Marketing Event | ZYE Technology Shines At The 2025 11th Solar Cell Paste And Metallization Technology Forum, Driving Innovation And Upgrading in The Photovoltaic Industry

2025-03-10 17:38

On March 6, ZYE Technology participated in the 11th Solar Cell Paste and Metallization Technology Forum held in Changzhou. The forum focused on industry frontiers, bringing together numerous experts and corporate representatives to discuss the development trends and challenges in solar cell paste and metallization technologies.

Conference Recap

1. Technological Innovation Trends: 1.The conference delved into the R&D directions of new paste materials, including how to enhance the stability of perovskite battery pastes and optimize the performance of low-temperature silver pastes for HJT batteries. It emphasized breaking through efficiency bottlenecks via material innovation. In metallization processes, laser transfer printing and busbar-free technologies emerged as hot topics, promising to reduce metal consumption and boost battery power.

2. Market Dynamics and Competitive Landscape: With the rapid expansion of the photovoltaic market, there is a surging demand for low-cost, high-efficiency solar cells, accelerating the iteration of paste and metallization technologies. Companies are fiercely competing in R&D investments and market share, with leading firms dominating the market through technological advantages and economies of scale.

3. Policy Guidance and Industry Collaboration: Driven by the "Dual Carbon" goals, policies continue to favor green energy, providing robust support for the photovoltaic industry's growth. The conference called for strengthened collaboration across the industry chain, from raw material supply and R&D to product manufacturing, to form efficient synergy mechanisms and collectively tackle industry challenges.

Recap

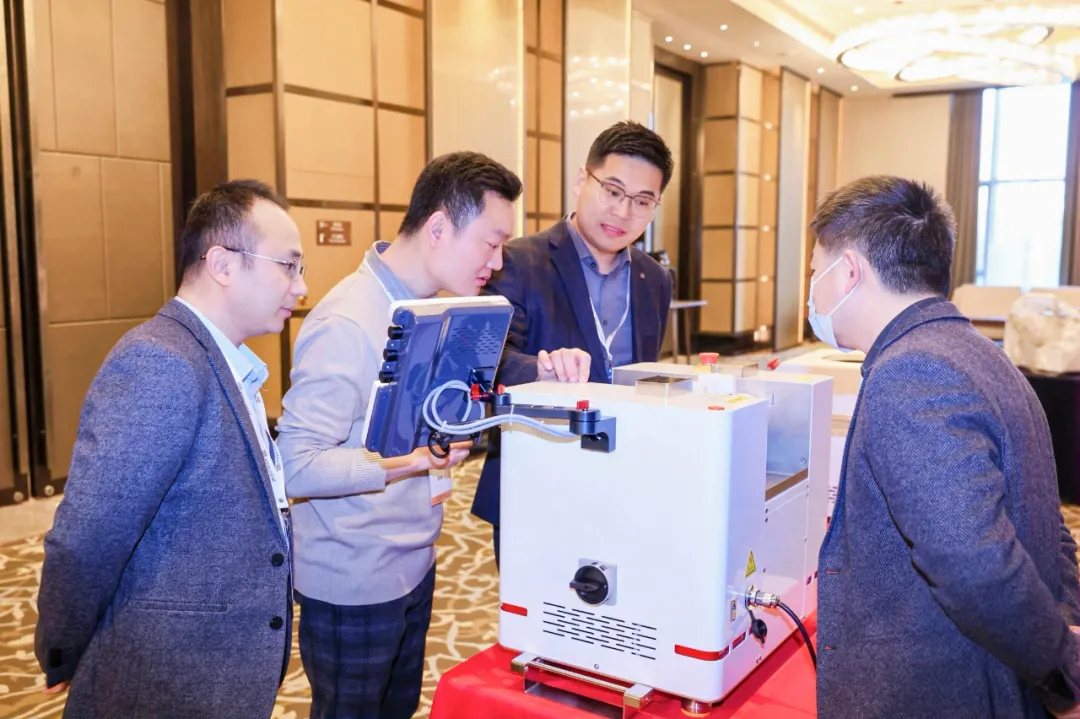

At the forum, ZYE Technology's booth attracted significant attention. Through interactive demonstrations and case studies, the company showcased how its equipment enhances the performance and stability of photovoltaic pastes. Attendees witnessed the exceptional performance of precision three-roll mills in particle refinement and conductivity optimization, as well as the efficient capabilities of non-invasive planetary centrifugal mxer in mixing and degassing. In-depth exchanges with industry experts further elevated ZYE Technology's technical influence in the photovoltaic sector. We look forward to adding value to the forum with our professional expertise!

During the forum, the ZYE team, with their professional acumen, provided detailed technical explanations to visitors and offered customized solutions tailored to the photovoltaic industry's needs. Their professional demeanor won recognition from new customers, with many expressing intentions to collaborate and exchanging contact information, laying a solid foundation for future business expansion.

Technical Advantages

In photovoltaic cell metallization processes, the uniformity and particle distribution of the paste directly determine the cell's efficiency and cost. Traditional equipment struggles to meet high-precision demands, but ZYE Technology brings revolutionary breakthroughs.

01

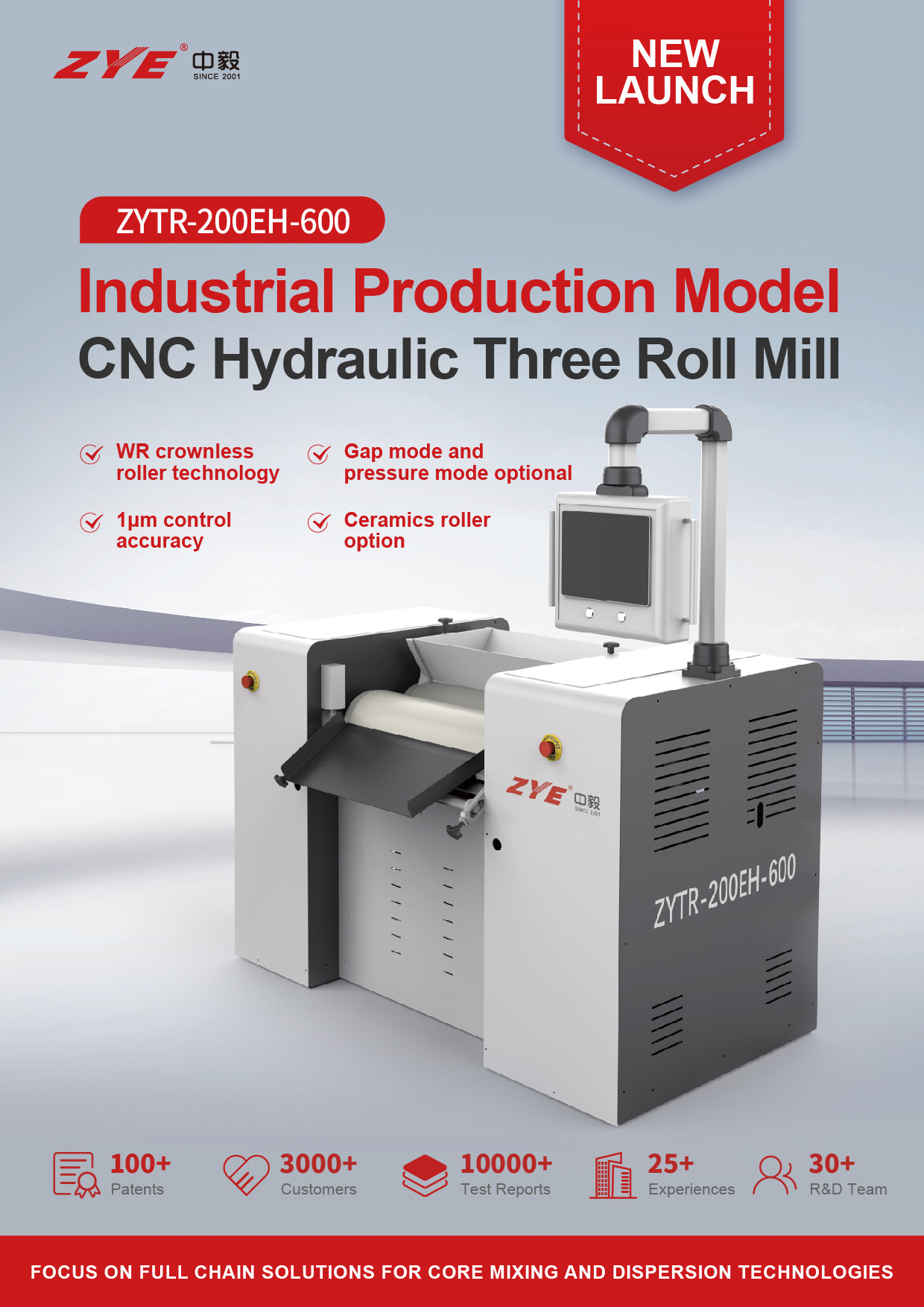

Application of Three-Roll Mills in the Battery Paste Industry

Precision three-roll mills play a crucial role in the production of photovoltaic silver paste, mainly reflected in the following aspects:

1. Uniform Dispersion: Photovoltaic silver paste consists of silver powder, glass powder, organic carriers, etc. The three roll mill ensures the stability and consistency of the silver paste by uniformly mixing these components through high shear force.

2. Particle Refinement: The three roll mill refines silver powder particles to nano or sub-micron levels through the squeezing and shearing between rollers, enhancing the paste's conductivity and printing performance.

3. Improved Conductivity: Refined particles enhance the paste's conductivity, boosting the photovoltaic cell's conversion efficiency.

4. Enhanced Printing Performance: The milled paste has better fluidity, suitable for screen printing, ensuring precise electrode patterns and reducing defects.

5. Increased Stability: Uniformly dispersed paste is more stable during storage and use, reducing sedimentation and agglomeration, and extending shelf life.

6. Improved Adhesion: The milled paste adheres more closely to the substrate, enhancing the electrode's mechanical strength and durability.

7. Optimized Optical Performance: Refined silver particles reduce light scattering, improving the cell's light absorption efficiency.

For every three roll mill from ZYE, the reduction in particle size and the dispersion of agglomerates are achieved through the combined action of the rolling pressure between the rollers and the high shear force generated by the different rotational speeds of the rollers. Since all the material is filled into the gaps between the rollers, the particle size can be precisely controlled with a narrow distribution. By adjusting the roller gaps, the particle size can be easily and accurately processed to the micron level, significantly enhancing the performance of photovoltaic silver paste. This, in turn, improves the efficiency and reliability of photovoltaic cells, a feat that is relatively difficult to achieve with other processes.