Marketing Event | ZYE At CIBF 2025, Empowering A New Leap in The Battery Industry

2025-05-21 17:00

From May 15th to 17th, the 17th China International Battery Fair (CIBF 2025) successfully concluded at the Shenzhen World Exhibition & Convention Center. At this grand event for the battery industry, ZYE Technology, a leading Chinese manufacturer of high-end precision equipment in ultra-niche fields, made a remarkable appearance with its independently developed precision three-roll mill and planetary centrifugal mixer. Not only did ZYE showcase its technical prowess in precision material processing, but it also explored collaboration opportunities and co-created a vision for the industry through exchanges and discussions.

This year's exhibition was massive in scale, featuring 15 halls and nearly 300,000 square meters of exhibition space, bringing together over 3,200 domestic and international exhibitors and more than 400,000 professional visitors. Centered around the theme of "Linking the Globe · Empowering Green · Driving the Future," the event highlighted global innovations in power batteries, energy storage batteries, 3C batteries, charging/swapping equipment and infrastructure, battery materials, manufacturing equipment, and power/energy storage system solutions. It successfully attracted elite enterprises, research institutions, and industry leaders from around the world to explore new paths for innovative development.

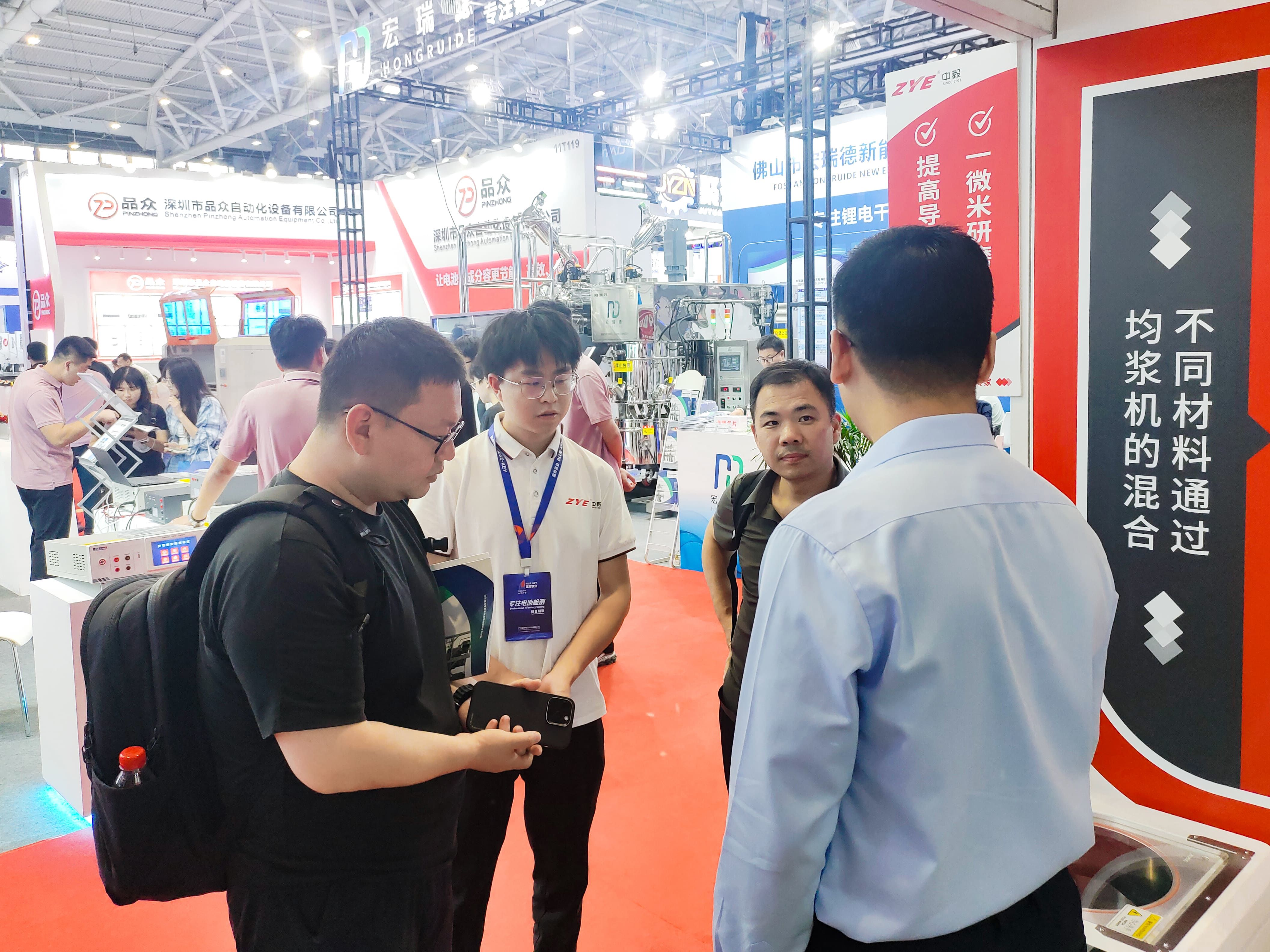

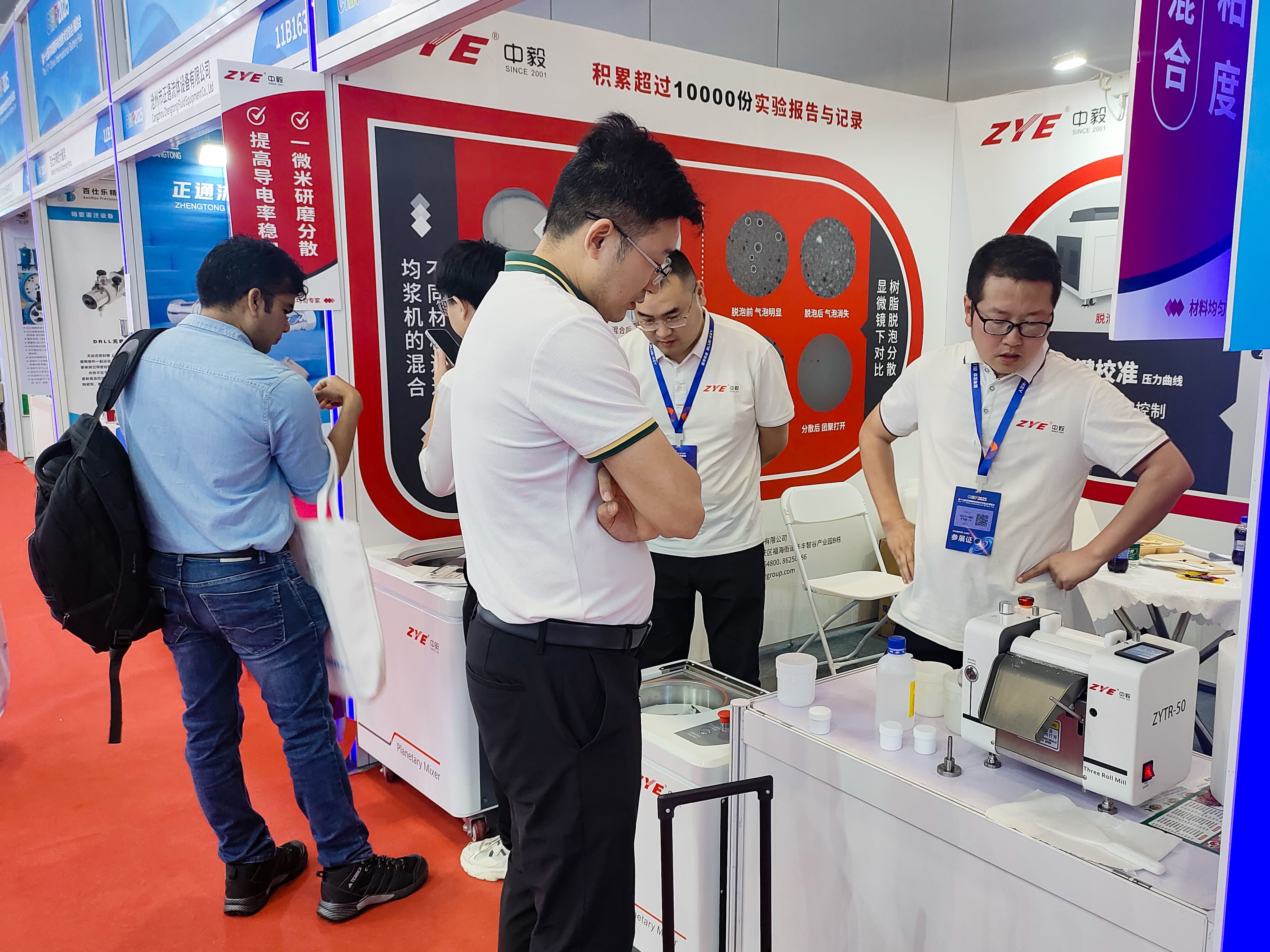

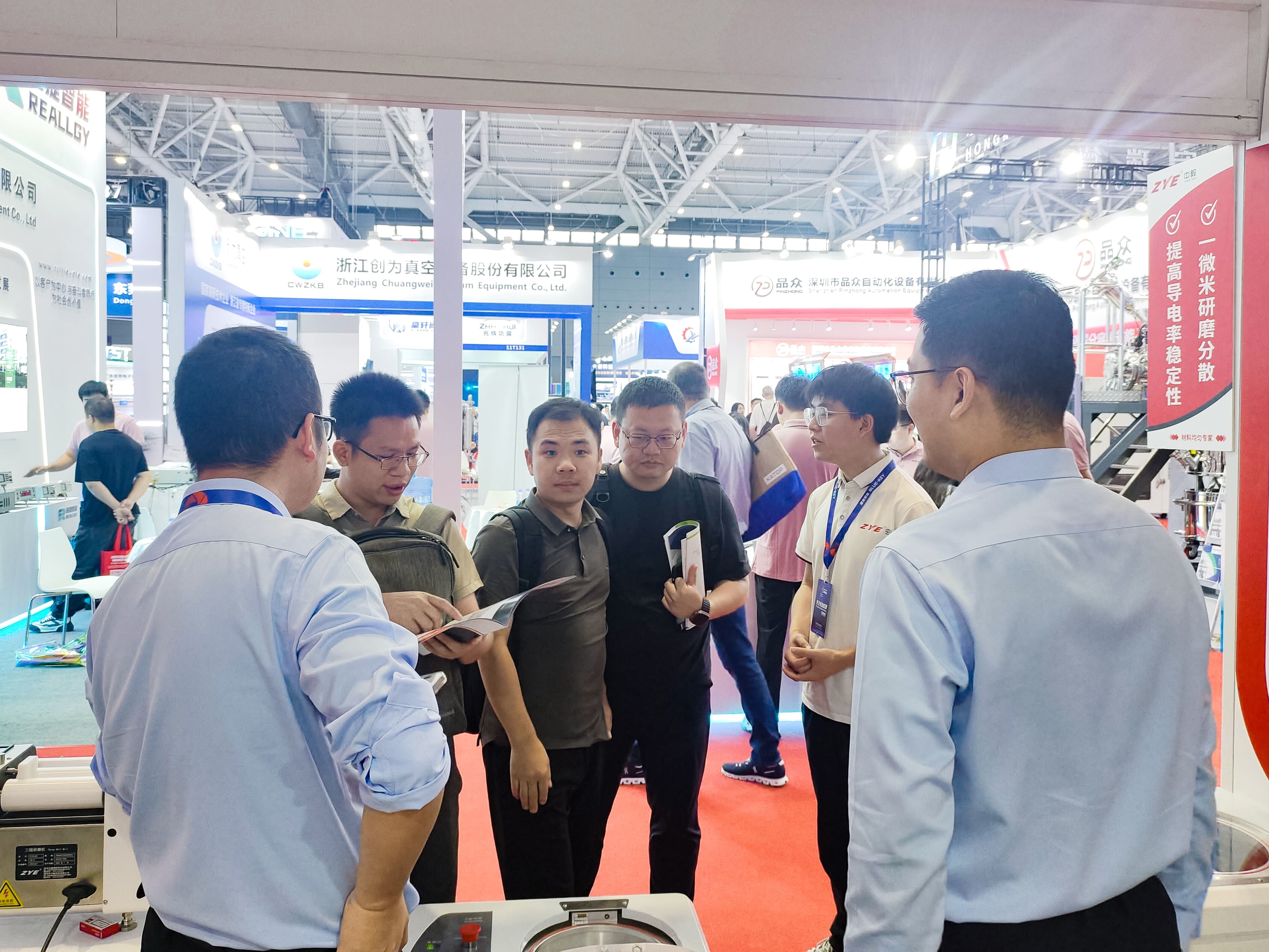

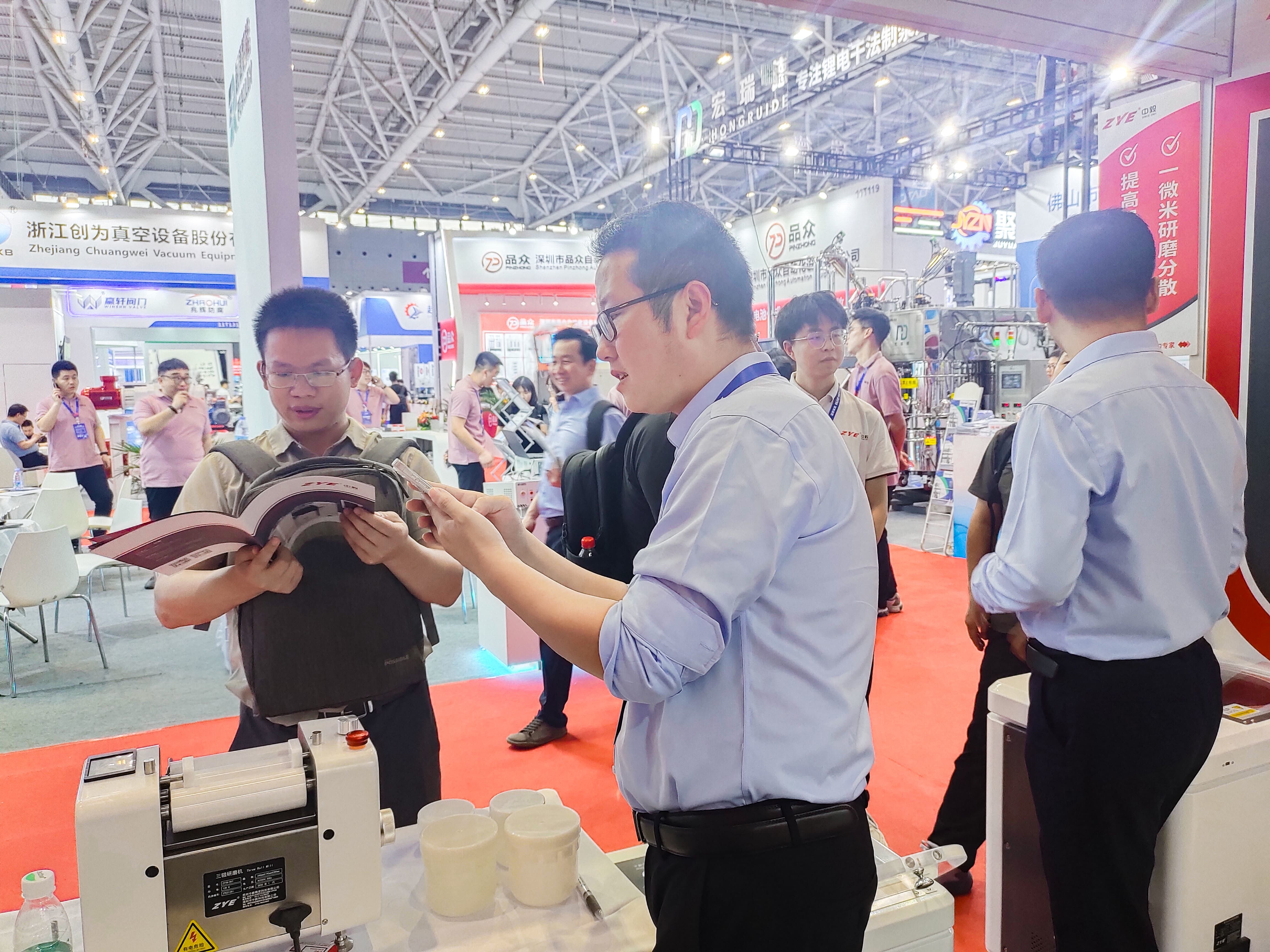

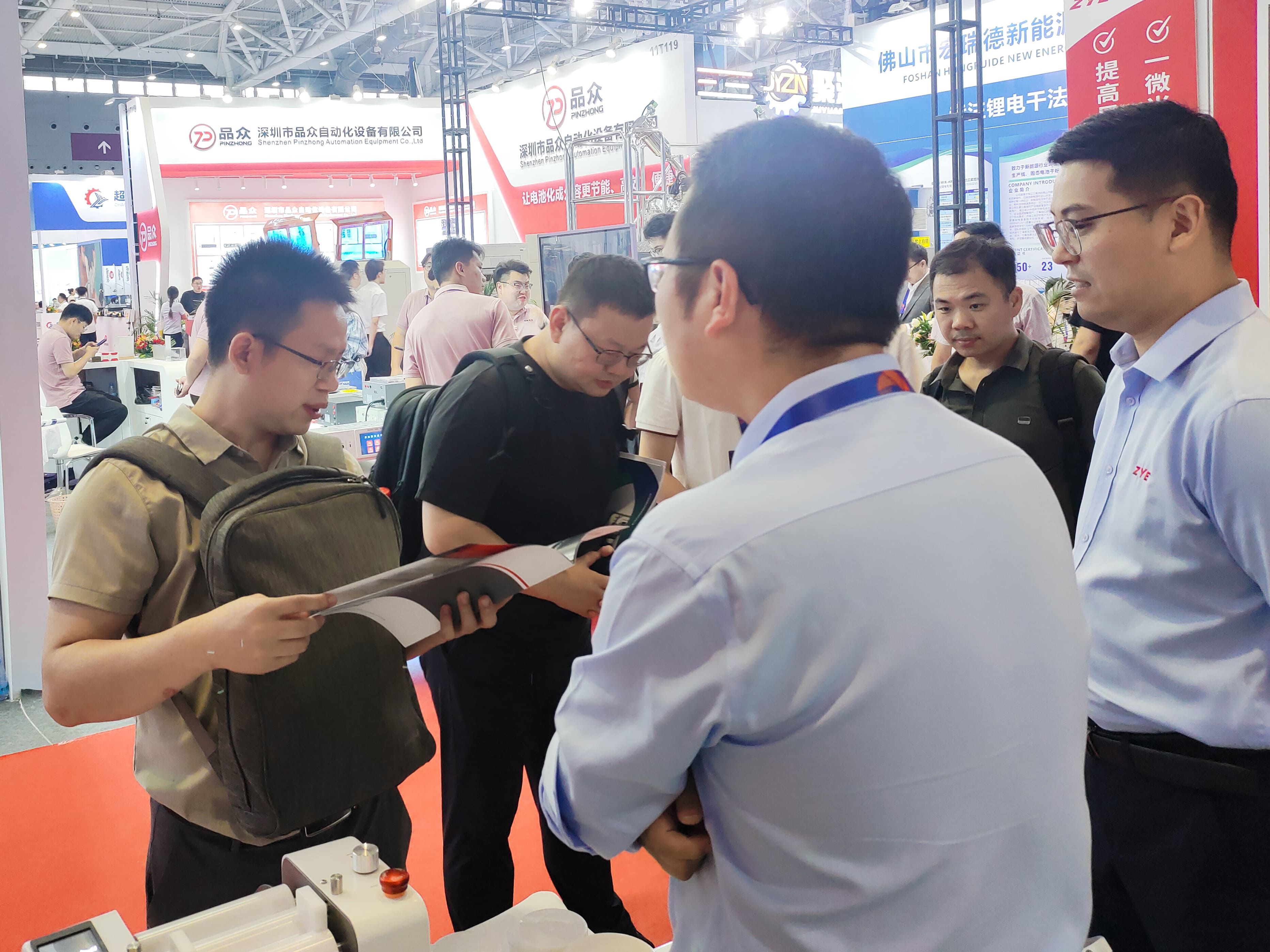

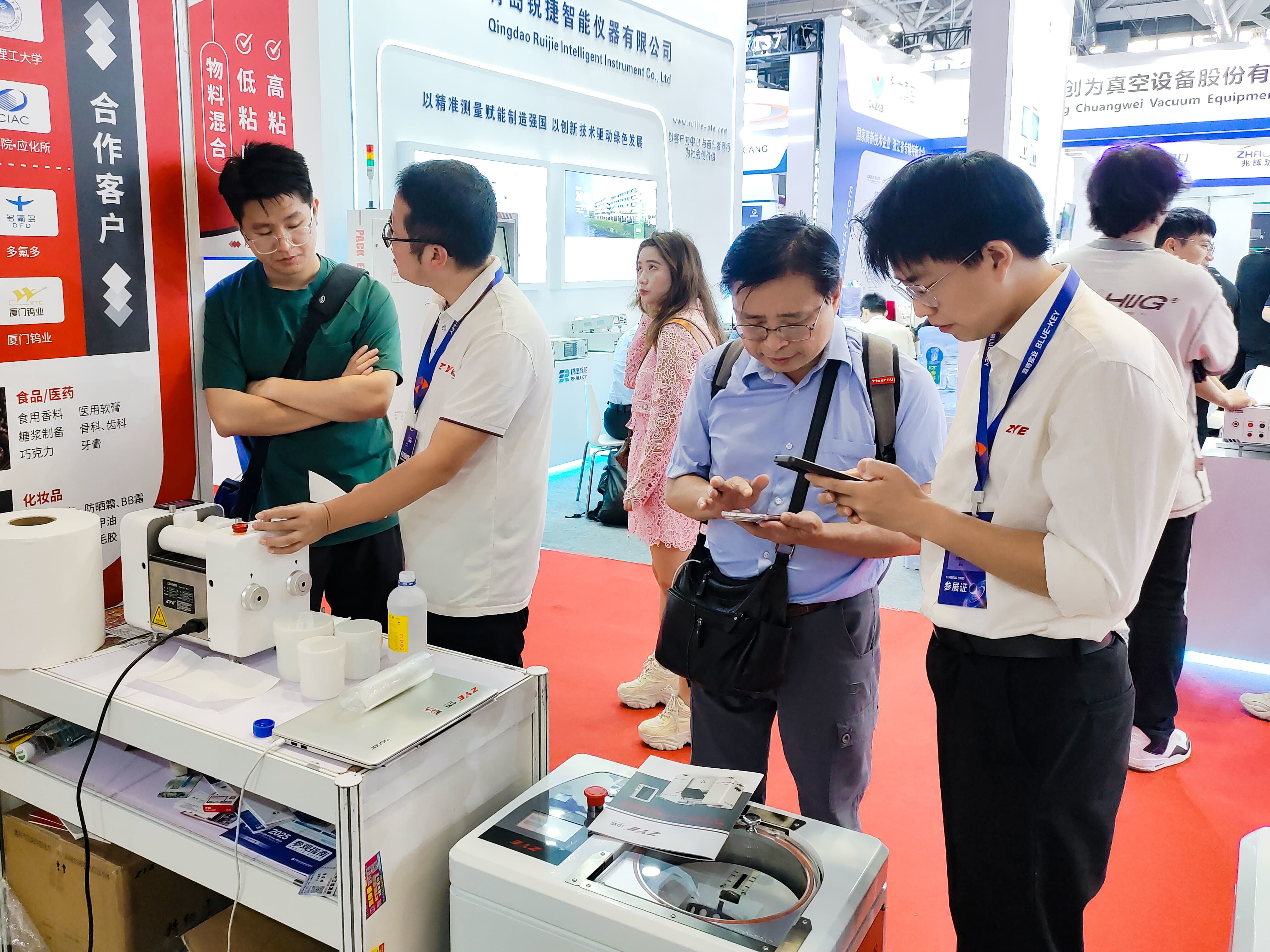

Throughout the three-day exhibition, ZYE's booth remained a hotspot, drawing the attention of professional visitors from across the globe. The independently developed precision three-roll mill and planetary centrifugal mixer, paired with expert on-site explanations, instantly captivated attendees. Numerous industry peers and potential customers approached for consultations, expressing high recognition for ZYE's innovative products, technological advantages, and application performance.

Highlights

At the exhibition, ZYE's self-developed planetary mixer became a focal point for lithium battery laboratory technology. Compared to imported equipment under the same speed and processing time, ZYE's CoV (Coefficient of Variation) was 21.2% lower than that of Japanese equipment, ensuring superior consistency. Additionally, it improved conductivity by 12.4%, directly optimizing electrode charge transfer efficiency and supporting the development of high-energy-density batteries. Many visitors showed great interest in this outstanding performance.

ZYE has achieved a major breakthrough in lithium battery material dispersion technology. The planetary mixer demonstrates exceptional performance in cathode and anode material homogenization, thanks to its innovative speed ratio parameters and rotor cup angle design. Verified by authoritative industry customers, the equipment significantly outperforms Japanese imports in key metrics such as dispersion uniformity and material stability. This technological edge stems from ZYE's in-depth research on lithium battery material properties, integrating interdisciplinary innovation in material science, mechanical design, and process engineering to establish an industry-leading "Material-Equipment-Process" tri-system solution. This provides the lithium battery industry with high-end domestic equipment options featuring independent intellectual property rights.

On-site, the ZYE team engaged in in-depth discussions with visitors about product applications and solutions, patiently addressing every inquiry. Many visitors expressed immediate collaboration intentions after detailed exchanges, reflecting not only high recognition of ZYE's products but also laying a solid foundation for future business expansion. Meanwhile, the outstanding performance of ZYE's precision equipment earned high praise from industry experts, further elevating the brand's reputation and influence.

Technical Advantages

Material performance is a critical aspect of foundational industrial manufacturing, where mixing and dispersion are central to high-end fine material preparation. The effectiveness of dispersion directly impacts material properties and real-world applications. Different mixing processes and equipment influence the physical and chemical characteristics of materials, such as strength, thermal conductivity, electrical performance, and mechanical properties-factors that determine industrial applications. With its flagship three-roll mill and planetary centrifugal mixer, ZYE provides key solutions for the industry.

01

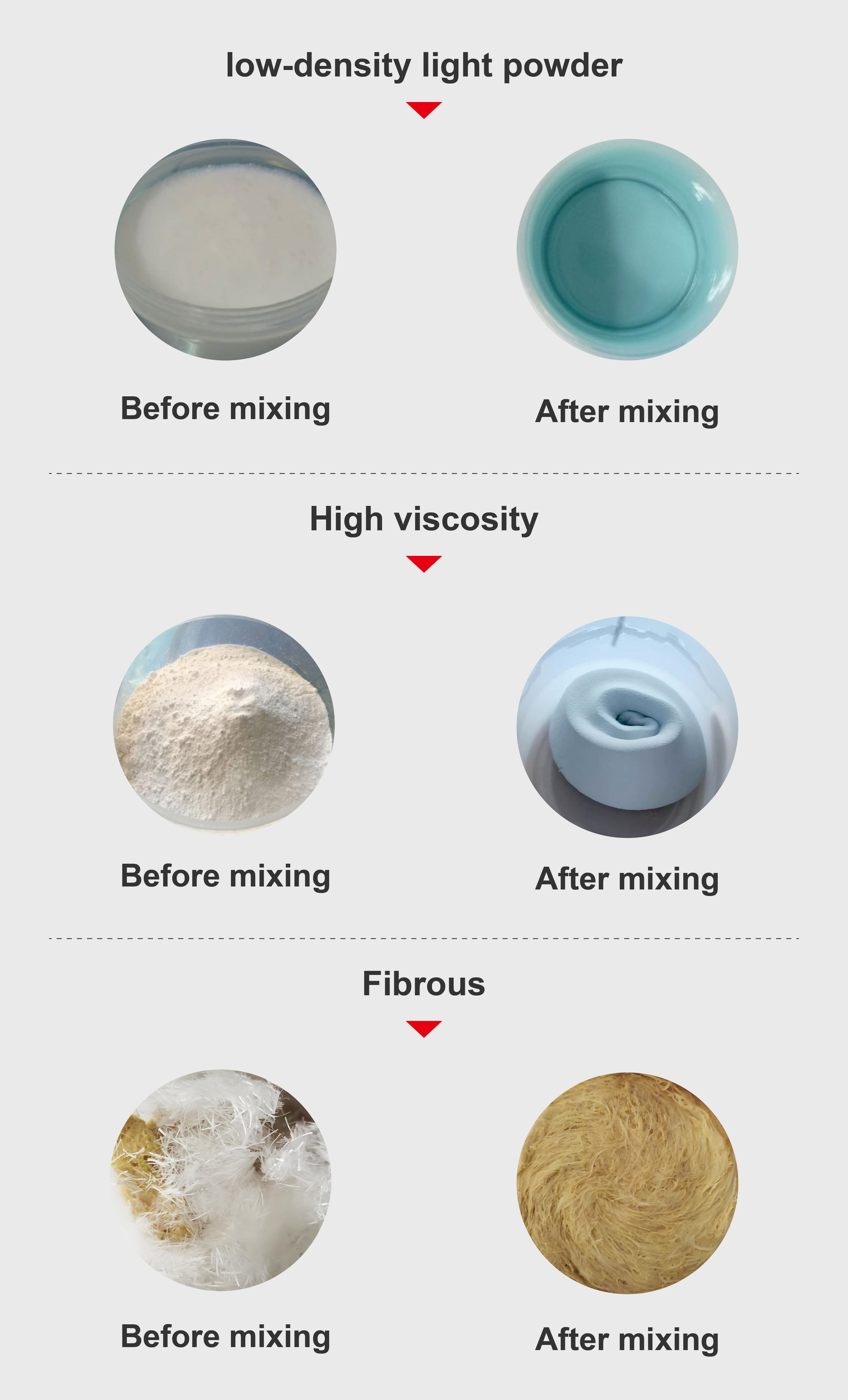

Mixing Materials of Different Viscosities with a Planetary Mixer

In the battery material sector, the planetary mixer is a core device ensuring material stability. By precisely controlling mixing and defoaming processes, it significantly enhances the uniformity and stability of electrode slurries, electrolytes, and other materials.

In lithium-ion battery R&D, it deeply processes electrode slurries, eliminating internal bubbles to prevent coating inconsistencies, thereby improving energy density and cycle life. For solid-state battery manufacturing, it ensures homogeneous mixing of solid electrolyte slurries without bubbles, reducing interfacial resistance and enhancing ion transport efficiency and safety. In zinc-ion, sodium-ion, and other next-gen battery R&D and manufacturing, it guarantees high-quality mixing of electrode materials and electrolytes, minimizing bubble-induced performance degradation.

As battery technology advances toward higher energy density, longer cycle life, and enhanced safety, material quality requirements rise. ZYE's planetary mixer is evolving toward intelligence and efficiency, becoming a vital force in driving battery industry upgrades.

Illustration: Various materials being mixed by a planetary centrifugal mixer

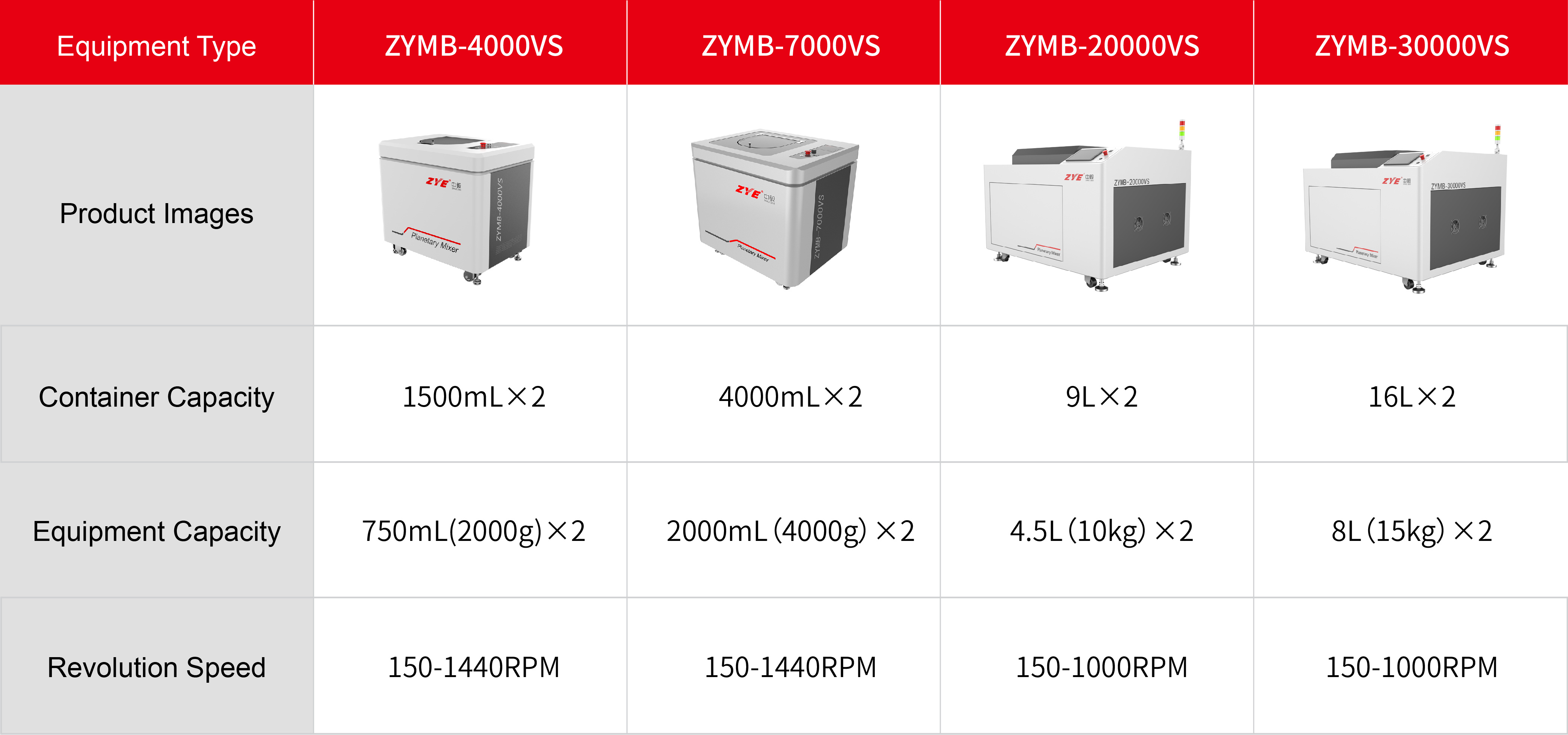

Multiple models available

02

Applications of the Three-Roll Mill in Battery Materials

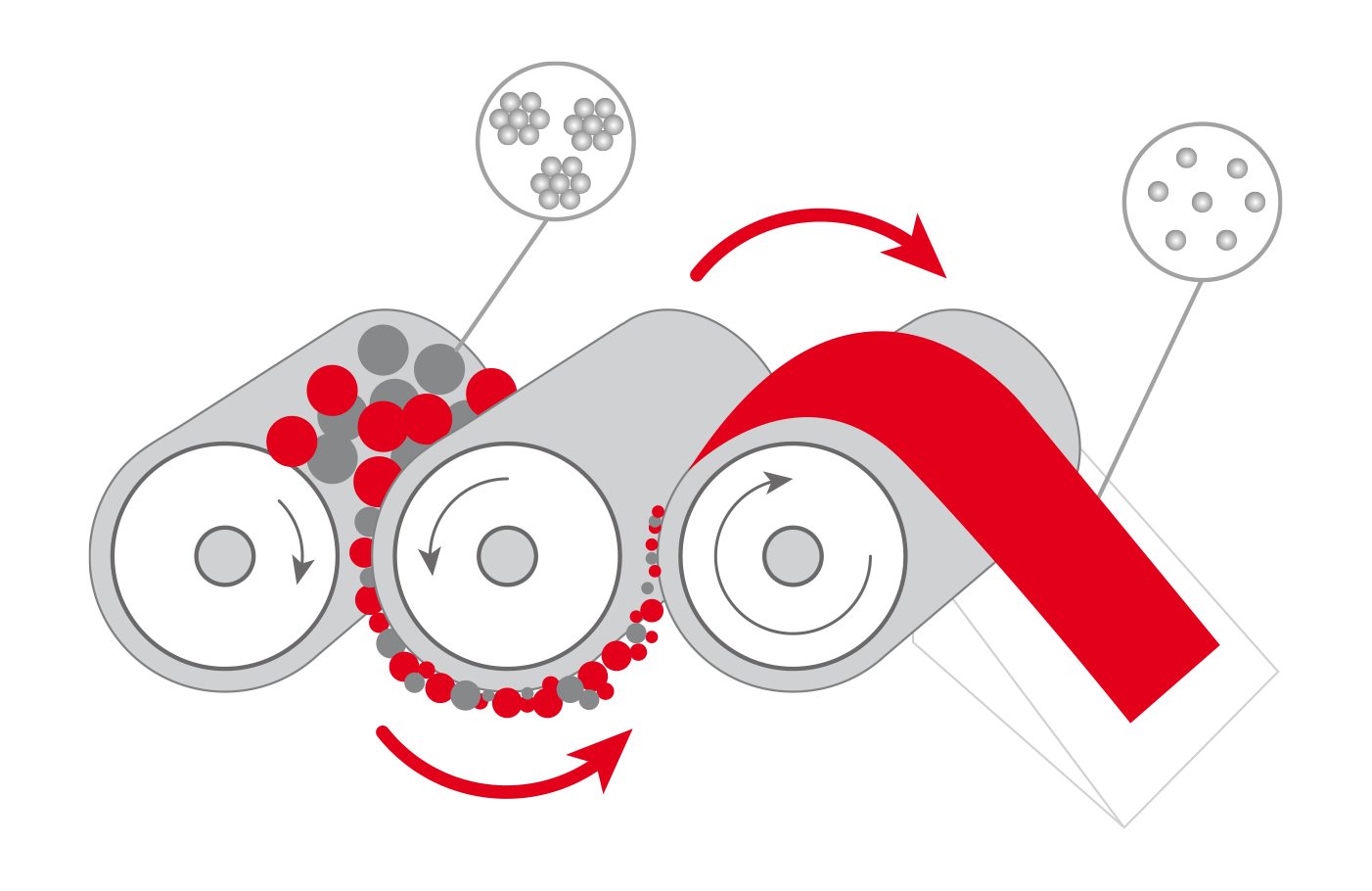

ZYE's precision three-roll mill is the most effective dispersion equipment for medium-to-high-viscosity materials, achieving sub-micron-level fine dispersion while ensuring optimal particle size concentration, widely used in electrode slurry preparation. Its core principle relies on the shear force generated by three horizontally aligned rollers rotating at different speeds, pressing against each other. With ZYE's precise gap control, it achieves deagglomeration without damaging material morphology.

In battery materials, the three-roll mill is deeply applied in electrode slurry preparation and next-gen battery material R&D. Through unique shearing, compressing, and grinding mechanisms, it uniformly disperses active materials, binders, and other components, refining particle size to enhance slurry conductivity and stability, ensuring electrode density and quality. Whether meeting the high-performance demands of lithium-ion batteries or advancing materials for potassium-ion and zinc batteries, the three-roll mill plays a pivotal role.

As battery technology progresses toward higher energy density and longer cycle life-alongside the emergence of new materials-the three-roll mill's high-efficiency dispersion and precision processing capabilities will continue driving material performance optimization, helping the industry break through technical barriers and innovate toward greater efficiency and safety.

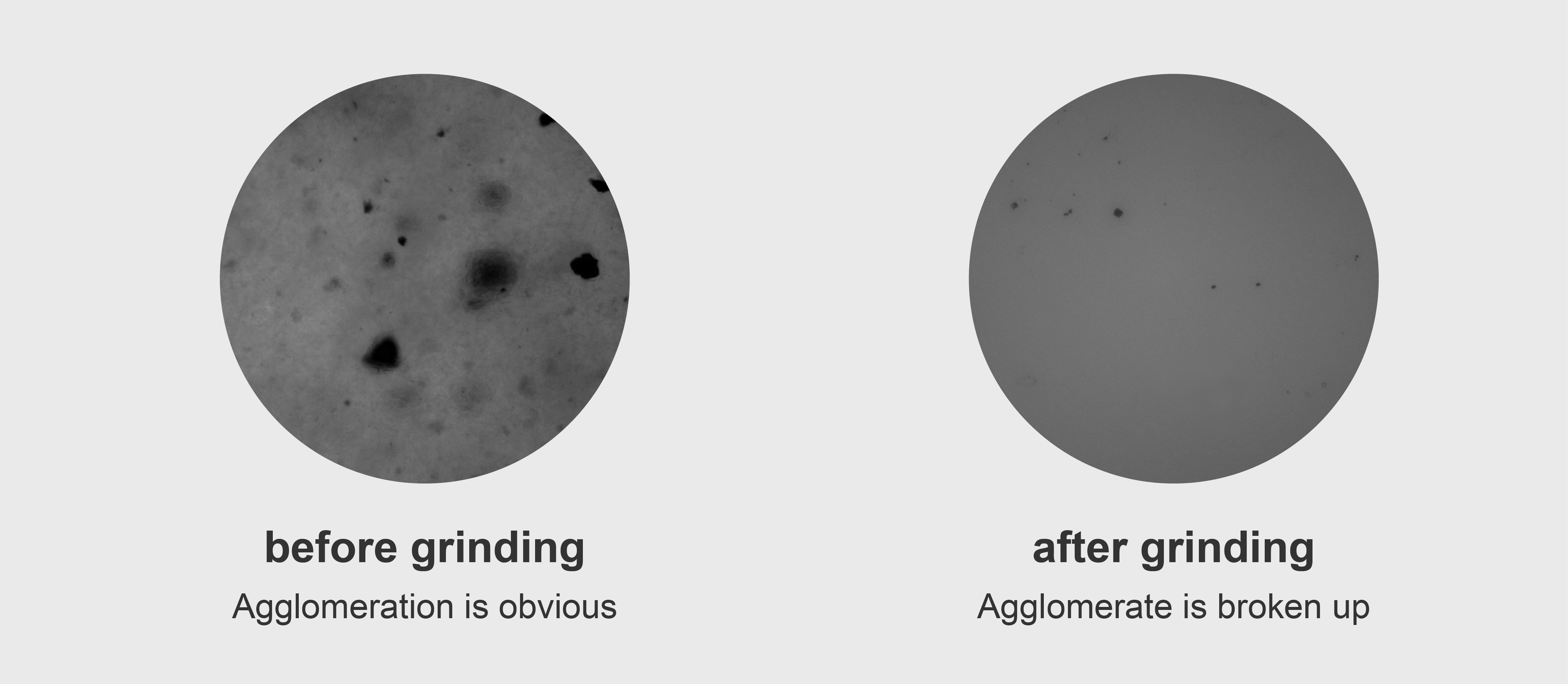

Microscopic comparison images showing resin before and after dispersion

From the comparative microscope images, it is evident that after grinding and dispersion with the precision three-roll mill, the deagglomeration and dispersion effects are significant, with the processed material exhibiting greatly improved dispersity and uniformity.

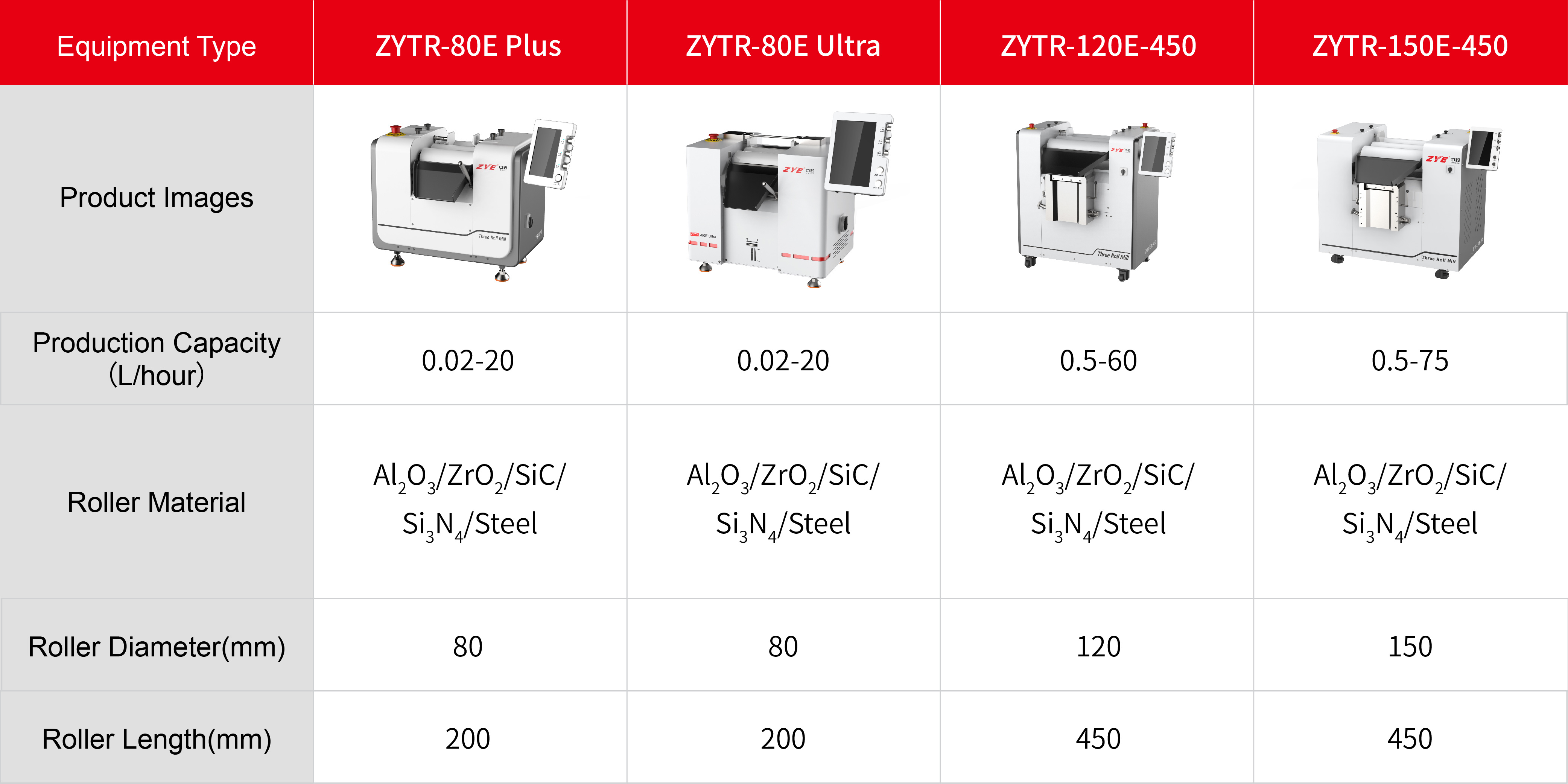

Multiple models available

Summary

CIBF2025 Though CIBF 2025 has concluded, ZYE's journey of innovation never stops. This exhibition not only demonstrated ZYE's strong capabilities in precision material processing but also provided insights into industry trends and valuable opportunities through exchanges and collaborations. Moving forward, ZYE will continue upholding its spirit of innovation, deepening its expertise in high-end precision equipment manufacturing, optimizing product performance, and enhancing service quality. Together with industry partners, ZYE will contribute even more to advancing global battery industry development and realizing a green energy future.

We sincerely thank all friends who have supported and followed ZYE Technology. We look forward to reuniting next year to explore more possibilities in intelligent manufacturing!