ZYE Technology Debuts at Productronica China 2025, Driving a Leap in Electronics Manufacturing Technology

2025-03-31 14:04

From March 26 to 28, the 2025 Productronica China successfully concluded at the Shanghai New International Expo Center. As a leading manufacturer of high-end precision equipment in China’s ultra-niche segments, ZYE Technology made a remarkable appearance with its independently developed precision three roll mills and vacuum defoaming mixers. By showcasing advanced material processing technologies, ZYE played a key role in driving industry upgrades and breakthroughs, becoming a highlight of the exhibition and earning widespread attention and high praise.

This year’s exhibition was held on a massive scale, spanning nearly 100,000 square meters and attracting over 1,000 exhibitors, covering the entire electronics manufacturing supply chain. The event focused on key themes such as new quality productivity, artificial intelligence, new energy vehicle electronics under the dual carbon goals, and advanced packaging, offering deep insights into the latest industry trends.

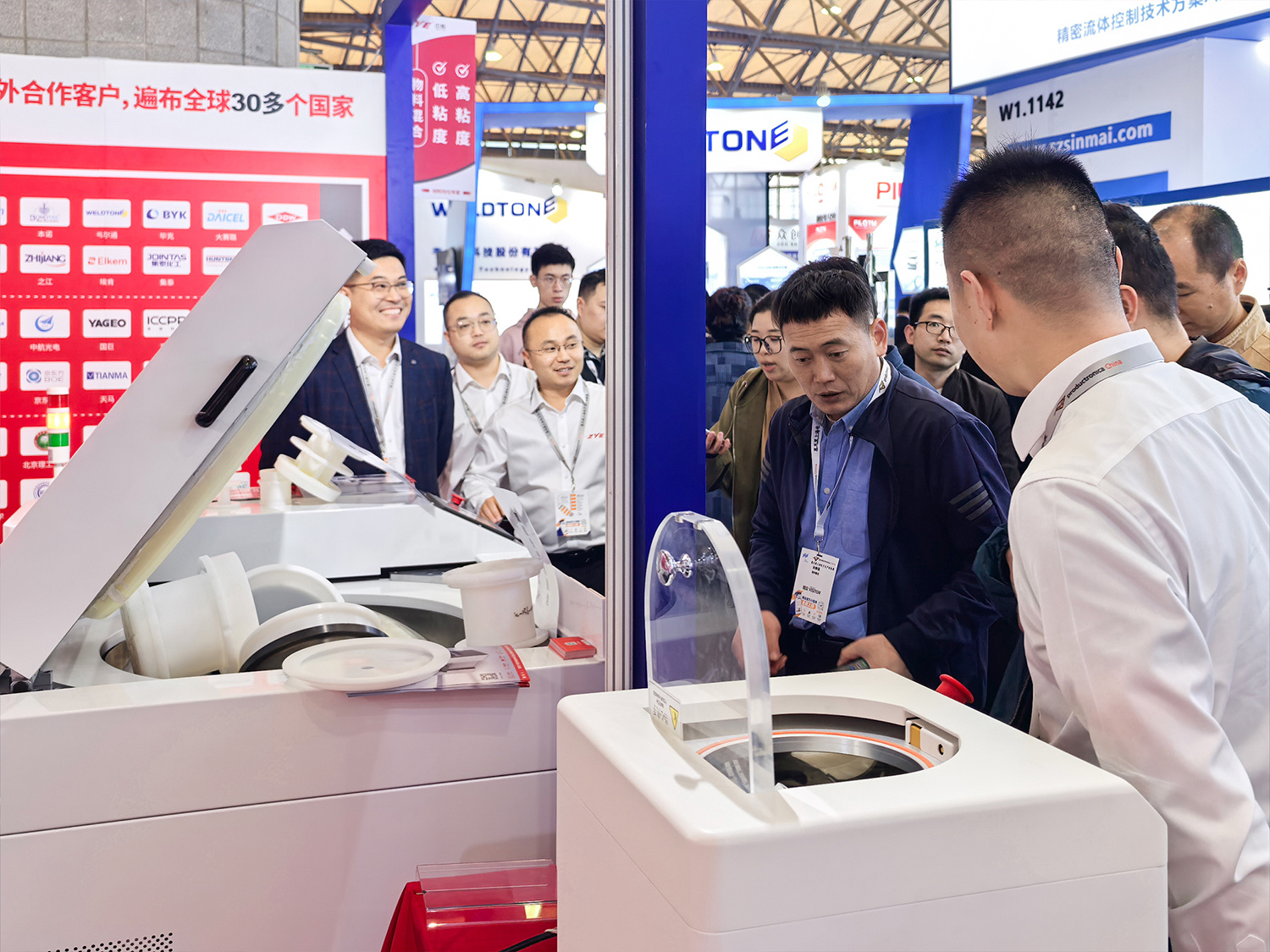

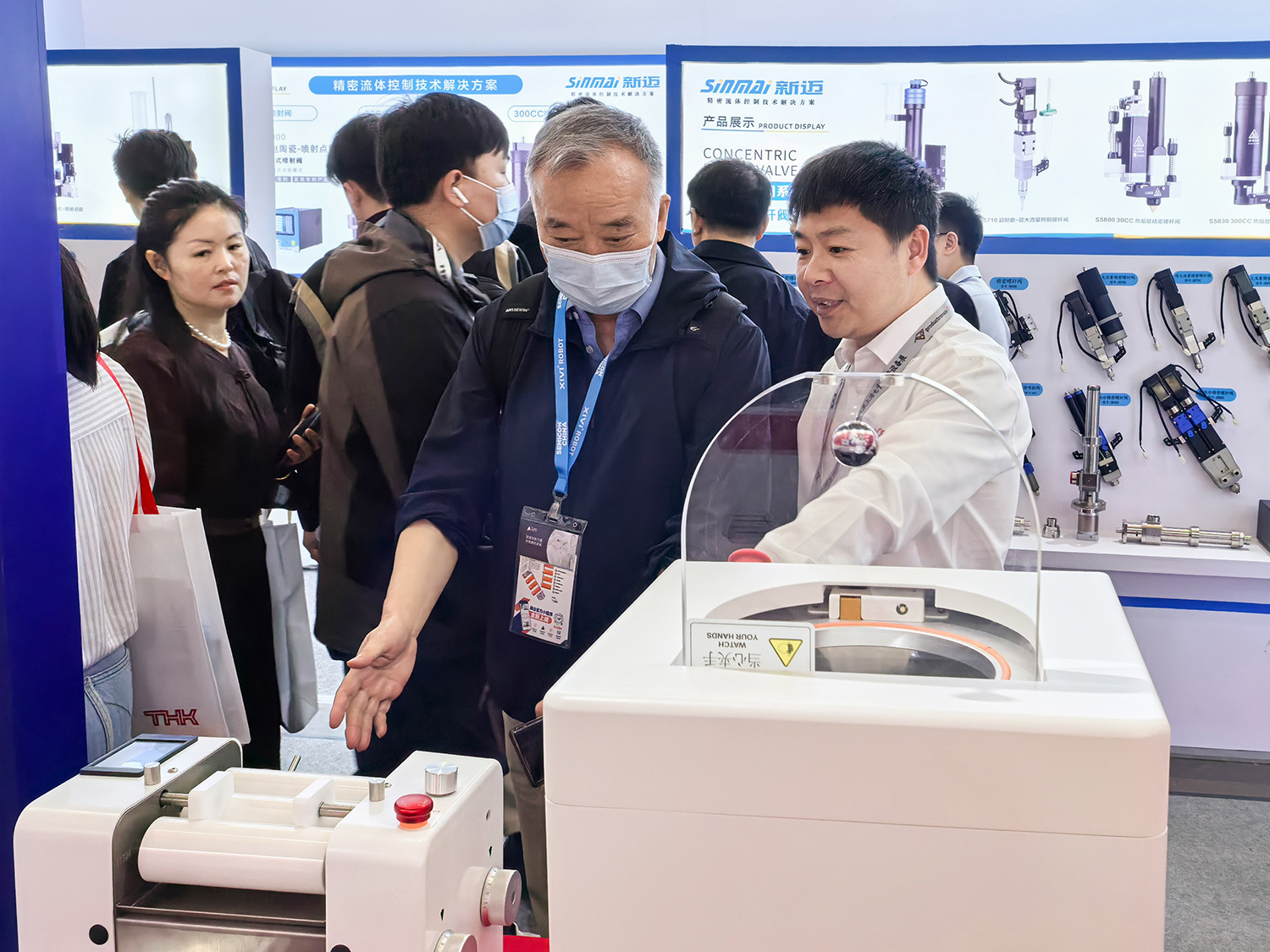

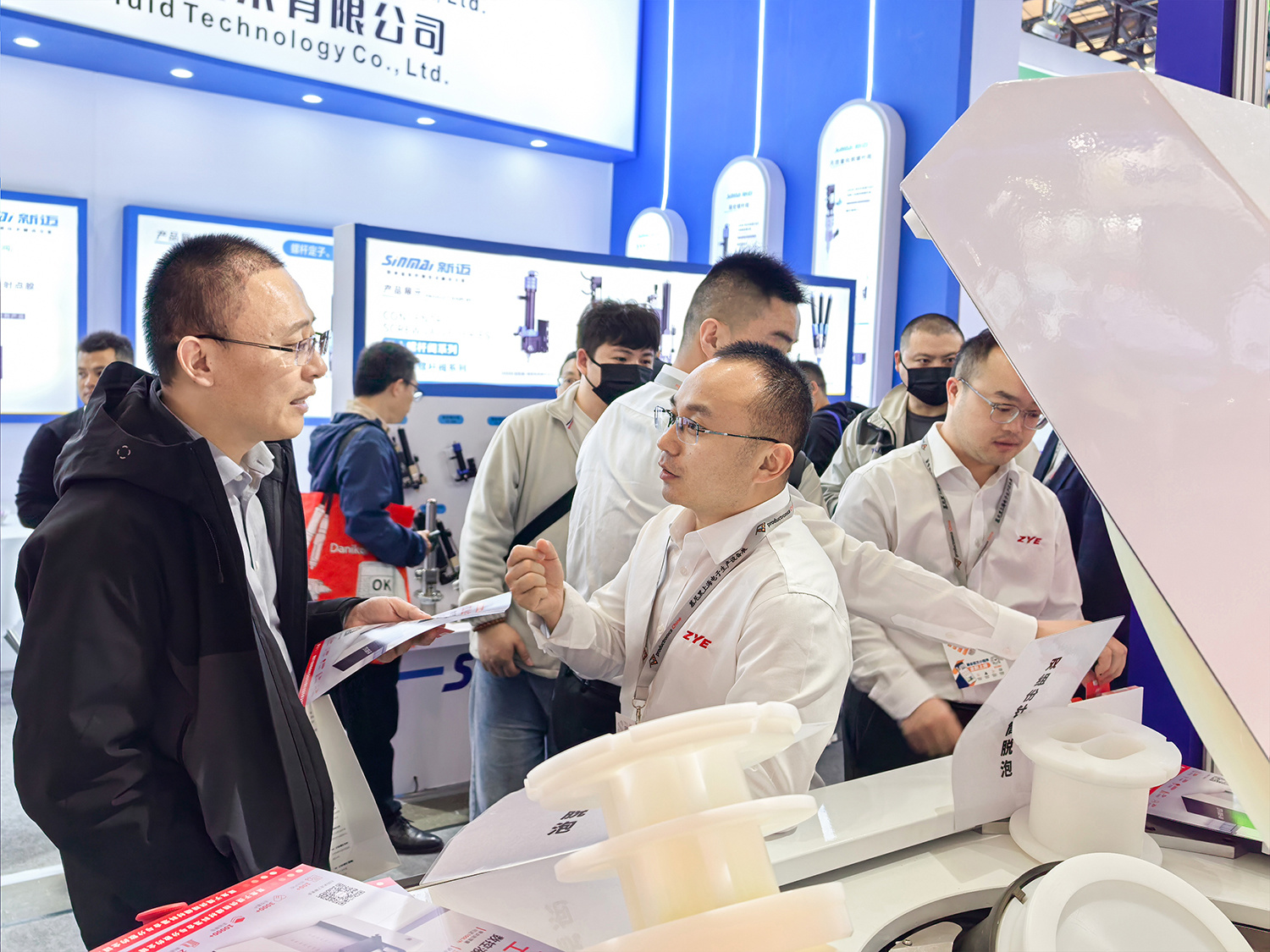

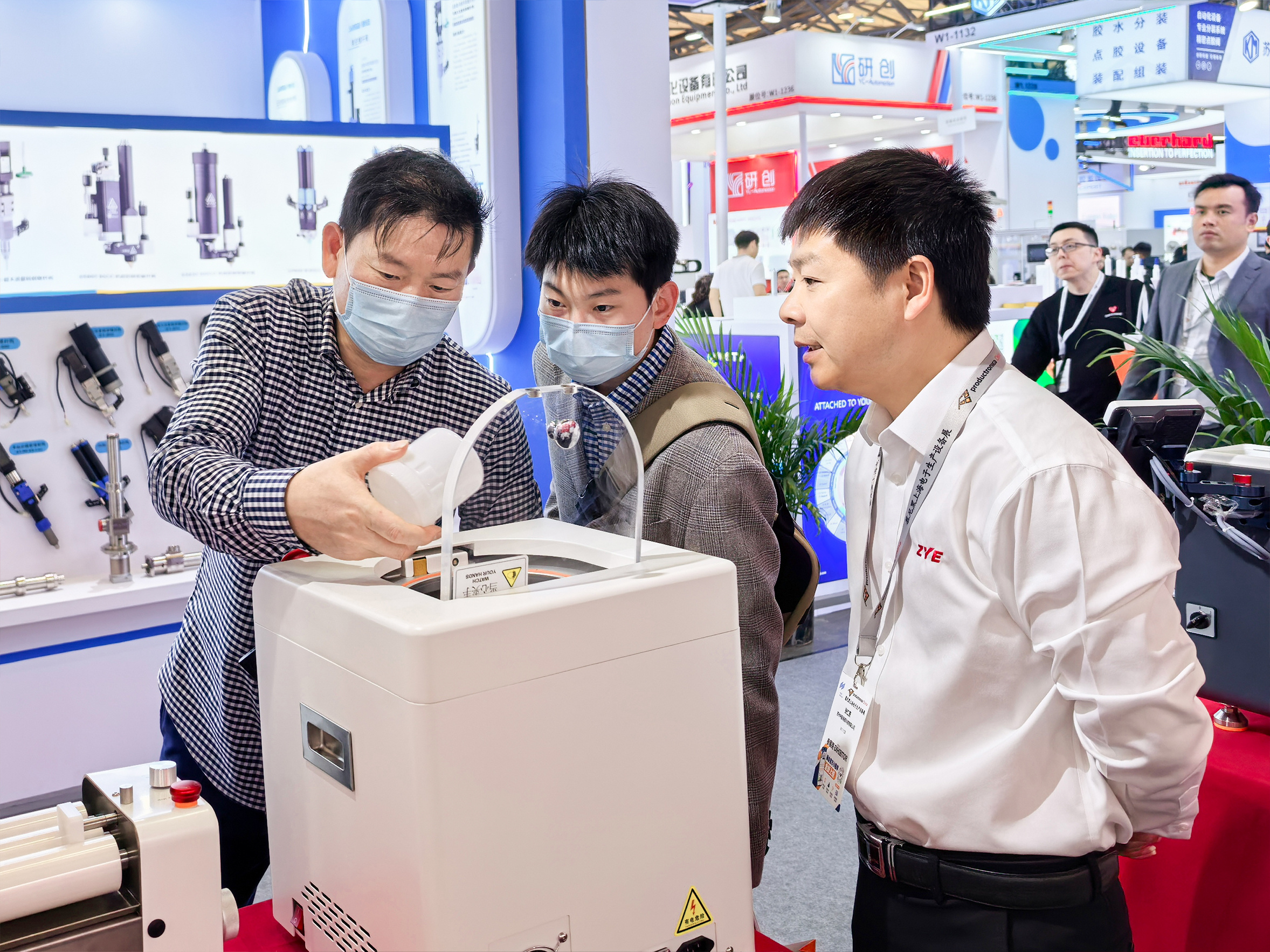

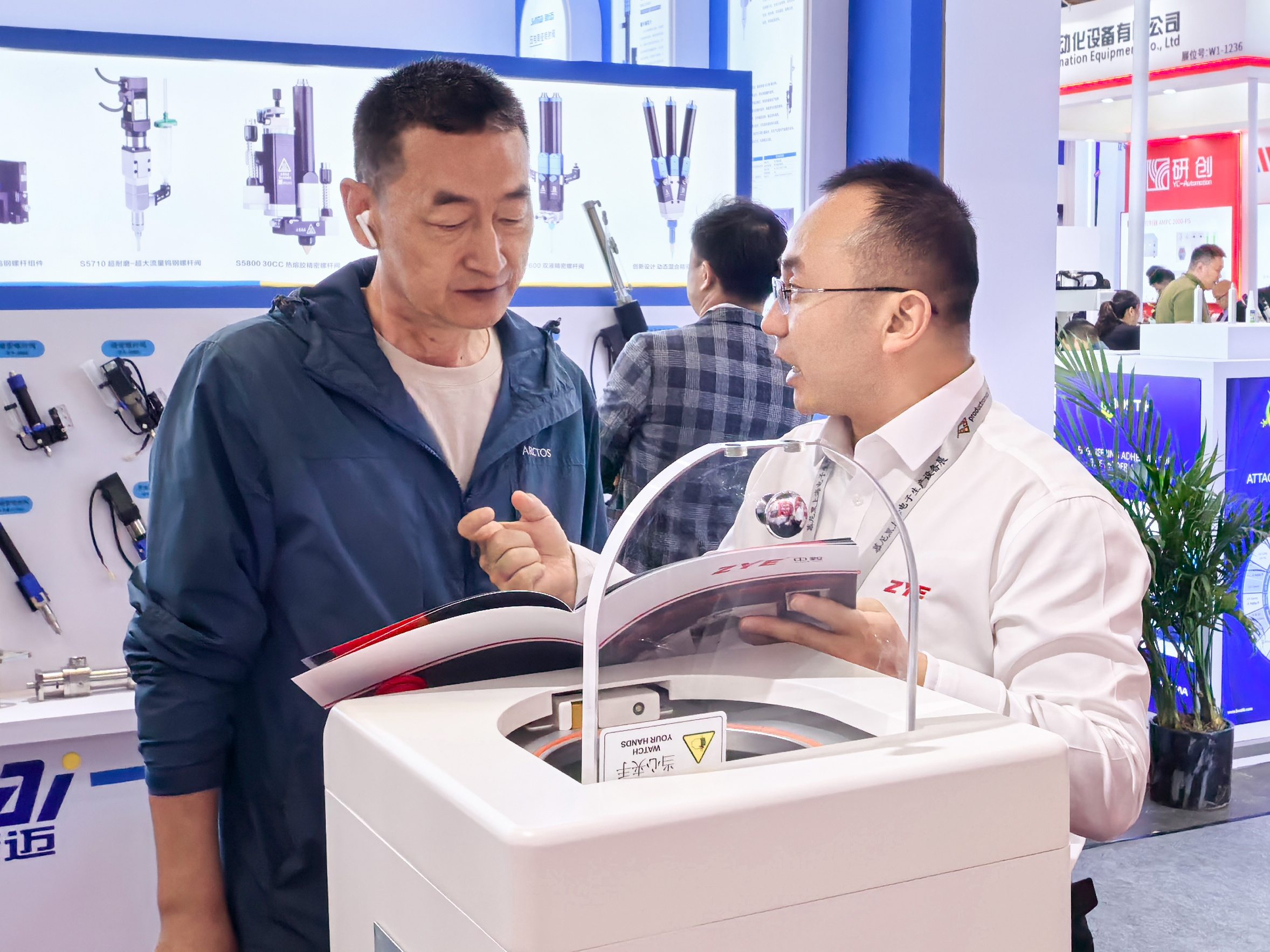

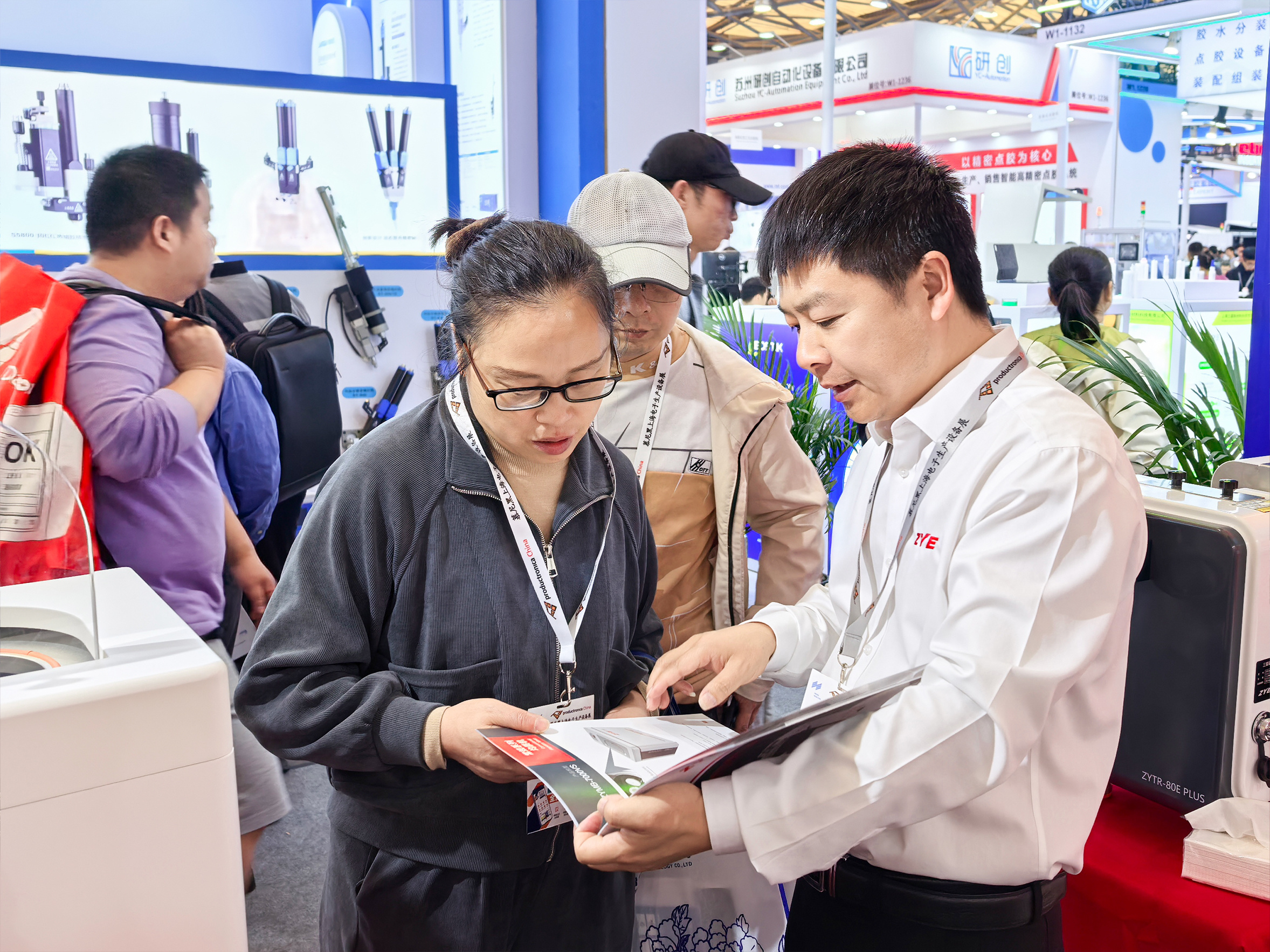

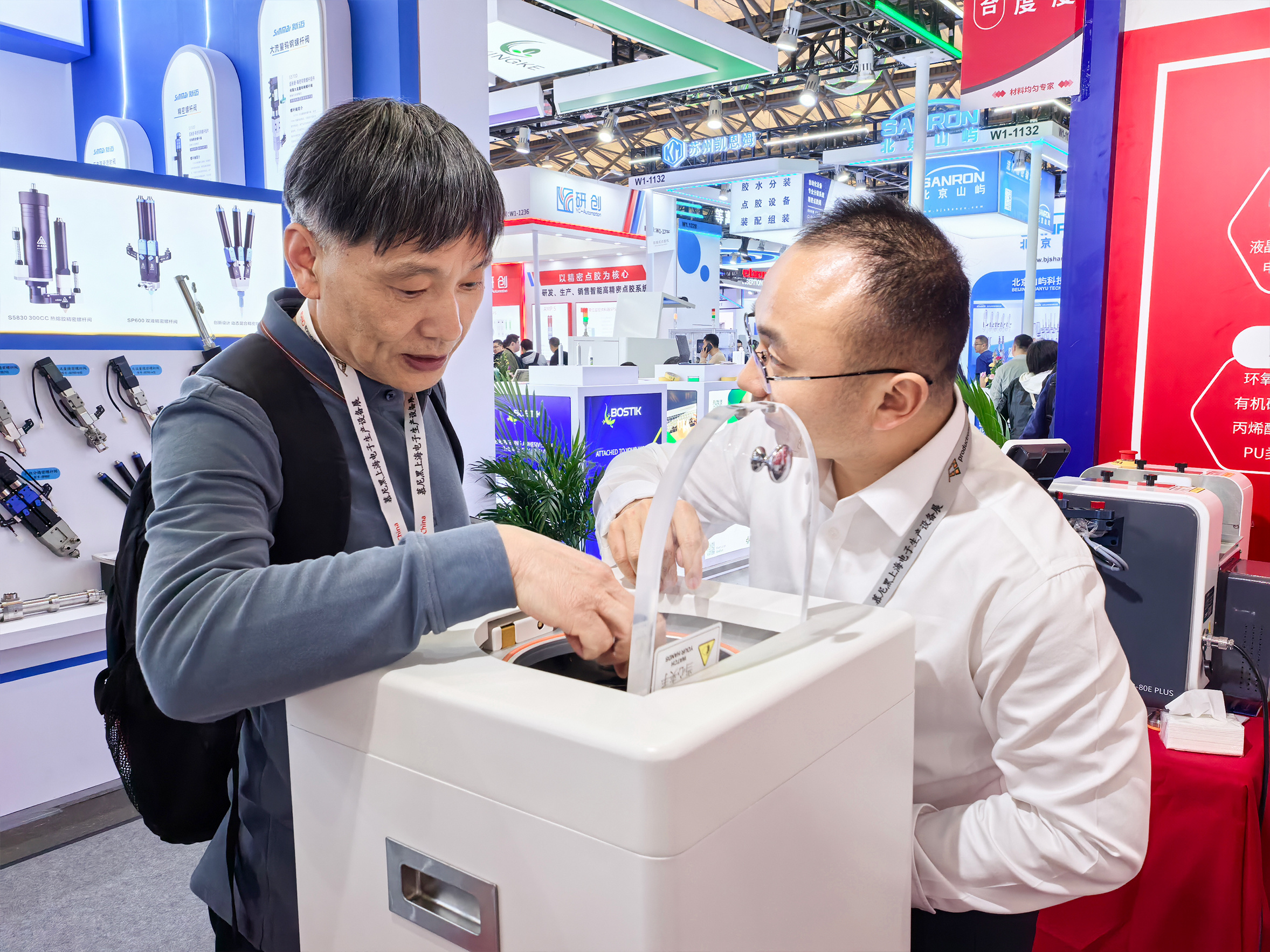

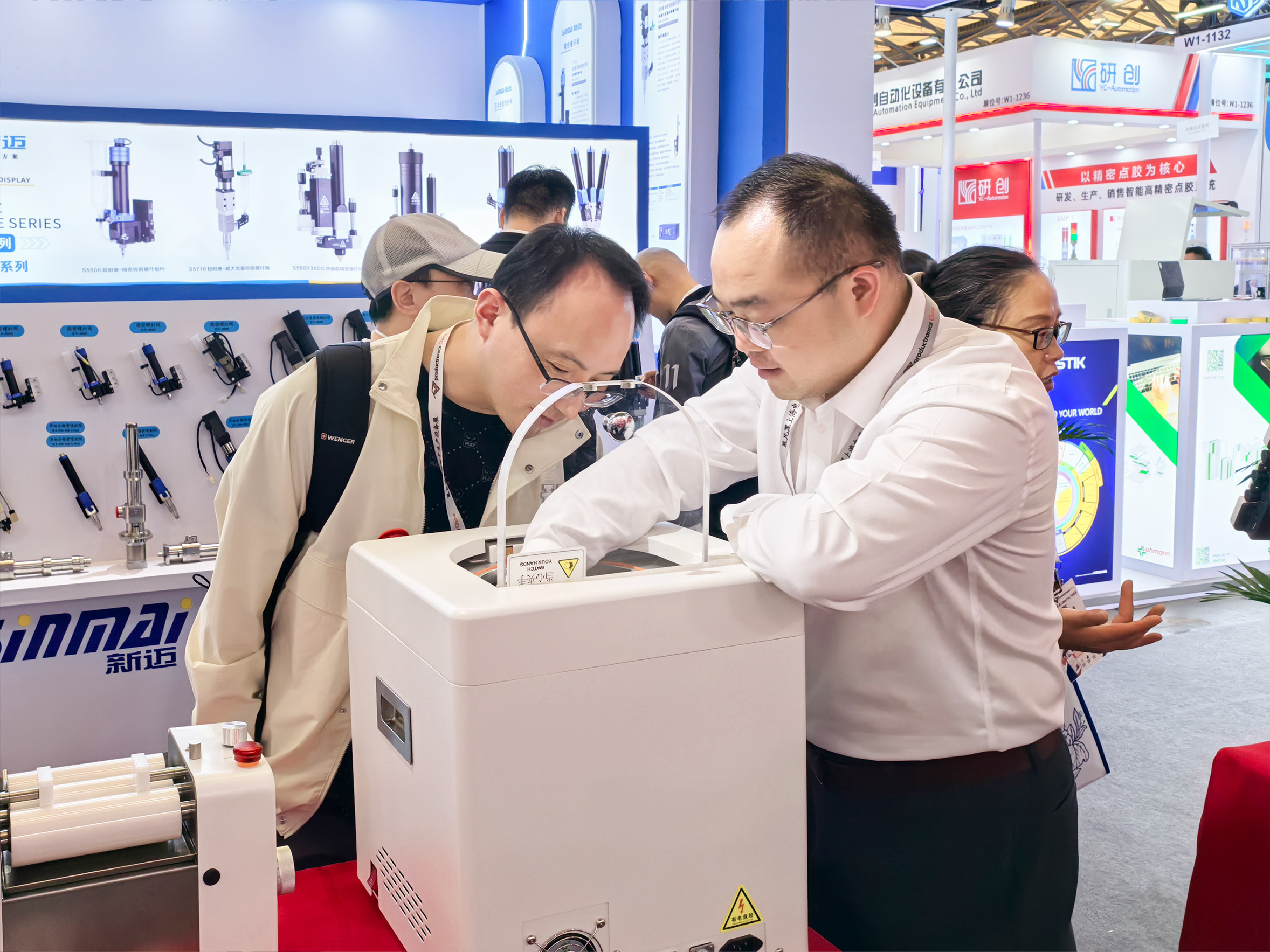

Throughout the three-day exhibition, the ZYE Technology booth remained a hotspot, continuously drawing in a steady stream of professional visitors from around the world. Many attendees showed strong interest in the innovation, technical advantages, and application performance of ZYE’s products. On-site staff engaged patiently with visitors, providing detailed answers and discussing product applications and customized solutions in depth. Numerous visitors expressed clear cooperation intentions on the spot, laying a solid foundation for future business expansion.

Highlights

The upgrade of electronics manufacturing is not merely about "replacing manual labor with machines," but more about restructuring the value of the industrial chain through collaborative innovation between equipment and process. At the exhibition, the ZYE Technology team leveraged their professional expertise to engage visitors with interactive demonstrations and case studies, offering in-depth explanations of technical details. They showcased how ZYE’s equipment pushes the physical limits of precision and stability, and how its intelligent software system enables real-time monitoring of key parameters such as pressure and temperature, ensuring process traceability and control—ultimately enhancing the performance of high-end materials.

During interactions with visitors, the technical strengths of ZYE’s precision equipment became a major focal point. The precision three roll mills, with their high-accuracy gap control and stable grinding performance, meet the stringent requirements for particle size uniformity in advanced sectors such as electronic materials and semiconductor pastes, effectively improving both product quality and production efficiency.

Meanwhile, the non-contact homogenizing mixer offers contamination-free mixing and defoaming, addressing the limitations of traditional mixing methods when handling sensitive materials. This gives it a clear advantage in industries with strict hygiene standards such as cosmetics and pharmaceuticals. Its highly efficient mixing and defoaming capabilities also help shorten production cycles and reduce manufacturing costs.

These technological advantages have not only gained strong recognition from customers but also received high praise from industry experts, further enhancing ZYE Precision’s brand visibility and industry influence.

Technical Advantages

Material performance is a critical process in product manufacturing across foundational industries, and mixing and dispersion play a central role in the preparation of high-end fine materials. The effectiveness of mixing and dispersion directly impacts the performance and practical applications of the materials.

Different mixing technologies and equipment influence the physical and chemical properties of materials—such as strength, thermal conductivity, electrical characteristics, and mechanical behavior—which in turn determine their specific industrial applications.

Leveraging its two flagship technologies—three roll mills and non-contact homogenizing mixers—ZYE Technology provides key solutions to support the industry in achieving higher material performance and production efficiency.

01

Applications Of Three Roll Mills In Electronics Manufacturing

ZYE’s three roll mill is a precision-grade dispersing equipment, specifically designed for high- and medium-viscosity materials. It enables submicron-level fine dispersion while achieving an optimal particle size distribution, making it one of the most effective solutions for precision mixing. Widely used in material preparation and processing within the electronics manufacturing sector, its core mechanism involves three horizontally aligned rollers. These rollers rotate at different speeds and directions, generating strong shear forces that break down and disperse agglomerated particles.

Thanks to ZYE’s highly precise gap control system, the three roll mill is able to deagglomerate materials without damaging their surface morphology, ensuring both high performance and material integrity.

In the electronics industry, the three roll mill is widely applied in the preparation of conductive pastes and electronic inks, the processing of electronic packaging materials, grinding of electronic ceramic slurries, homogenization of optoelectronic display materials, and in the development of flexible and printed electronics. It plays a crucial role in enhancing key material properties such as electrical conductivity, thermal conductivity, mechanical strength, and material densification.

As electronic materials continue to evolve toward nanostructuring and compositing, the ultra-fine processing capability of ZYE’s three roll mill will further drive technological advancements across the industry.

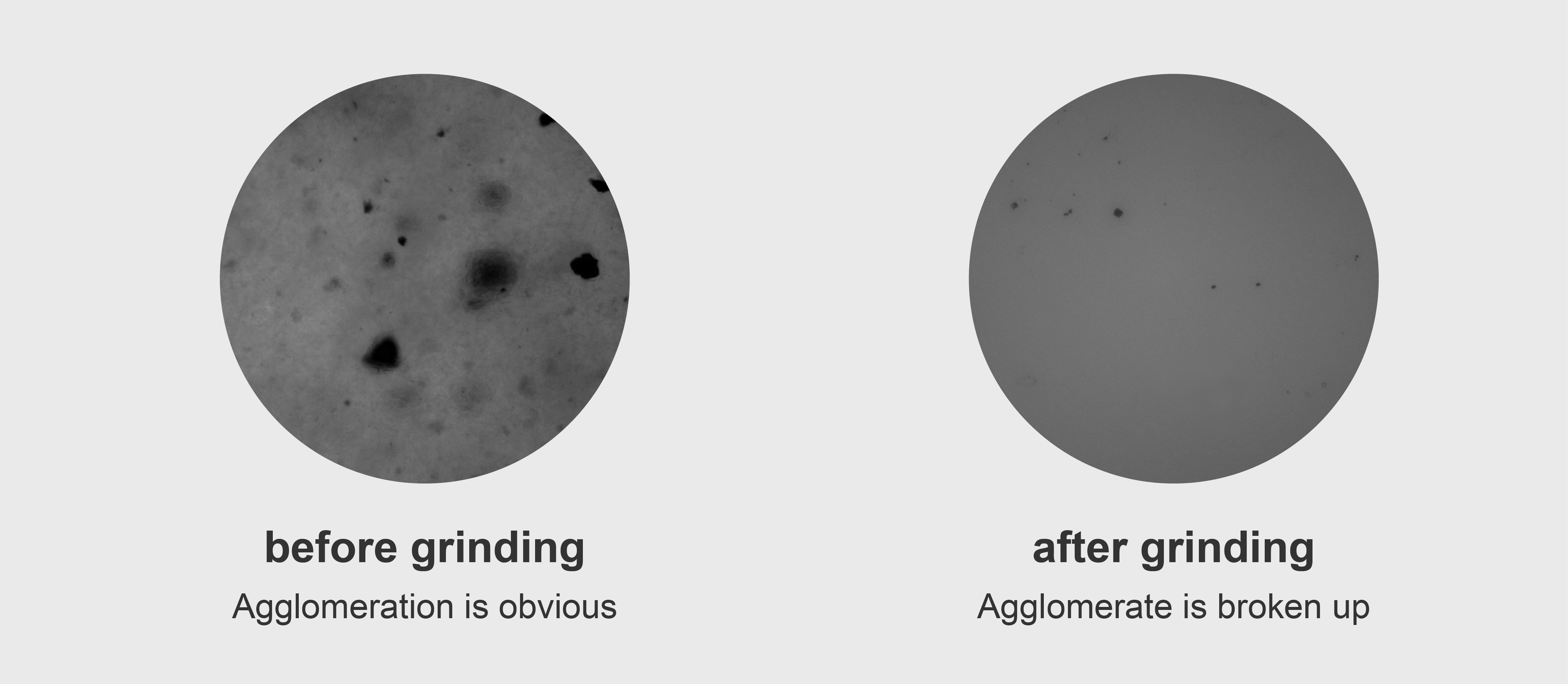

Microscopic Comparison Of Resin Before And After Dispersion

From the microscopic comparison images, it is evident that after grinding and dispersion with a precision three roll mill, the deagglomeration and dispersion effects are significantly improved. The processed material exhibits much higher dispersibility and uniformity, ensuring enhanced performance for high-end applications.

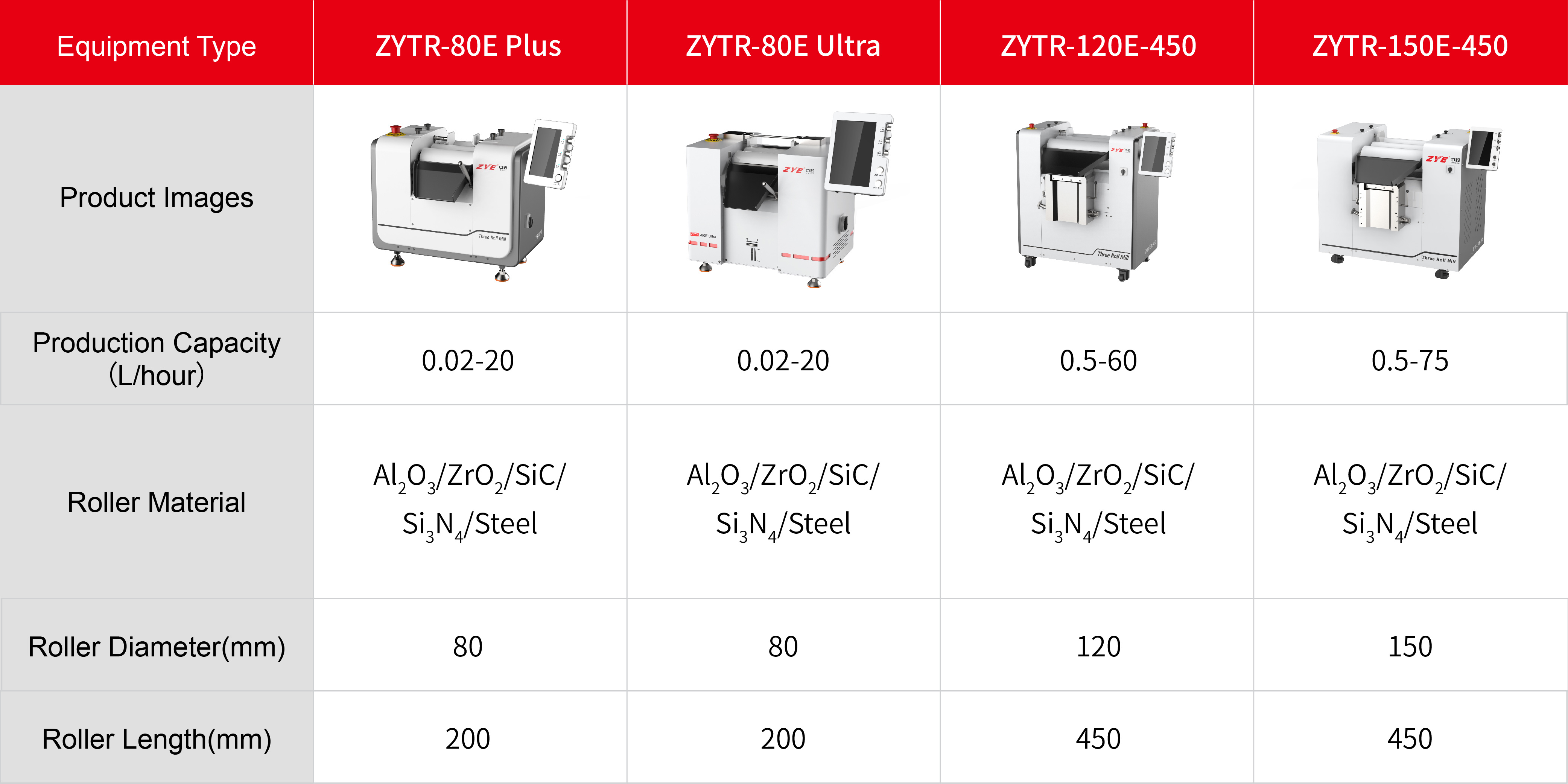

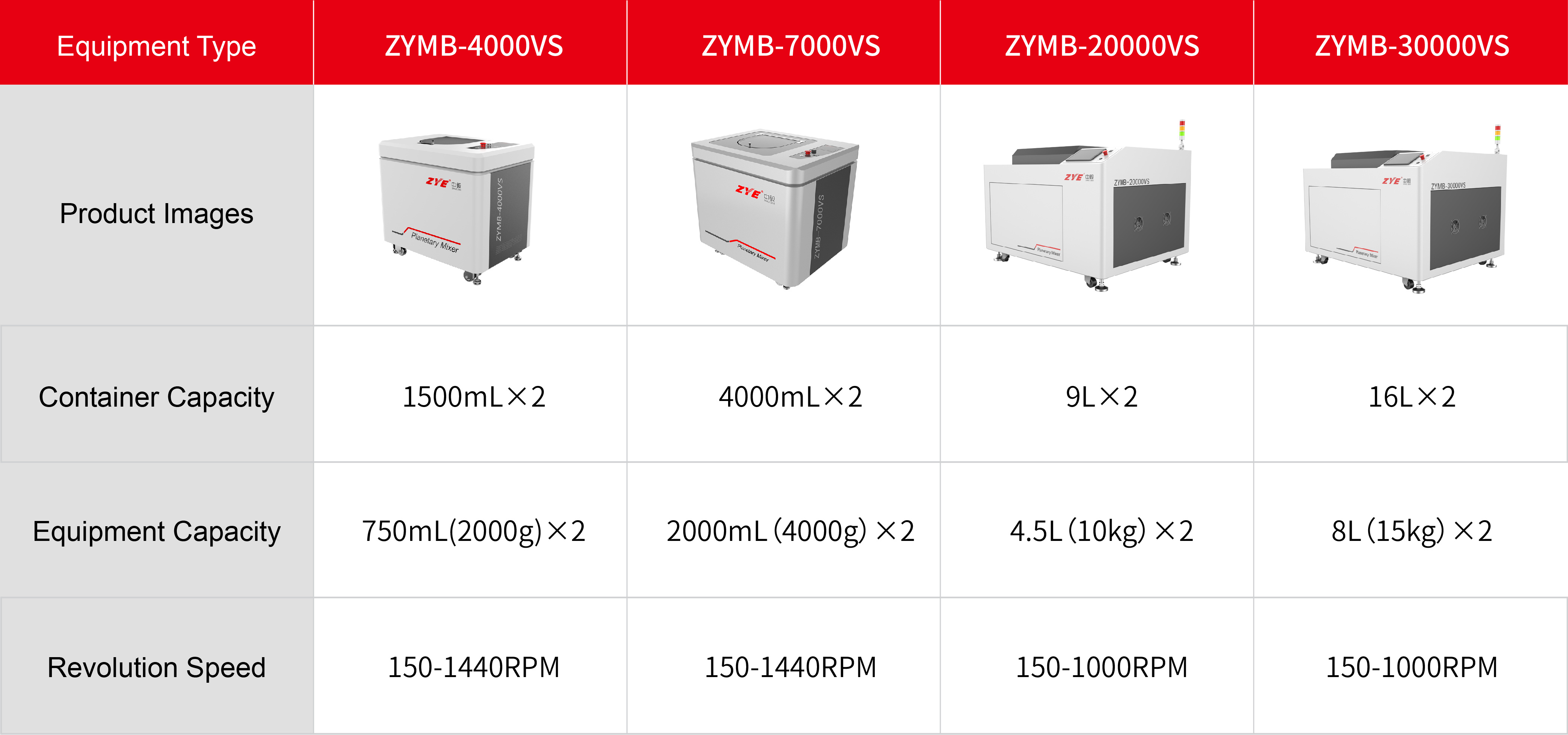

Multiple Models Available

02

Defoaming Mixer For Mixing Materials With Different Viscosities

The vacuum defoaming mixer, also known as a non-contact material homogenizer, operates on the principle of simultaneous revolution and rotation. Utilizing a planetary gear structure, motion control card, and variable-speed control software, it drives the mixing cup in segmented, variable-speed oscillatory motion. This ensures uniform mixing of materials inside the cup while integrating functions such as temperature control, mixing, defoaming, and real-time temperature monitoring.

The device provides non-contact and contamination-free processing, supporting a wide range of viscosities, up to over 1,000,000 cps, significantly improving the efficiency and quality of material development.

In the field of electronics manufacturing, the vacuum defoaming mixer plays a crucial role in enhancing material uniformity, especially in applications with zero tolerance for bubbles, such as semiconductor packaging, new energy batteries, and display technologies. As electronic devices continue to move toward miniaturization and high integration, the demand for defect-free materials is becoming increasingly stringent. The intelligent and highly efficient performance of ZYE's defoaming mixer positions it as a core enabler of next-generation process upgrades.

ZYE’s mixer can handle up to 100 kg of material in a single batch and supports custom configurations such as explosion-proof design and integrated cooling systems, providing real solutions for various production challenges in advanced manufacturing.

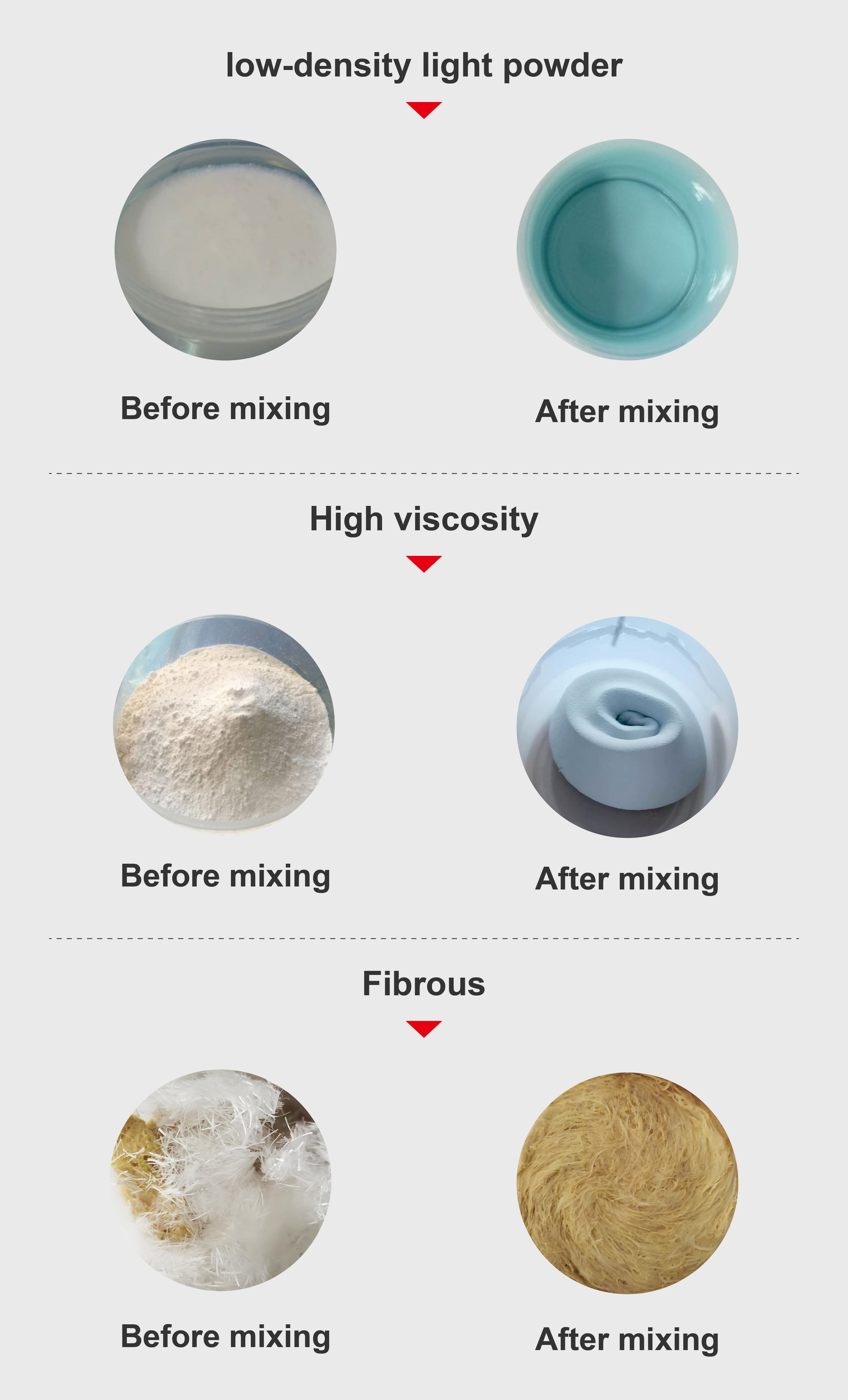

Mixing Various Materials With The Homogenizing Mixer

Multiple Models Available

Meeting Summary

With its "hardcore" innovations in the field of material processing, ZYE provides full-chain empowerment for the industry, from precision equipment to process optimization. Our participation in the exhibition has yielded significant results:

Gaining Market Insight: We acquired a deeper understanding of the cutting-edge technologies and development trends in the electronics manufacturing industry, which helps clarify our company's product R&D direction and market positioning.

Boosting Business Growth: Through our booth displays and on-site communication, we effectively promoted our core products, enhanced brand awareness, expanded our network of potential clients, and injected new momentum into our business growth.

Fostering Innovation: Interactions with industry experts and peer companies have spurred technical cooperation and a collision of innovative ideas, which will be instrumental in elevating our R&D capabilities and market competitiveness.

productronica China 2025 has now come to a close, but the era of smart electronics manufacturing continues to surge forward. We extend our heartfelt gratitude to all the friends who have followed and supported ZYE Technology. We look forward to reuniting with you next year to explore more possibilities in smart manufacturing together!

About ZYE

Established in 2007, ZYE Technology is a premier manufacturer of high-end precision equipment for highly specialized fields in China. We specialize in the research, development, manufacturing, and sales of technologies for mixing, dispersing, degassing, filling, coating, and preparation & testing, dedicating ourselves to providing clients with end-to-end solutions. Our products are widely used in various sectors, including adhesives, inks & coatings, the electronics industry, electronic pastes, new energy, nano-materials, pharmaceuticals, and cosmetics.

Currently, we serve over 2,000 domestic and international clients and have accumulated more than 10,000 experimental reports and records. Our equipment is operational in over 30 countries globally, including Germany, the UK, France, Switzerland, the United States, Canada, Japan, South Korea, Israel, Singapore, and Malaysia.

After nearly 17 years of refinement and development, ZYE Technology has secured over 100 patents, software copyrights, trademarks, and certifications. We are an ISO 9001 Quality Management System certified company and have earned prestigious titles such as "National High-tech Enterprise," "Specialized, Refined, Differential, and Innovative (SRDI) SME," "Gusu Leading Talent in Innovation and Entrepreneurship Enterprise," and "Wujiang District Leading Technological Talent Enterprise."

ZYE Technology adheres to a philosophy that is customer-application-centric and people-driven. We are committed to building a high-end industry brand by following a path of "Brand and Quality," thereby contributing to the advancement of China's equipment manufacturing industry.