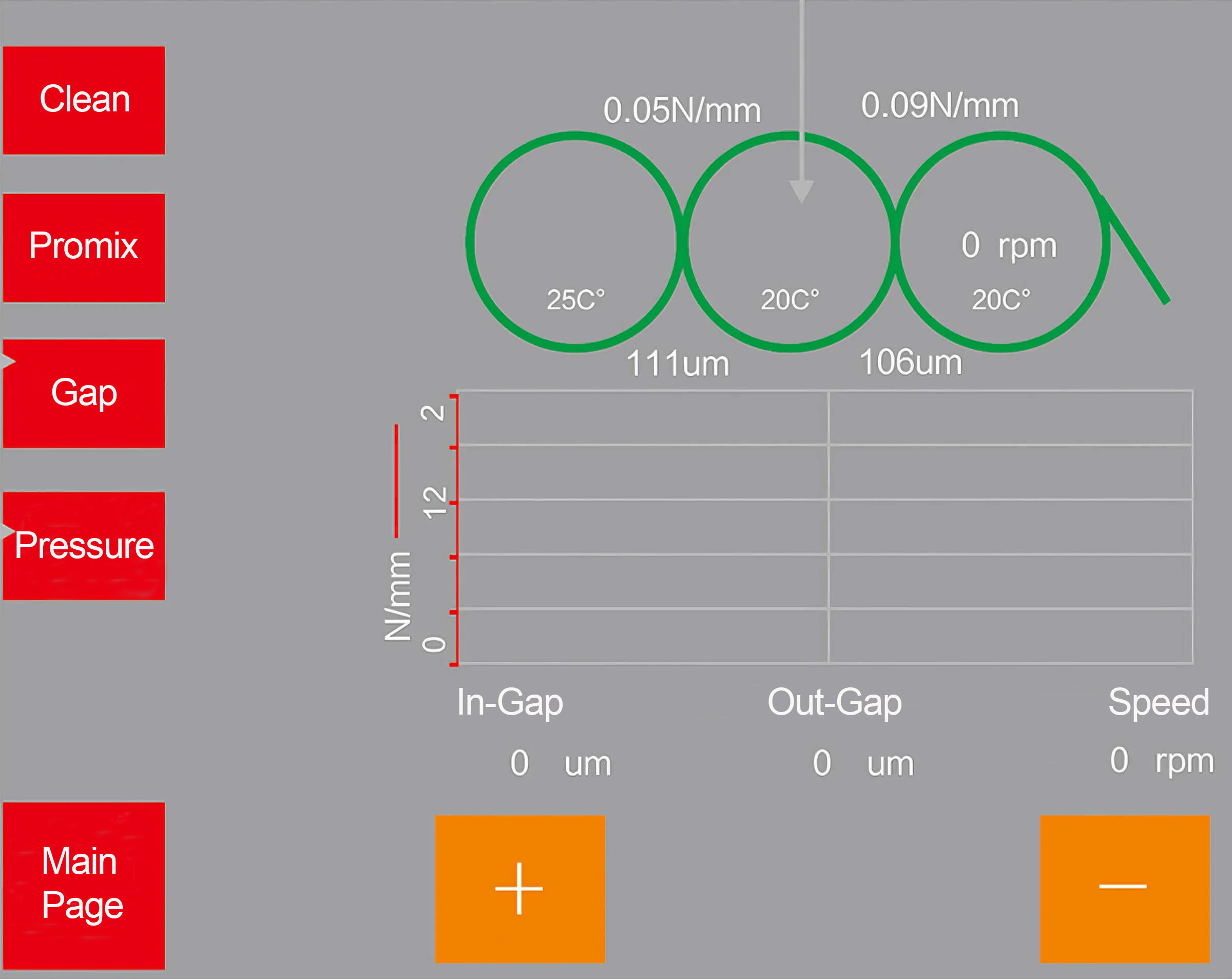

Real-Time Insight, Precision Grinding

With its advanced pressure curve technology, ZYE three roll mills function like a pair of “X-ray eyes” for the dispersion process. During grinding and dispersion, they can accurately monitor pressure changes in real time. Through in-depth analysis of pressure data, users can directly evaluate the uniformity of the material. This innovative capability completely eliminates the old approach of relying on workers’ “hand feel” and guesswork, elevating the grinding process to an entirely new level of precision and digitalization.

Intelligent Alerts, Preventing Risks Early

ZYE three roll mills transmit key process data in real time, including gap, pressure, speed, time, and roller temperature. If pressure suddenly rises or the curve shows an abnormal drop, the system immediately sends intelligent alerts, helping users accurately determine whether foreign matter has entered or if over-grinding has occurred. This not only significantly reduces material scrap rates and avoids production failures, but also saves companies from the high costs associated with quality issues.

Data Traceability, Quality Assurance

ZYE three roll mills feature powerful data traceability functions. Every grinding and dispersion record is fully stored, giving each batch of product a unique digital data ID. When a quality issue arises, users can instantly trace the root cause - whether it stems from raw material batch differences, equipment irregularities, or operational errors. From now on, when facing customer complaints, enterprises can respond with clear and accurate data support, eliminating disputes and greatly improving both quality management and customer satisfaction.

Reshaping the Logic of Precision Manufacturing

The pressure curve function of ZYE three roll mills is far more than just a technical upgrade - it represents a profound reconstruction of the underlying logic of precision manufacturing. It transforms traditional “experience-based” production into precise “data-driven” processes, helping companies achieve transparent operations, intelligent decision-making, and full traceability of quality.

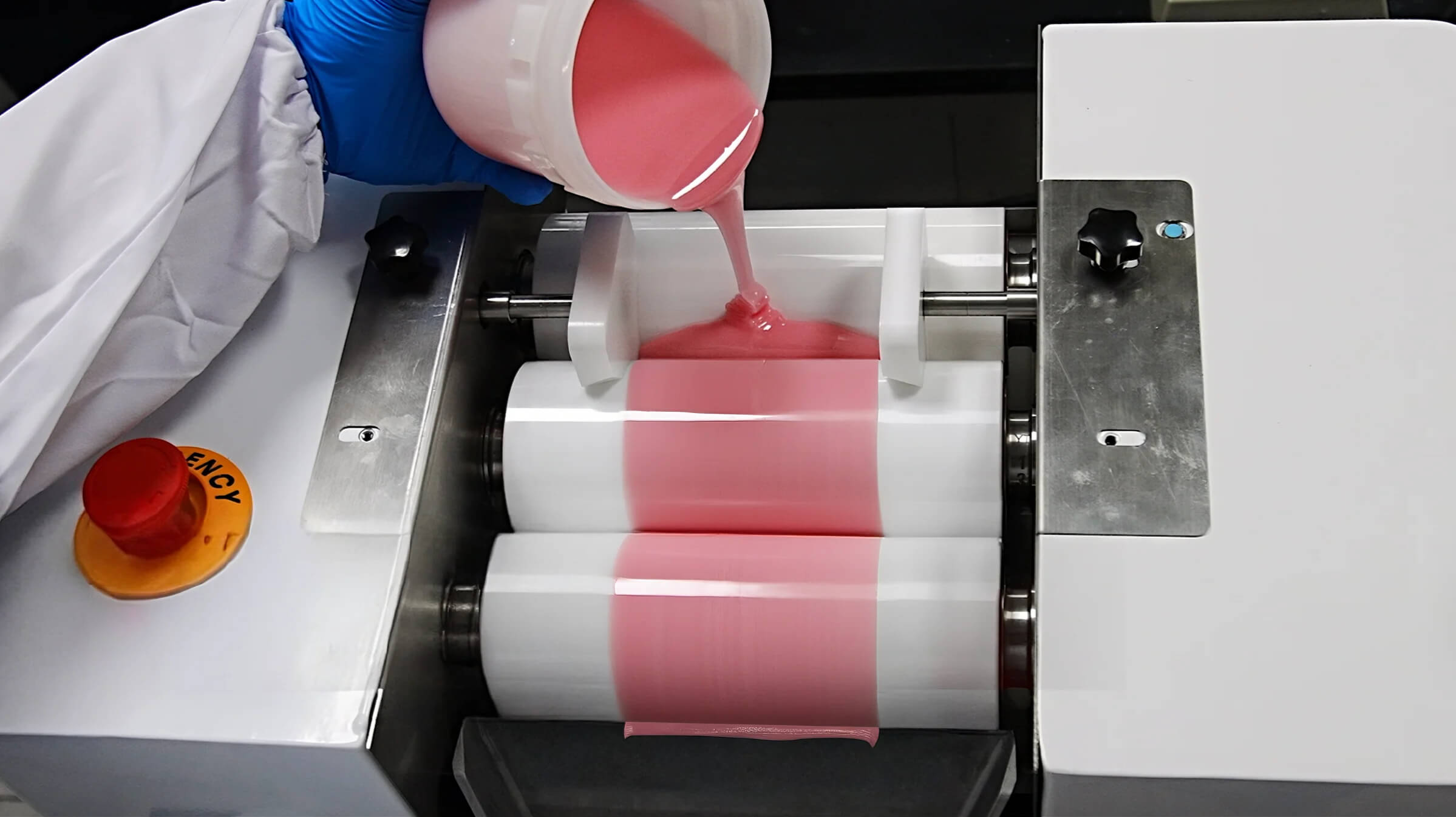

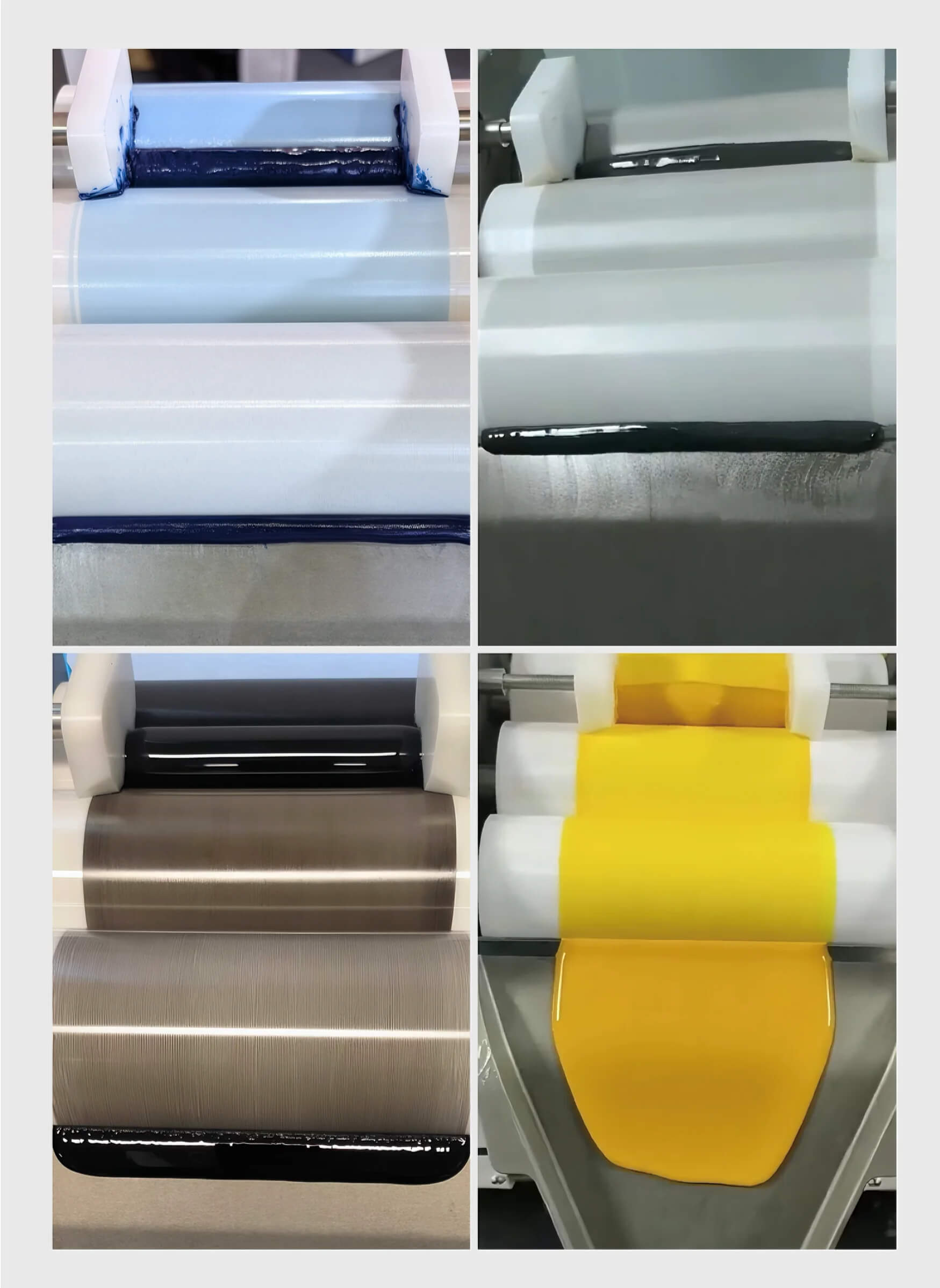

ZYE Three Roll Mill Slurry Grinding Case

In today’s fast-changing and competitive market, ZYE three roll mills enable enterprises to secure a decisive edge and unlock greater space for growth.